To ensure optimal performance, outdoor electrical insulation must have a design that is adequate and suitable for the service conditions applicable. Environmental factors such as amount of rainfall, frequency of atmospheric discharges, pollution level, etc. are therefore all important considerations in insulator selection.

Peru has 3 regions with much different climatic and geographical environments. The industrialized coast, with its large agro-business, is characterized by salt pollution, high humidity and scarce rainfall and the main challenge is reducing high maintenance costs related to frequent cleaning of insulators. In the Andes, by contrast, transmission lines operate at altitudes up to 4500 m with considerable rainfall and soils with resistivity greater than 5000 ohms-meter. The main problem for insulators in this area relates to atmospheric discharges as well as high solar radiation. Compared to the coast, this region has almost no need for preventive maintenance due to its low contamination and most maintenance applied to insulators is corrective due to sudden deterioration. A third distinct service environment is the Amazon, where dense vegetation, heavy rain and high isokeraunic levels are all relevant factors in maintenance. The main problems for insulators operating in this region relate to atmospheric discharges and biological growths on insulator surfaces.

This edited contribution to INMR by Samuel Arturo Asto Soto of Red de Energía del Perú (REP) in Lima as well as D. A. Da Silva and R. A. S. Juliani of the Military Engineering Institute in Rio de Janeiro, Brazil describes aspects related to performance of polymeric insulators across these three distinct environments. It also reviews the most suitable replacement and maintenance strategies that were developed based on experience across these service areas.

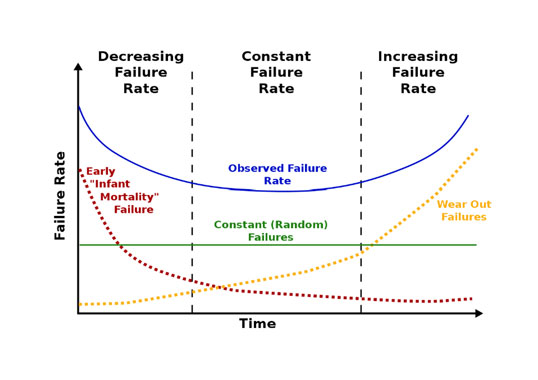

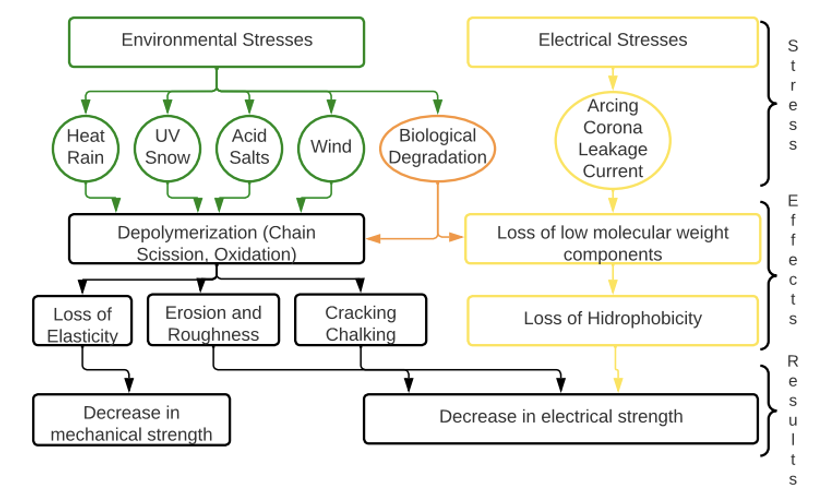

Insulators are essential to guarantee the safe operation of high voltage power systems and to increase reliability of transmission lines. Ageing of insulators can greatly impact reliability and as much as 50% of all maintenance costs for power networks is due to failures involving insulators. Although polymeric insulators offer stable performance even in the worst environmental conditions, premature deterioration can be especially problematic when they are put into service in areas with accelerated ageing factors such as heavy pollution combined with frequent moisture, high ultraviolet radiation, dust, heat and atmospheric pressure. Fig. 1 depicts a schematic of the principal ageing factors relevant for polymeric type insulators under different environmental stresses

Peru is among the places worldwide with the highest recorded values of pollution, UV radiation and lightning strikes. As such, some types of insulators have proven more suitable to be installed in different environments based on their relevant electrical and mechanical characteristics.

