Hydrophobicity is the single most valued property of polymeric materials used for outdoor insulation since it provides enhanced pollution performance. Since the 1980s, a large body of research at universities and by insulator manufacturers has therefore been devoted to investigating and better understanding this property. So far, only silicone rubber polymers have demonstrated that hydrophobicity can endure over the full service life expected of an insulator.

CIGRE Technical Brochure (TB) 442 describes a variety of test methods to quantify retention of hydrophobicity under simultaneous electrical and electrolytic stress and also hydrophobicity recovery and transfer.

Retention of Hydrophobicity

The basic idea behind a new test – the Dynamic Drop Test – considered the following basic requirements:

• a relatively short test duration;

• simple geometry of the test specimen;

• high test reproducibility;

• low scatter of results;

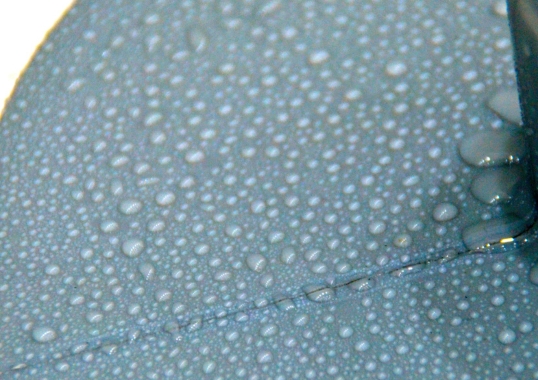

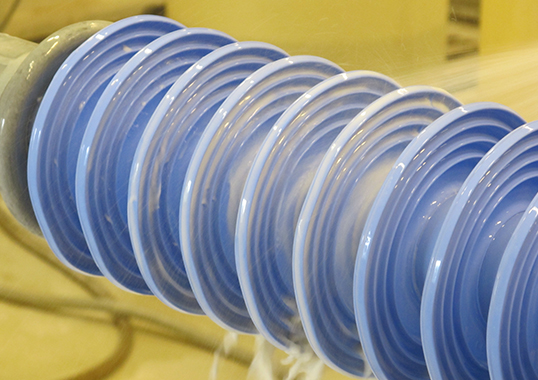

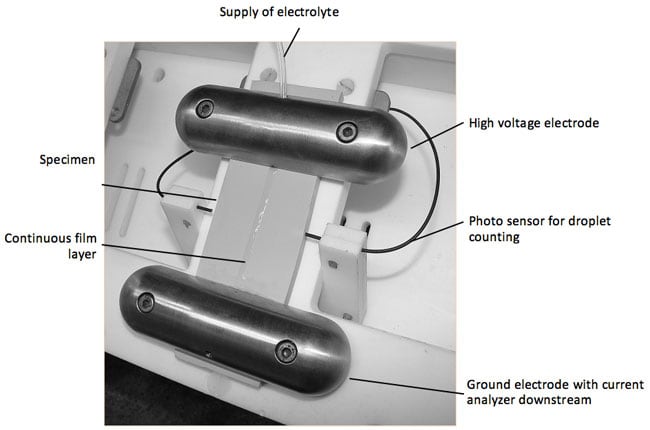

The test employs the same basic principle as the Inclined Plane Test (IEC 60587), however has different electrode geometries and an electrolyte (without a wetting agent) that is applied to the top surface of the plate-shaped specimen, as in Fig. 1. What is then evaluated is how much time is needed to achieve a continuous path of water between the electrodes. Depending on test voltage applied (typically between 4 and 5 kV), a leakage current of 2 mA will demonstrate loss of hydrophobicity.

The Technical Brochure also provides results with Dynamic Drop Tests conducted using an international Round Robin methodology by participants in Germany and Japan. These results confirmed that the test has high reproducibility among the different participating laboratories and might well eventually become a standard. However, because of the relatively limited experience with this test, criteria or material classes cannot yet be defined since it is clearly better to have comparative results with other families of polymers as well.

Hydrophobicity Recovery

An investigation was also performed to determine whether this test can be used to also evaluate recovery of hydrophobicity after certain stress treatments (e.g. corona or UV). Basically, plate-shaped specimens that lost hydrophobicity were then investigated after a certain rest period. Generally, hydrophobicity recovered and the continuous water path soon changed to one of down-rolling droplets.

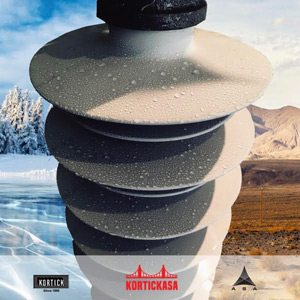

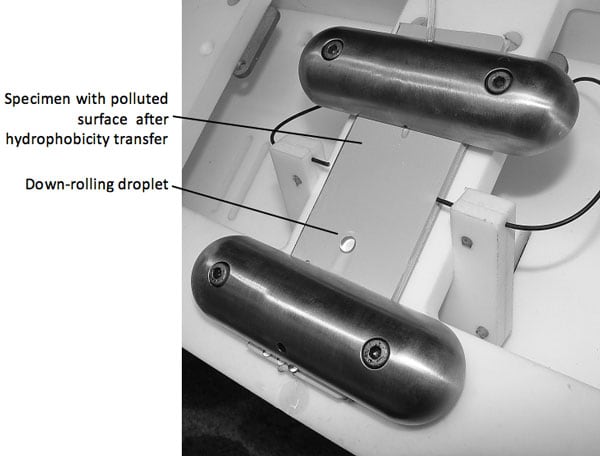

Hydrophobicity Transfer

The Technical Brochure also describes application of a defined artificial pollution layer and a methodology to evaluate droplets formed after transfer of hydrophobicity into this layer. Test reproducibility was confirmed by means of Round Robin testing conducted in Germany, Japan and Switzerland. Furthermore, additional internal investigations were carried out to learn whether the principle of the Dynamic Drop Test could also be used to quantify hydrophobicity transfer. Based on work performed by a past CIGRE WG dealing with investigation of pollution layers and application methods to improve the reproducibility of pollution tests for polymeric insulators, some of these artificial pollution layers were applied to test specimens, which were then covered and stored under well-defined conditions. After a certain transfer time, the polluted surface indeed showed the expected effect of hydrophobicity transfer (see Fig. 2). More work will be necessary to develop a way to ensure reproducible application of the pollution layer, especially considering that materials may have different initial hydrophobicity levels.

Summary

CIGRE TB 442 describes test methods to better quantify hydrophobicity. This is important since this much-valued property of an insulator can be quite different in terms of retention, recovery and transfer to the pollution layer.

Care was taken to develop test methods which are relatively easy and which can be performed without sophisticated equipment. Reproducibility of these test methods was then confirmed by international Round Robin tests.

[inline_ad_block]