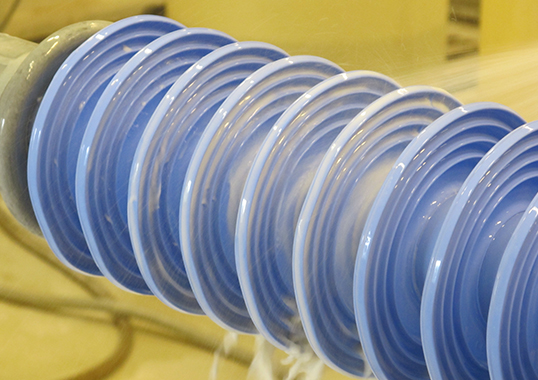

Application of RTV coatings to glass and porcelain insulator discs was originally used only by utility maintenance departments for mitigating problems encountered in service. However, it has since reached a point where it can no longer be considered only a marginal approach for solving localized problems but rather a fundamental part of new transmission line design.

A major factor in this development came from the decision more than 20 years ago to establish a product whose performance was based on an industrial process. This process saw insulators coated in the factory under carefully controlled conditions instead of in the field where variable outdoor weather often compromised consistency and quality of application and therefore long-term product performance.

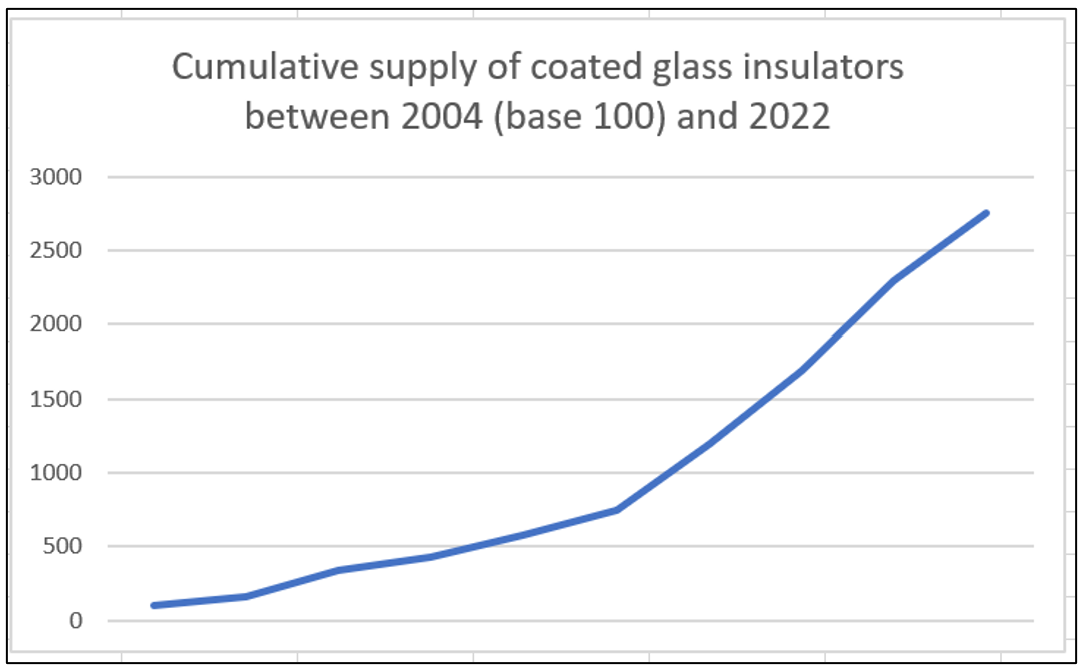

Fig. 1 shows the actual trend seen by major suppliers (in this case Sediver) in the development of silicone-coated glass insulators and provides clear evidence of this growing demand. These numbers, even from only one supplier, show a 30-fold growth over a period of only about 20 years.

Based on the above, a coated insulator is today no longer defined as only adding a coating to an insulator but rather as a specific type of insulator that incorporates addition of a silicone material, an application process as well as the insulator itself – all under the responsibility of the manufacturer.

Given this huge expansion, a need has been identified for clear, well-defined material and testing specifications. This in turn has led to efforts currently in progress from work being done in IEC 36 / 535, where experts are drafting a standard for RTV coated insulators. Moreover, CIGRE has recently published two excellent base documents on coatings: Technical Brochures TB 837 and TB 838.

The need for a standard is based on recognition that the ageing process of a silicone material comes with several changes in its properties. Loss of hydrophobicity, for example, whether partial or complete, progressively allows increased leakage current and can eventually lead to an erosion process. This in turn has led to numerous attempts to define what is a suitable erosion test.

Plan to attend the upcoming 2023 INMR WORLD CONGRESS in Bangkok where a range of experts will discuss topics related to performance of coated insulators. For example, Jean-Marie George will present a paper that describes the various options available for evaluating the ageing and electric degradation of silicone coating materials used for glass and porcelain insulators. Similarly, Ahmad Al-Thagafi of the GCCIA will review performance of coated insulators in the severe service conditions found across Saudi Arabia.

[inline_ad_block]