Coming at the 2025 INMR WORLD CONGRESS

Overhead transmission line design guides devote chapters to mitigating shielding failures, i.e. where lightning terminates directly on an energized, insulated phase. When recommended protection systems such as overhead groundwires (OHGW) are fitted, they capture lightning strokes of both small and large peak amplitude. However, if the product of the lightning peak current and “wave impedance”1 at a structure exceeds insulation strength, there may still be a flashover from structure to phase. (Note: Wave impedance is the parallel combination of the footing impedance and the surge impedance of all OHGW and arrester protected phases, corrected for mutual surge impedance coupling, and ignoring the tower surge response. The wave impedance persists for two span travel times when current is impressed at tower top, and falls after reflections arrive from adjacent grounded structures.)

As the power system energy sustains this arc, a momentary fault must be cleared by other protection systems such as automatic circuit breakers or reclosers. These “momentary” outages dominate the economic impact of power system reliability. A short duration interruption of three to ten power frequency cycles on a transmission line is seen as a severe voltage dip by many customers. These momentary dips lead to equipment damage costs for industrial customers with large loads that are not supported by energy storage.

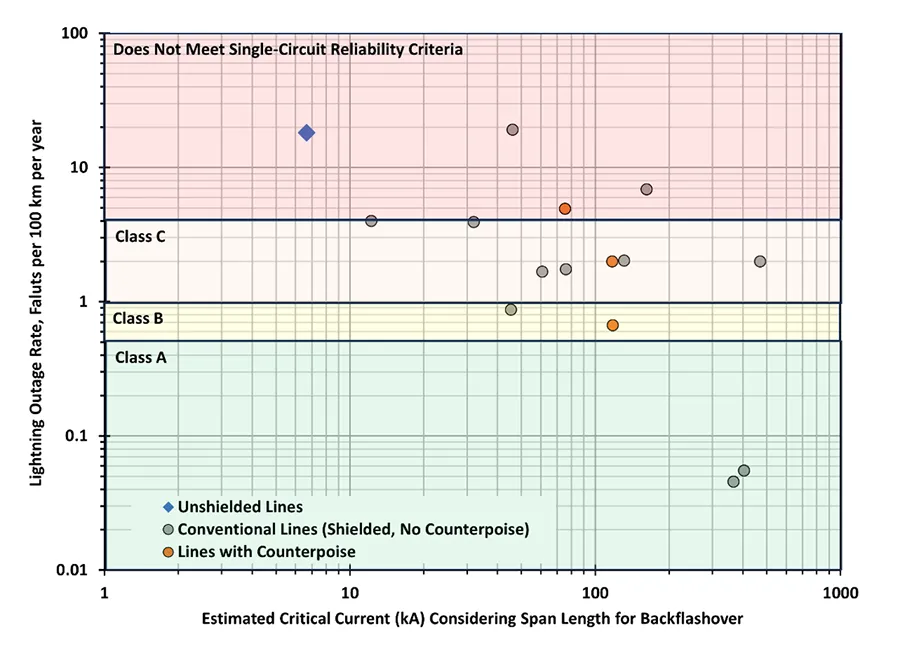

Well designed lightning protection reduces the number of momentary outages, without adding other risks of failure. Design guides rely on IEEE Standards and CIGRE references for the series of calculations made to establish shielding failure rate (SFR) and back-flashover rate (BFR). These terms are added to establish total lightning outage rate, expressed in units of outages per 100 km of line length per year. While ground flash density (Ng, in flashes per km2 per yr) can vary considerably (e.g. by a factor of 1000:1 across the globe), utilities tend to adapt new overhead line designs to deliver about the same outage rates. For example, one historical overhead line security classification includes:

• Class “C”, < 4 lightning outages per 100 km per yr

• Class “B”, < 1 lightning outage per 100 km per yr

• Class “A”, < 0.5 lightning outages per 100 km per yr

Class “A” security is a design target for ultra-high voltage (UHV) lines at system voltage 1000 kV AC. In Japan, the 500 kV system achieves Class “A” security, and their 187-275 kV systems often achieve Class “B”, based on ten-year average outage rates from 1980 to 2020. With reduced insulation level (i.e. distance between arcing horns), between 1980 and 2010 their 110-154 kV systems achieved Class “C” security, while their 66-77 kV systems did not.