Climatic Conditions & Transmission Line Characteristics

Peru has three geographic zones, which are much different from each other and present different kinds of ageing to insulators. The coastline features high saline corrosion and is also the most industrially developed part of the country. Due to limited rainfall, pollution levels can become high. The mountains of the Andes, while far from the problems of the industrialized coast, nonetheless have a high UV index and lightning probability – both of which are important ageing factors. Finally, the eastern portion of the country is a tropical forest. Despite lack of pollution and marine corrosion, this region experiences high pluviometric indices and solar radiation, which are potentially detrimental to insulators. In addition to these climatic conditions, biological factors also have to be considered since this environment is particularly suitable for growth of many kinds of fungi and lichen on insulator surfaces.

Each of these distinct zones presents different challenges for selection and installation of insulators on transmission lines and there is no single universal solution for insulators. By way of comparison, while some 99 percent of insulators installed in Korea are ceramic type, each transmission line in Peru requires careful consideration of the region and conditions where insulators will be installed.

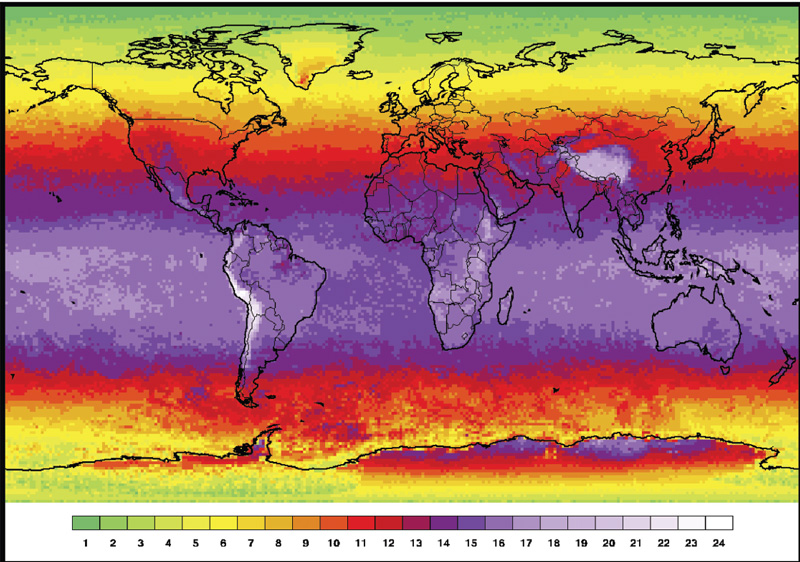

At the same time, Peru offers an excellent example of a place where there are differing environmental ageing factors that can impact long-term performance of polymeric insulators. For example, there are some very dry areas and even deserts but also areas with an extremely humid and tropical climate. The coastal area is defined as a narrow band of desert stretching almost 3000 km and sandwiched between the high mountains of the Andes and the Pacific Ocean. This area represents 11% of Peru (shown in yellow in Fig. 2).

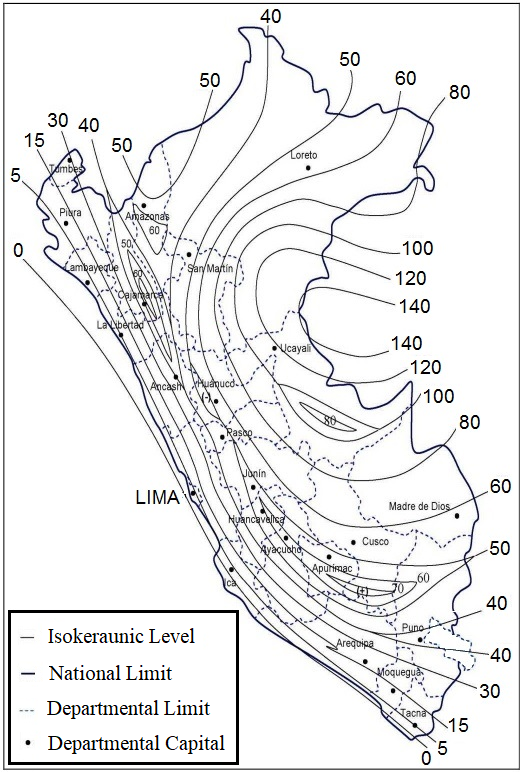

Due to their length, continuity and height, the Andes significantly disrupt local atmospheric circulation resulting in sharply contrasting climate conditions along the eastern and western slopes as well as adjacent lowlands. Between 5°S and 30°S (tropical and subtropical latitudes), relatively cold and arid conditions prevail along the Pacific coast extending to the western slopes of the Andes while warm, moist, and rainy conditions prevail over the eastern slopes. The Peruvian coast, located mostly between 5°S and 18°S, has a dominant southerly wind component that carries particles from the sea. The Andes work as a natural barrier to rain, which means the rainy season is scarce, as seen in Fig. 3 by the low isokeraunic level. Without natural washing, a salt deposit layer quickly forms on the surface insulators operating on transmission lines in this area.

