In the case of overhead power lines, three basic principles help define environmental sustainability:

• using less materials (apart from conductor);

• avoiding materials or processes that pose risks to the environment; and

• installing as much conductor as required to keep losses to a minimum.

This edited past contribution to INMR, Jonathan Woodworth proposed that EGLA type arresters contribute to improved sustainability of transmission line design as well as operation.

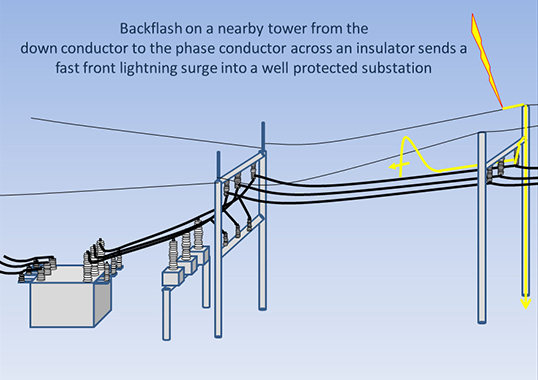

Power losses from shield wires can be eliminated by applying line arresters to provide necessary lightning protection. Calculation of losses due to shield wire can be made both with and without ‘segmentation’ – an installation option where shield conductors are insulated from towers and terminated every mile (circa 1.5 km) in order not to form a continuous conductor over the line’s full length.

Losses due to overhead shield wire are a function of load current such that the higher the load current in the phase conductors, the greater will be these losses. In order to project life cycle losses on any new line, an analysis needs to assume some load current. In this case, conservative numbers are applied for a 100 mile (160 km) long 345 kV line with average current of 1000 amps and equipped with two shield wires. Assuming the right shield wire has an integrated optical fiber and is 0.61 ohms per mile while the left is aluminum clad steel and 2.4 ohms/mile, resulting steady state currents induced into these shield wires would be 41 and 70 amps respectively. That translates into roughly 708 kW of steady state losses. Given this scenario and the typical 30 year life of towers and shielding, cumulative losses due to shield wires would have a present value of about $ 3.8 million, based on an assumed energy cost of $ 50/MWh.

If externally gapped line arresters that are approximately equal in material and installation costs to shield wire had been installed to protect this same line, there would be no energy losses. Not only does such a design solution seem attractive from an economic perspective, it is also more sustainable environmentally because it requires fewer materials and lower costs to operate.

Of course, before considering such an option most line designers would need to know the reliability of a line lightning arrester. In the case of the more common type that does not include a series gap, finding the answer might prove difficult. But if the externally gapped line arrester (EGLA) is considered, where the arrester is never energized at line voltage, the answer is simple. Since there is no external leakage current and no electrical stress imposed on an EGLA’s active parts over its full service life, reliability is inherently high. For example, typical annual failure rate could be on the order of only one unit per million. Indeed, reliability of EGLAs is uniformly high and their service lives cover many decades. If an EGLA is used to replace shield wire, the issue of arrester reliability is no longer relevant when estimating line reliability.

Therefore, consider EGLAs in place of shield wires and save on operating costs with reduced adverse environmental impact.

[inline_ad_block]