To improve security, considerable investment was made to improve lightning outage rate on 66-77 kV and 110-154 kV systems. For example, installation of 300,000 surge arresters (LSAs) on 66 and 77 kV systems was completed in 2011, rising to 370,000 LSAs by 2020 on about 38,000 km of line length. The benefits were clear. The single-circuit outage rate was cut in half, with an average of 2.1 outages per 100 km per year over the period from 2011 to 2020. This showed that it is feasible to achieve Class “C” reliability for this voltage class. When considering only double-circuit faults from lightning, all overhead transmission lines in Japan have demonstrated Class “A” reliability since 2011.

Lightning Performance, 60-69 kV Lines of the 1940s & 50s

In 1955, the Ohio Brass Company (now Hubbell Power Systems) collected and published descriptions of many overhead transmission lines, including those with system voltage of 60-69 kV. Each line description had tower blueprints and a list of features relevant to lightning performance, including number of days with thunder pear year (TD), positive critical lightning impulse strength (+CFO) of insulation and average annual lightning outage rate.

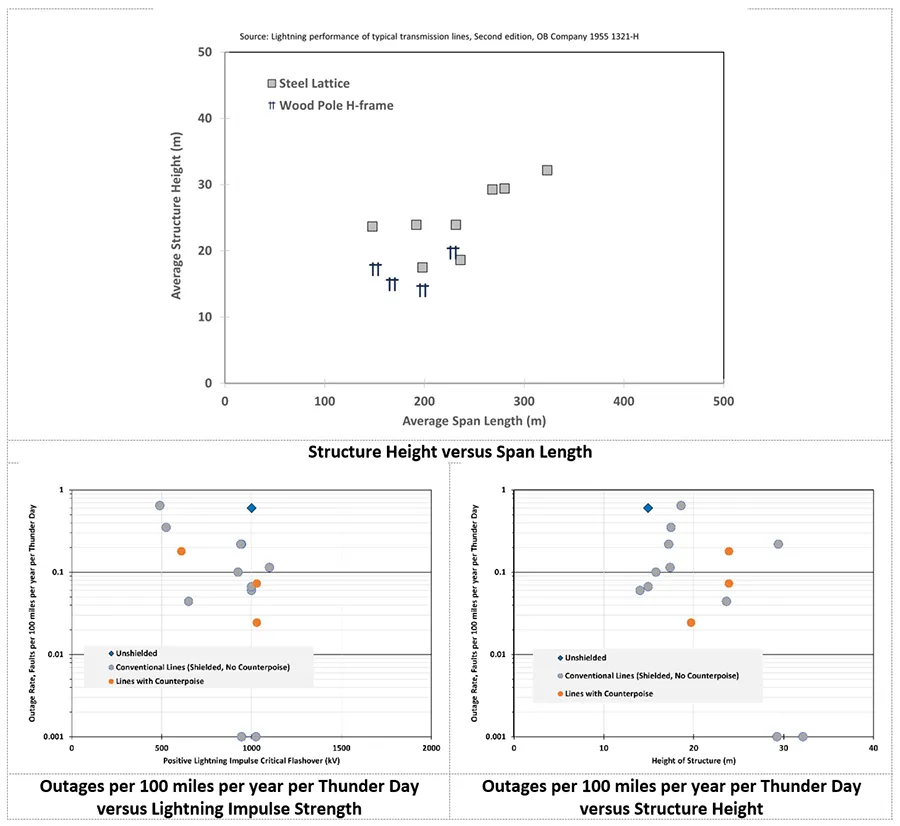

It is helpful to review the details in this resource. Even if the 60-69 kV transmission lines that delivered good service in 1955 are now obsolete, these lines may be considered to be rebuilt for higher power. Physically, all lines had +CFO > 490 kV, which is considered adequate for resisting any lightning that does not terminate directly on a phase. Half of the 60-69 kV lines achieved this impulse strength with a combination of strings of porcelain insulator discs in series with wood crossarms or poles. Some lines used 10 or 11 standard 146 x 254 mm discs to achieve >900 kV +CFO. Fig. 1 shows that the lines with higher +CFO had lower outage rates, using an old-fashioned normalization based on TD.

Fig. 1 also shows that the 60-69 kV lines with average structure height < 20 m used H-frame construction made from two wood poles and a single crossarm. The median span length with wood H-frame structures in Fig. 1 was 168 m, compared to 234 m for steel lattice structures.

