Modern cable accessories and connectors are being manufactured using a broad range of silicone elastomers and auxiliary materials – from fluids to gels to pastes. In this edited contribution to INMR, Dr. Jens Lambrecht of Wacker Chemie in Germany explains how elastomers that contain electrically conductive fillers (generally referred to as ‘conductive silicones’) play an important role in design and performance of these types of components.

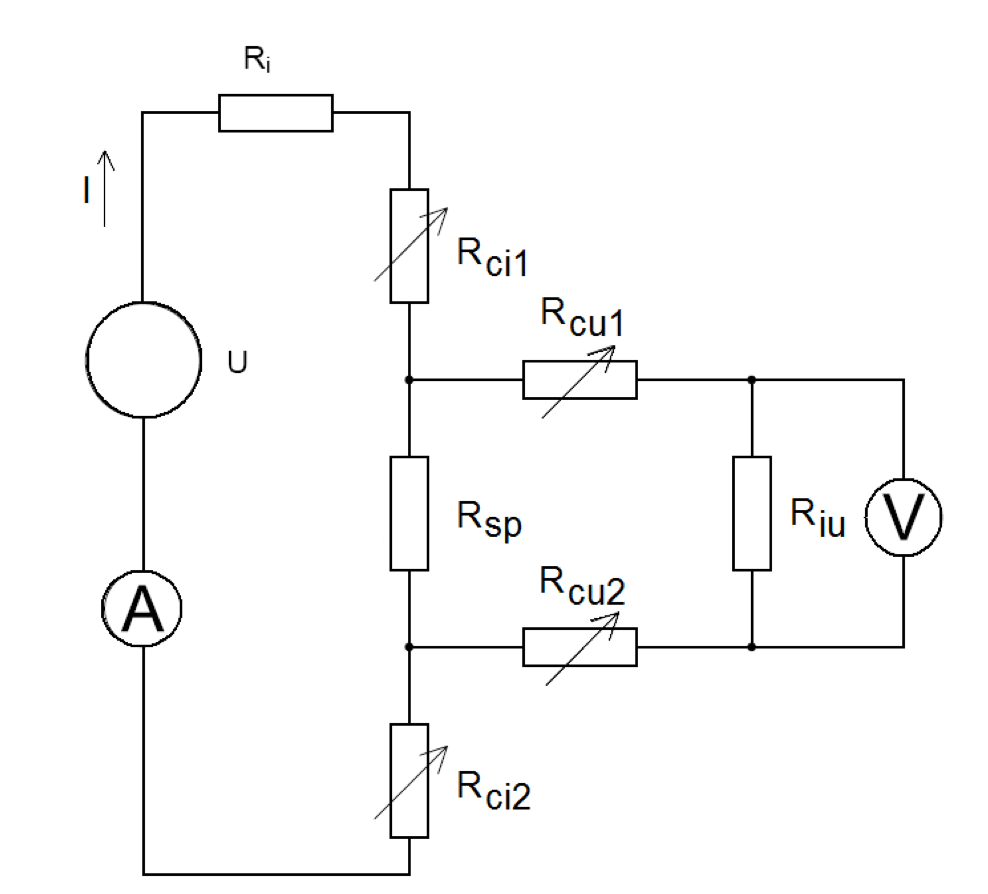

Experience has shown that proper measurement of the specific volume resistivity of conductive silicone materials can present a challenge for users. Attempts to determine this key parameter with the aid of multimeters or other two-wire devices usually do not deliver useful results because the typical resistivity of electrically conductive silicones for power applications falls in the range some 10 cm. Proper measurement therefore requires a four-wire device with independent circuits for current and voltage. The circuit diagram of the measuring circuit for such a device and the test specimen looks like what is shown in Fig. 1 below.

Ri – Internal resistance of voltage source

Rci1, Rci2 – Resistance of contacts between current-feeding electrodes and specimen

RSp – Resistance of specimen (in area between voltage electrodes)

Rcu1, Rcu2 – Resistance of contacts between specimen and voltage-measuring electrodes

U – Voltage

I – Current

RiU – Internal resistance of voltage measuring device

With Umax being maximum available voltage of the source, the main conditions for accurate measurement with low risk of error are:

Riu >> Rcu1 + Rcu2 and Umax > (Rci1 + Rsp + Rci2) x I

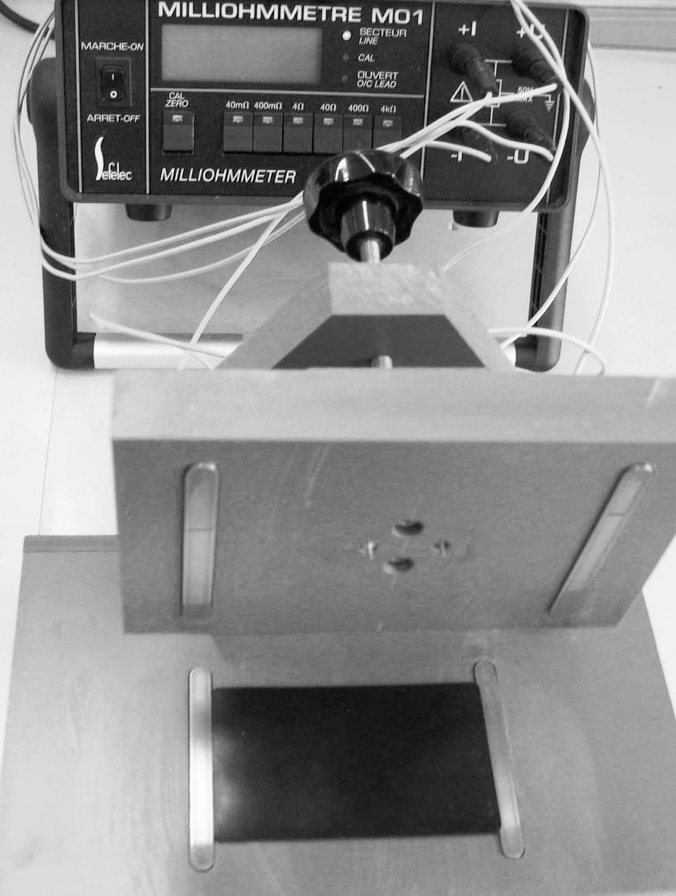

The internal resistance of the voltage-measuring device needs to be much higher than the sum of the resistances of the contacts between the specimen and the voltage-measuring electrodes. Experience shows that gold-plated pin electrodes work well if they are pressed into the volume of the elastomer. On the other side, a stiff and sufficiently high test voltage is required and one that is much higher than the sum of the voltage drops at the current-feeding contacts and at the specimen. Experience shows that multimeters with built-in battery sources usually do not fulfill these requirements. That is why a four-wire milliohmmeter with an adjustable current source is the most suitable device to measure resistance and calculate resistivity of silicone materials with electrically conductive fillers.

[inline_ad_block]