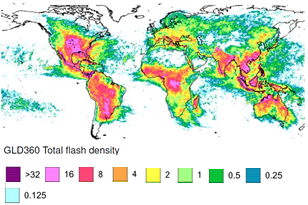

Moreover, comparing Peru with other countries located at the same latitude, the level of lightning discharges is considerable higher (see Fig. 4).

Another environmental factor that can accelerate ageing of insulators is solar radiation and Peru presents one of the highest UV levels anywhere (as seen in Fig. 5 which shows that the Altiplano region of South America has the highest UVI values in the world).

Case Scenarios for Transmission Lines in Peru

220 kV Coastal Line

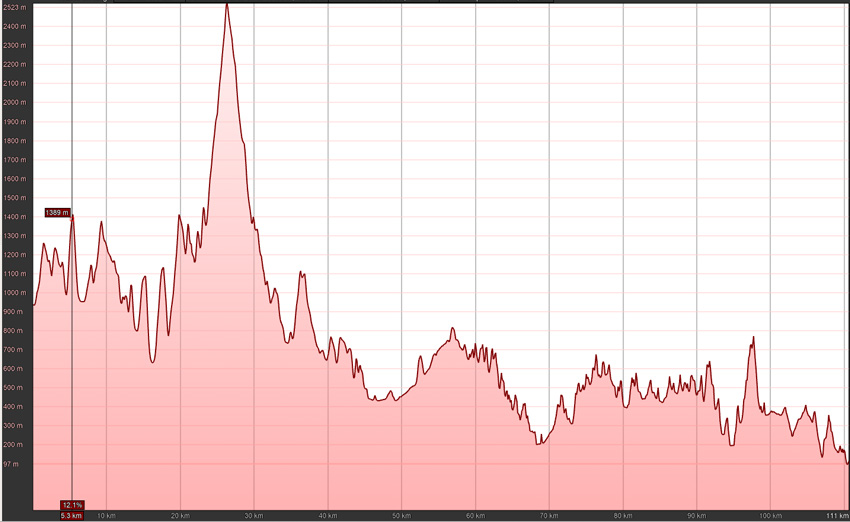

The first Peruvian transmission line analyzed has been in operation since 2009 and is located on the central coast. 220 kV L-2109 Platanal-Chilca runs through Lima State and connects the El Platanal Hydroelectric Power Plant with the Chilca Substation. Line length is 106.75 km with 190 towers of galvanized steel and 358 MVA of nominal power. Fig. 6 depicts its path, beginning 5 km from the sea and moving about 60 km inland.