In 1955, the electric utility industry relied on meteorological station measurements of TD to normalize performance against local lightning activity. With the data provided, it was possible to estimate a “critical current” Icrit for backflashover (kA) from provided values of lightning impulse strength (kV), average footing resistance (Ω) and factors accounting for parallel overhead groundwires on shielded lines. Fig. 2 shows a rough downward trend in normalized outage rate as Icrit increases.

When the critical current Icrit > 200 kA, it is often considered to be lightning proof. Fig. 2 shows good performance for two of the three 60-69 kV lines with Icrit > 200 kA and the majority of the 60-69 kV lines achieved at least Class-C security.

Lightning Performance, 60-69 kV Lines Upgraded by 1955

It is helpful to review the measures adopted to improve lightning outage rates of 60-69 kV lines before 1955. These measures are described below to aid in visualizing the parameters in a simplified model for the peak magnitude of the first negative return stroke (RS) that causes a fault.

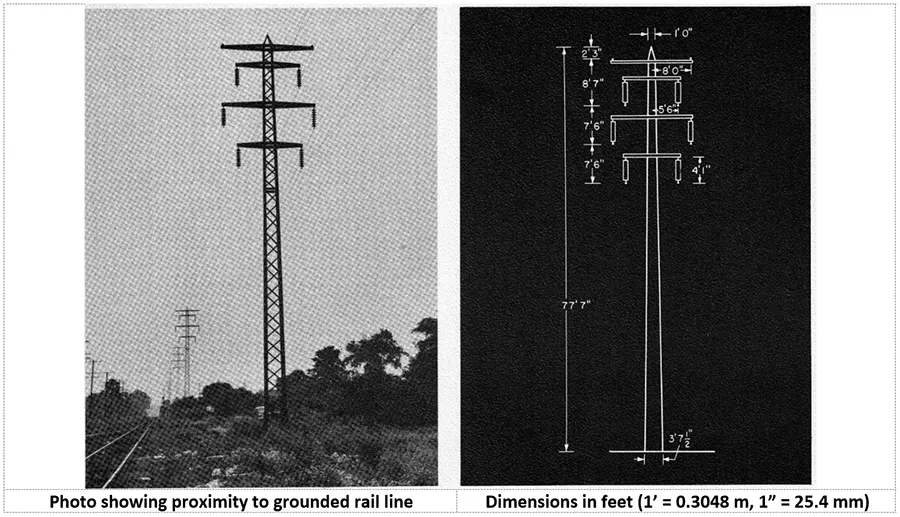

Negative Shield Angle

When OHGW are placed directly above or outboard of the phase conductors, they offer better protection than configurations where the OHGW spacing is less than the horizontal phase-to-phase spacing. The 66-kV line of the Philadelphia Electric Company operated for 37 years with the shielding configuration shown in fig. 3. Each of the OHGW extends 8’ (2.44 m) out from the central lattice structure. The top phase conductors of each circuit are spaced 5.5 ft (1.68 m) when the insulators are vertical. The shielding angle is negative (-16), since the top phases are tucked inside of the protection zone of the OHGW. The shielding angle to the middle phases is 0 as the OHGW on each side is directly above. This line was therefore considered to be well shielded.

With +CFO = 650 kV from 8-disc strings of 127 x 254 mm (spacing x diameter), this line achieved a lightning fault rate of 0.9 per 100 km per year, giving Class B security in a region with an average TD = 31.7 days per year. For future reference, the “Coupling Coefficient” Cn to the top-phase conductors was 0.44. If the OHGW voltage is 1000 kV, the phase voltage will become 440 kV and the voltage across the insulation will be (1000 – 440 = 560 kV).

This factor reduced stress on insulators and improved lightning performance. When more OHGW are present and they are close to the phases, the value of Cn increases. A convenient spreadsheet model for the calculation is available. Since the middle and bottom phases in Fig. 3 are farther from the OHGW their mutual surge coupling coefficients are 0.35 and 0.29 respectively.

