Polymeric composites are increasingly being used on power grids for outdoor high-voltage insulation in place of conventional glass or ceramic insulators. Silicone-based materials are lightweight, heat-resistant, chemically stable and hydrophobic, leading to long-term performance and cost-effectiveness during production, installation and maintenance.

In general, composite polymer insulators are composed of a polydimethylsiloxane (PDMS, silicone rubber) polymer matrix with dispersed inorganic fillers. Addition of silica and alumina trihydrate (ATH) improves physical strength and electrical/heat resistance of these materials, respectively.

Silicone rubber has unique surface properties that allow it to retain its hydrophobicity during ageing from contamination, climatic conditions and high voltage stress. Time-dependent restoration of hydrophobicity occurs under dry conditions through diffusion of low molecular weight siloxanes from the bulk of the polymer matrix to the surface. It is well known that the exceptional insulation properties exhibited by silicone rubber are due to their typical chemical composition. However, details of how insulation properties may be lost during the ageing process are less understood.

Although outdoor high-voltage silicone composite insulators show exceptional properties, they are also vulnerable over time to natural degradation processes under standard operating conditions. Ageing is a gradual process that can result in a loss of function and eventual breakdown of the materials. Repeated breakage and reformation of the bonding in the material lead to microscopic and macroscopic changes in the material’s appearance and performance.

For example, discoloration is often the first sign of ageing, which can be accelerated by UV and heat, leading to formation of free radicals. Factors that contribute to ageing include heat, humidity, UV radiation, wind, dust, acid rain, chemical pollutants, temperature and microbiological organisms. Salt is also a significant factor in coastal areas.

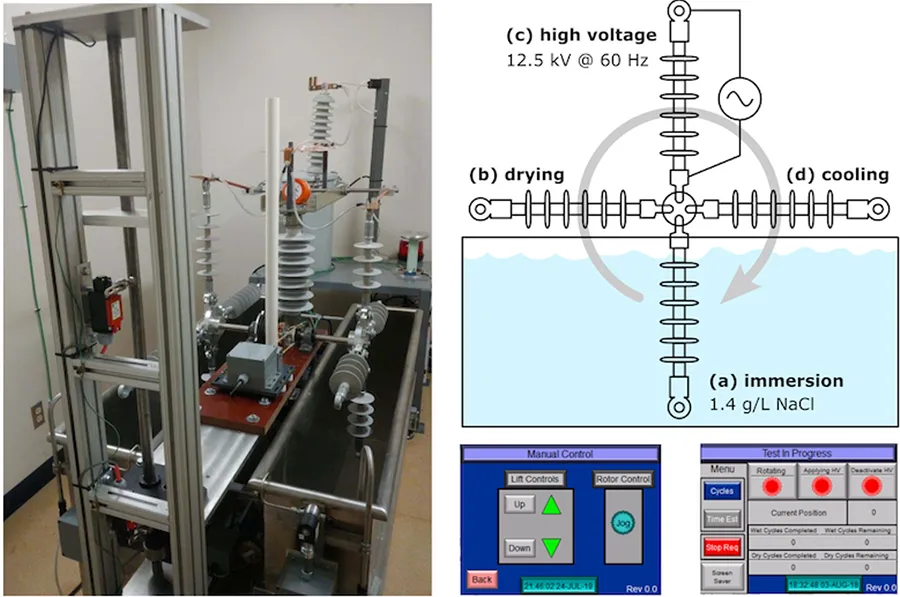

Numerous studies have been conducted to understand the degradation and ageing mechanisms of silicone rubber insulators in both natural conditions and in accelerated ageing environments, including electrical, corona, and ultraviolet testing. Material characterization techniques that have provided insight into the changes of the underlying molecular and macroscopic structure include scanning electron microscopy, energy dispersive X-ray analysis, thermogravimetric analysis, contact angle measurements, X-ray photoelectron spectroscopy, mechanical testing and attenuated total reflectance infrared (ATR-IR) spectroscopy.

ATR-IR spectroscopy is particularly useful since it can help determine the degree of degradation caused by different electrical and environmental effects. It has been used to characterize high-voltage composite insulators of various ages and establish a correlation between extent of degradation and residual insulator service life. Interpretation of the resulting IR spectra can be significantly aided by application of two-dimensional correlation spectroscopy (2D-COS), a potent tool for extracting hidden information in conventional one-dimensional ATR-FTIR and Raman spectra.

Plan to be present at the 2025 INMR WORLD CONGRESS in Panama. Prof. Dennis Hore and researchers from ASAsoft and the University of Victoria in Canada will introduce a new chemical/electrical stress and associated characterization technique – termed μ-IPT – that seeks to bridge the gap between controlled environment laboratory testing and the ability to use material derived from actual insulator samples. They will explain how integrating experimental evidence with predictive computational tools and manufacturing data enables development of a comprehensive digital twin framework, thereby providing proactive assessment of polymer insulator reliability under diverse service conditions.