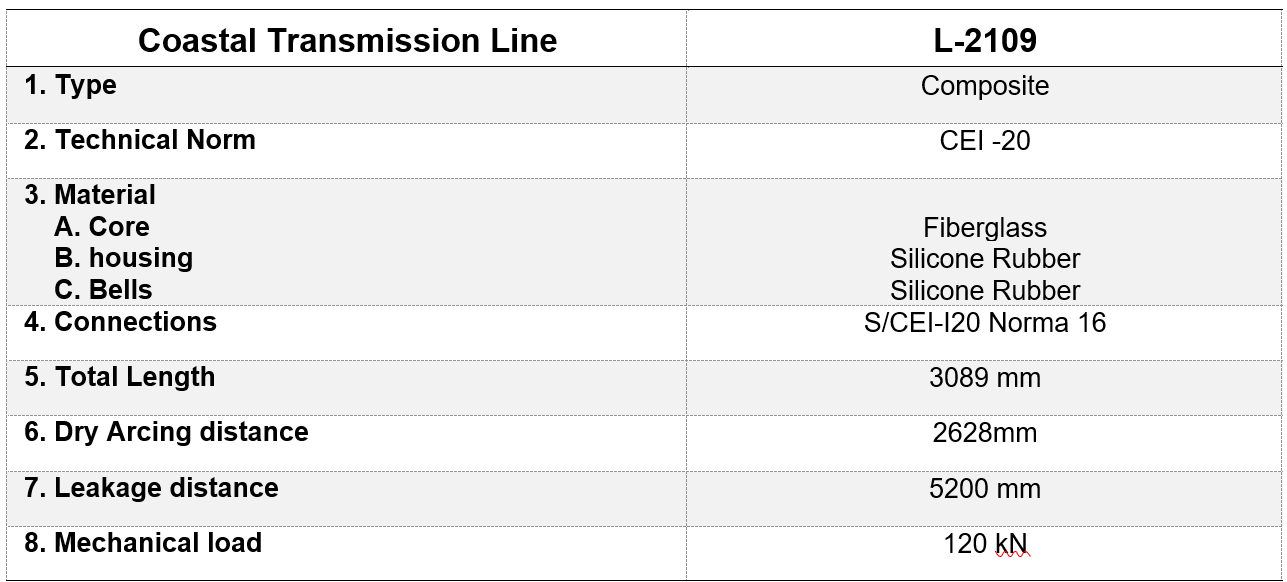

Line L-2109 uses polymeric insulators over its entire length, with a population of 711 insulators installed since 2009. The technical characteristics of these insulators are shown in Table 1. Some 111 of the 190 towers of this line are situated below 500 m altitude and this is an important consideration when analyzing impact of UV radiation on insulator ageing and the performance, i.e. the higher the altitude, the greater the possible impact.

Due to the major part of this line being at lower altitudes, UV is not the main stress factor affecting possible rate of insulator ageing. Rather, the main problem comes from the high pollution and coastal salinity, acting together with heat from solar radiation on insulator surfaces. Insulators are exposed to high thermal amplitudes combined with low pluviometric levels, similar to deserts.

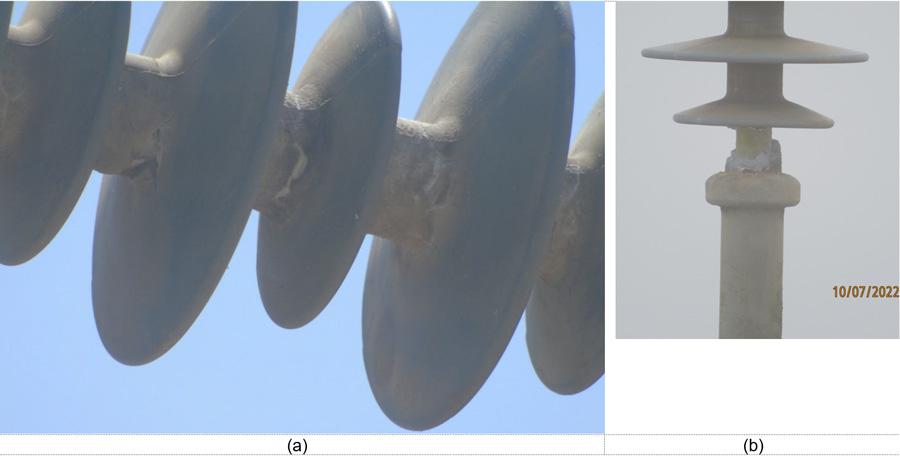

While most coastal transmission lines constructed these days in Peru use glass insulators, L-2109 was designed and constructed in 2005 when there was still no experience with behavior of composite insulators in this region. Unfortunately, at least 17 Peruvian lines experienced unexpected problems with composite insulators due to mechanical fracture of the core after less than 10 years in service. Fig. 7 shows the typical pattern of deterioration of composite insulators installed at line L-2109.