Insulator Grading Rings

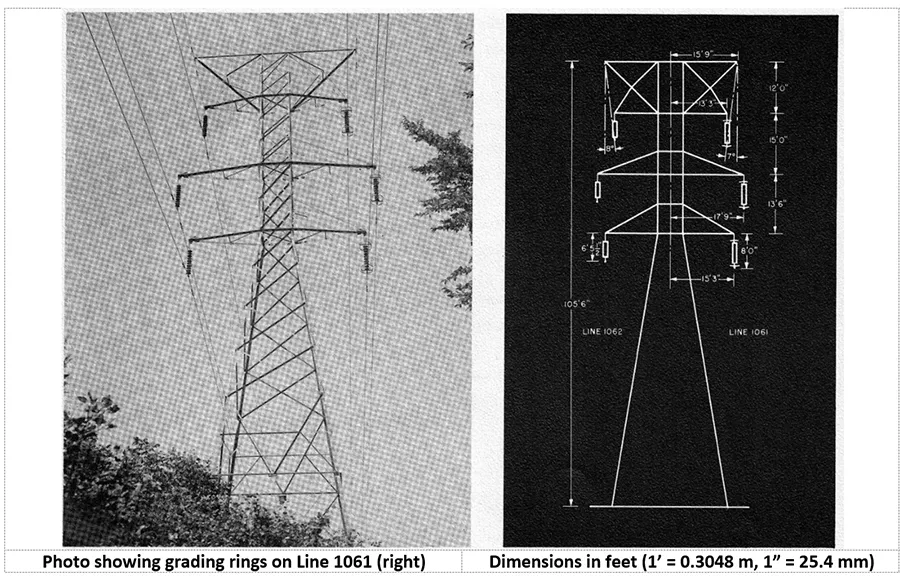

Grading rings are fitted to polymeric insulators to improve service life and used to mitigate damage from power system arcs. For example, the engineers at Cincinnati Gas & Electric wanted to evaluate the merits of corona rings in 1938, by fitting them at each end of the ceramic disc insulator strings on Line 1061 in Fig. 4. These rings at line and ground end were not used on the insulators of Line 1062 to the left, which was completed 10 years later.

With average footing resistance Rf=2.3 Ω and +CFO = 945 kV, neither of the 66 kV circuits in Fig. 4 had any lightning faults, despite a high local value of TD = 51.4 days per year in Cincinnati. Part of the good performance of this line may also have been attributed to its use of negative shield angles, -8° on Line 1062 and -7° on Line 1061 to accommodate the extra length of the grading rings (8’ – 6’ 5.25” or 470 mm). However, as an introduction to estimating the critical current concept, it would require a lightning surge of 410 kA flowing in 2.3 Ω to generate a surge voltage of 945 kV. This is a low probability event, since lines with critical current > 200 kA are generally considered lightning proof.

Sacrificial Low Voltage Circuit

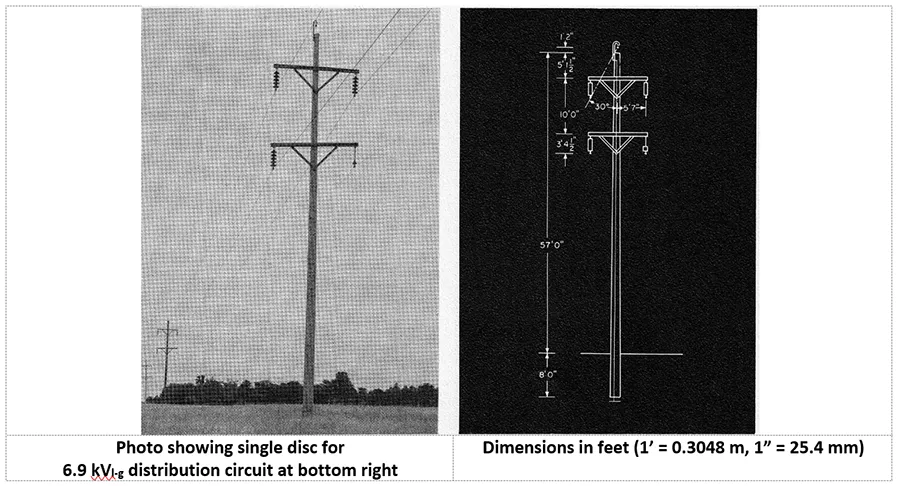

The photo and drawing in Fig. 5 show single-pole construction with a single OHGW at the top of the pole, providing a typical +30 shield angle to the top two phases. The line description notes that the fourth conductor is one phase of a 12/6.9 kV distribution system that is using the OHGW as a neutral.