220 kV Mountain Transmission Line

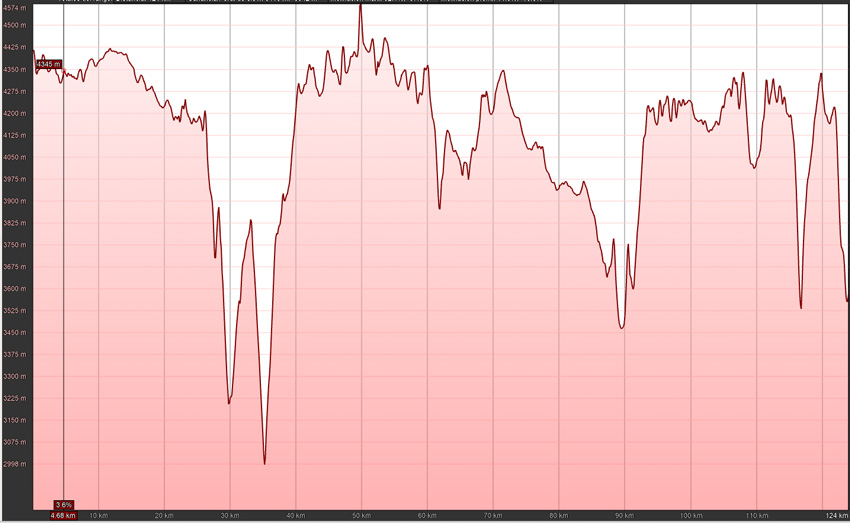

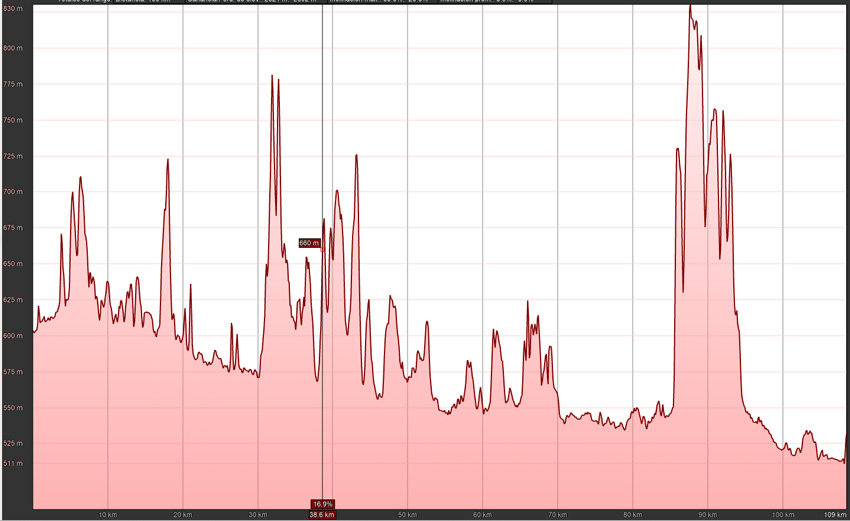

A second case history analyzes performance of composite insulators installed on the 220 kV Paragsha-Vizcarra line located in a mountainous area crossing the states of Cerro de Pasco, Ancash and Huánuco. This line, in service since 2002, runs 121.14 km and is comprised of 287 towers of galvanized steel and nominal power of 250 MVA. The line’s altitude varies between 3260 m and 4570 m with about 76% of the towers located higher than 4000 m (see Fig. 8).

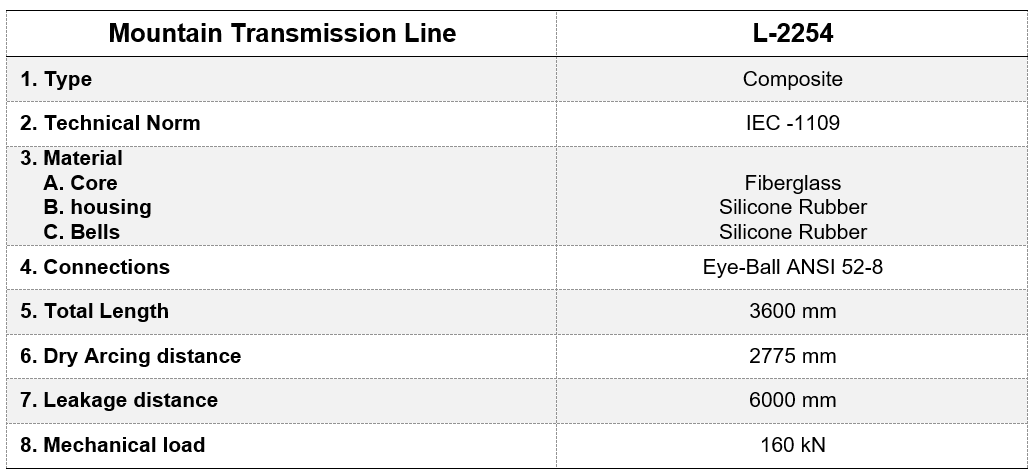

A total of 1115 polymeric insulators are in service on this line and Table 2 describes their technical characteristics.