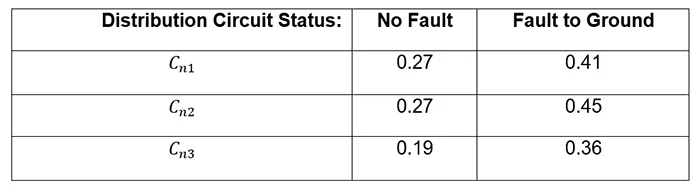

When lightning terminates on this line, even with low footing resistance of Rf=4 Ω, the median RS current of 30 kA would generate a 120 kV impulse voltage that will backflash from pole to the distribution circuit. Its lightning performance will be poor but every time the distribution circuit faults to ground, it protects the transmission circuit by raising the coupling coefficients, as in Table 1.

When the distribution line faults to ground, there is a large improvement in Cn3 in Table 1 for the bottom phase of the 67 kV line, which is at the same height as the distribution line. This height is the crossover level between an underbuilt GW (located below all the phases) and an embedded GW (located above one or more phase). The benefits of underbuilt and embedded GW for 345-kV double circuit lightning performance, including effects of corona, are found in Fig. 9 of IEEE Standard 1243.

With a modest TD level of 28 days/year, the line in Figure 5 achieved Class-C reliability with 2.0 lightning outages per 100 km per year. While Figure 5 shows that only five standard discs were used in suspension, the +CFO was increased to 1100 kV by using unbonded crossarms with 1.7 m wood path.

Underbuilt Groundwire (UBGW)

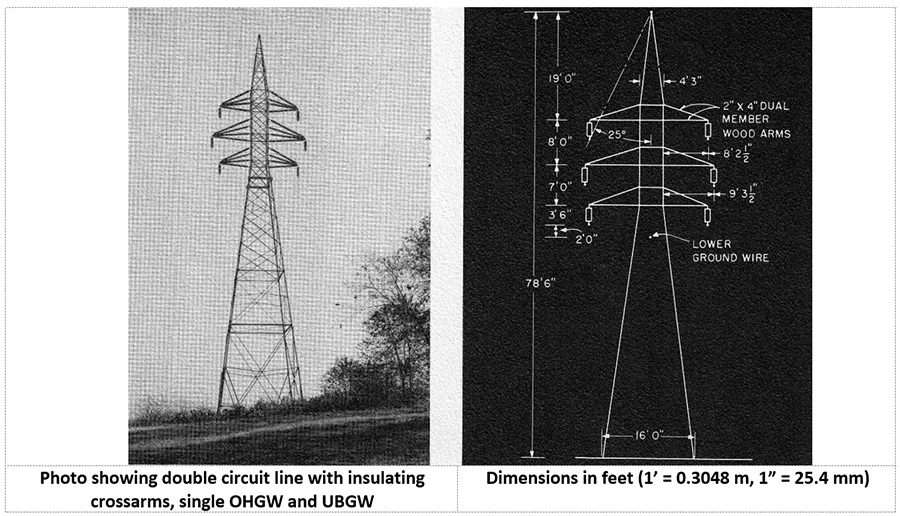

Poor lightning performance in the 1930s of the Duquesne Light Company’s 69 kV ring lines surrounding Pittsburgh led to rebuilding in 1941-42 that variously:

1. Added a peak to the tower top to raise the single OHGW, providing reduced shielding angles of 19 to 25;

2. Installed an underbuilt groundwire (aerial counterpoise) to increase the coupling effect;

3. Reduced the tower footing resistance below 25 Ω, with average value 10 Ω, using short radial counterpoise and additional vertical ground rods;

4. Increased insulation strength from +CFO = 610 kV with 6 standard discs to:

5. 1030 kV by replacing steel arms with dual-member 5’ (1.52 m) wood arms, or

6. 1025 kV by using 11 discs.

Fig. 6 shows the dual-member wood arms and location of the UBGW for a rebuilt line that achieved Class-C security of 2 outages per 100 km per year in a region with TD=44 days/year.

The location of the UBGW in Fig. 6, in concert with the elevated single OHGW, may have been optimized to deliver the same computed values of Cn≅0.33 at all 6 phase conductors.

Plan to attend the upcoming 2025 INMR WORLD CONGRESS in Panama City, Panama this October. Lightning protection expert, Dr. William Chisholm, will explain that the decision to apply line surge arresters (LSAs) in difficult terrain is determined by estimates of local ground flash density and the critical currents that cause flashovers. When direct stroke protection is provided using overhead groundwire (OHGW), the critical current for backflashover from grounded structure to insulated phase depends primarily on soil resistivity.

He will also present simplified models of lightning backflashover and transient grounding that provide quantitative insight into the relative performance of various treatment options.