Since most towers are located at high altitude, these insulators have been exposed to strong UV radiation, intense rainfall and high isokeraunic levels. However, this line is far from urban areas and from the sea, resulting in low levels of pollution and salinity. Therefore, the main factors that typically have caused the flashovers experienced in coastal areas play no role in this environment.

138 kV Forest Transmission Line

A third environment in which composite insulators have been applied in Peru is related to the rainforest. The 138 kV L-1124 transmission line connects Aucayacu-Tocache and crosses the states of Huánuco and San Martin, as seen in Fig. 9. The maximum altitude of this 107.76 km line is 800 m and it has been in service since 2000, with 305 towers of galvanized steel and nominal power of 45 MVA. The line passes through mostly unpopulated areas having plenty of wildlife. In this case, the major factors related to risk of insulator ageing are interaction with animals as well as growth of lichen and fungi on surfaces.

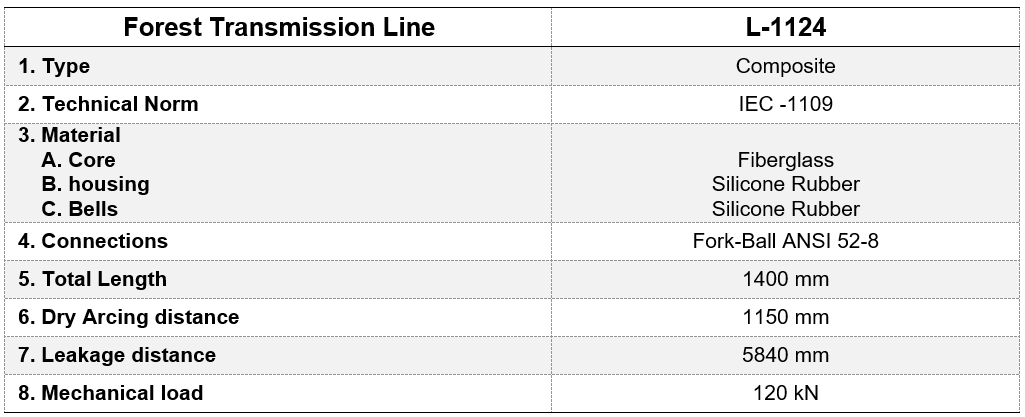

There are 1112 polymeric insulators installed across its route and due to the longtime of operation of this line, many of these were replaced in 2018 meaning that they have been in operation for less time than the insulators on other transmission lines. Table 3 summarizes the technical characteristics of these insulators.

The entire line is situated below 800 m and, being far from urban centers and the sea, salinity and pollution are only minor factors in any insulator ageing. Nevertheless, this line is exposed to intense and constant rain, biological attack, lightning and high levels of UV radiation. The forest environment does not present risk of partial discharges since insulators are constantly being washed by the rain. Although polymeric insulators can be highly suitable for this kind of ecosystem, the presence of fungi and lichen poses a risk to their electrical performance and can increase risk of possible degradation.

Insulator Performance Across These Environments

Performance of polymeric insulators installed on transmission lines in Peru over the last 50 years has been diverse. Based on operational factors such as ambient climatic conditions, nominal power and voltage of lines and time in service, their lifespan has varied as have rate of failures and need for corrective maintenance. The following reviews what has occurred along the transmission lines described above to compare relative performance across Peru’s different geo-climatic conditions.

220 kV Coastal Transmission Line

Transmission line L-2109 goes through two different environments, with about 58% of its length in the Andes while the remainder lies in the coastal area. Some insulators on this line needed replacement due to advanced deterioration, especially in the coastal section (see Fig. 10). Currently, maintenance needs are frequent and tend to take place every 2 years. Considering this and the fact that these insulators are already 14 years old, it can be assumed that they are nearing the end of their service life and different maintenance strategies will need to be applied.

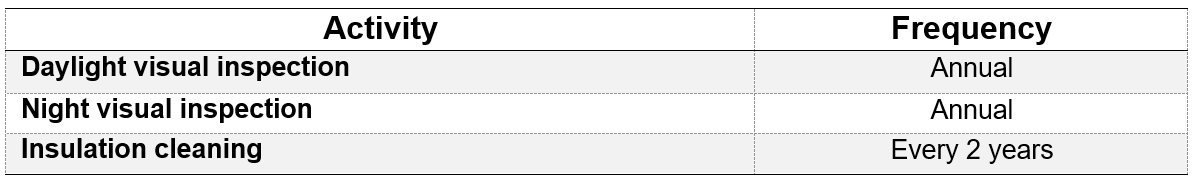

It should be noted that in the early 2000s, there was an outbreak of mechanical fractures of polymeric insulators installed in coastal areas of Peru. This led to implementation of a maintenance strategy that focused on identifying signs of insulator degradation in a timely manner before this could lead to a complete rupture (see Table 4).

This preventative maintenance strategy, aimed at ensuring continuous operation and high reliability, consists of measures such as regular inspection and cleaning of the insulators. Hand cleaning, as shown in Fig. 11, while a slow process has proven helpful in removing surface salinity and the pollution layer on insulators. The result of this maintenance has been continuous operation of the lines and no service interruptions due to insulation breakage has occurred since implementation of this strategy started in in 2010. Indeed, this maintenance strategy has proven highly successful since the failure database between 2010 and 2023 shows only one record of failure on this line caused by an external factor.

It is worth noting that there are other coastal lines in Peru with far more aggressive pollution conditions than affecting L-2109 and where application of polymeric housed insulators is not permitted. In these cases, only RTV coated glass is used. In 2024, new polymeric insulators will be installed to replace all insulators along this transmission line.

L-2254 Mountain Transmission Line

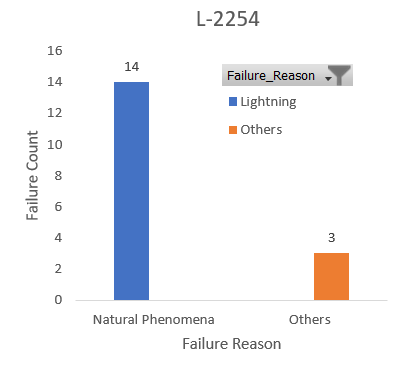

Line L-2254 runs in the Andes at altitudes of around 4000 m, meaning that insulators are exposed to high UV radiation and frequent atmospheric discharges. Protection of this line is therefore based on application of transmission line arresters (TLAs) as well as two shielding cables along its entire length. A total of 169 (67.6%) of the line’s 250 structures operate with TLAs.

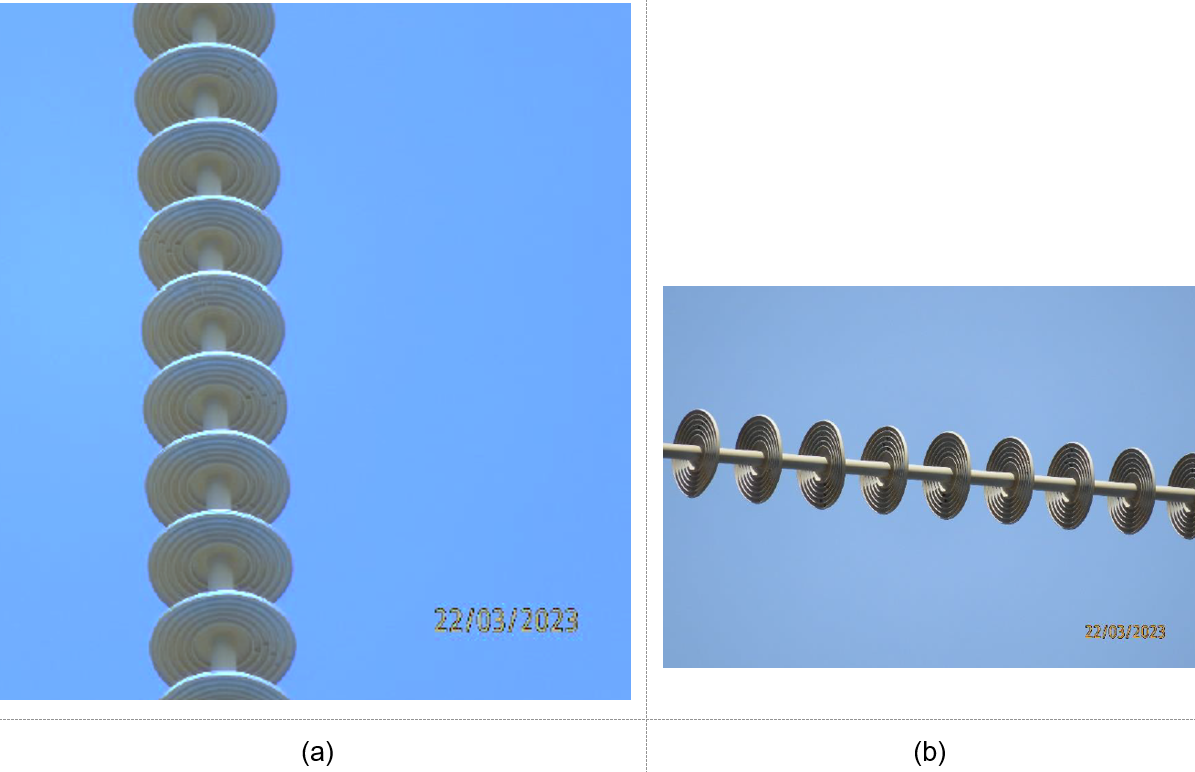

Fig. 12 indicates that the main reason for failures on this line are atmospheric discharges. No failures of insulation were observed and this is due to the fact that the area around this line has favorable conditions for natural cleaning of insulators, thereby avoiding build-up of salinity and other contaminants. After 21 years in service, most insulators appear as shown in Fig. 13, with few if no signs of deterioration.

Nonetheless, between July and August 2023 all insulators on this line were replaced – not because of high failure rate but rather because the original estimated life expectancy for this zone (i.e. between 18 and 20 years) had been exceeded. Owing to frequent rainfall, maintenance activities for insulators in this zone are limited to visual and annual thermographic inspections. Polymeric insulators have demonstrated good performance in areas located in the Andean Zone and field experience confirms that the real lifespan of these insulators is higher than originally foreseen.

L-1124 Forest Transmission Line

The insulators originally projected for L-1124 were made with liquid silicone rubber (LSR) housings. These insulators, installed in 2000, have shown many failures since their fifth year of operation (see Fig. 14). Therefore, many were replaced by high temperature vulcanizing (HTV) silicone insulators equipped with equipotential (grading) rings to avoid occurrence of discharges on their surface.

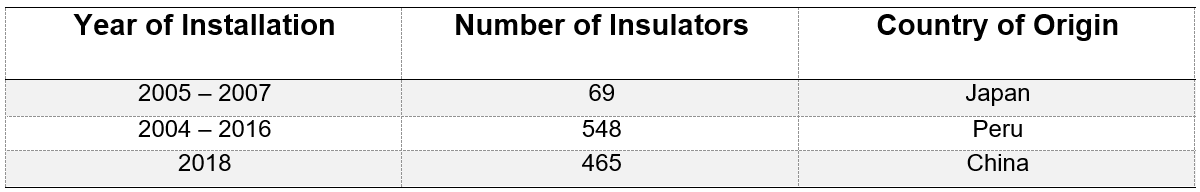

In fact, by 2018 all LSR type insulators initially installed on the line had been replaced, in a process which prioritized those showing most evidence of deterioration or signs of impending failure. Nowadays, all insulators installed on this line are made only with HTV silicone housing material. Table 5 shows the source and number of these insulators.

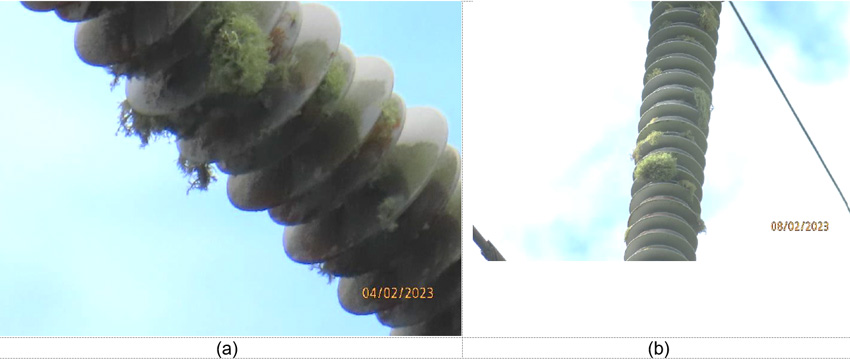

One factor potentially influencing performance of insulators on L-1124 relates to biological contamination since the tropical and humid climate favors growth of species such as fungus and lichen (see Fig. 15).

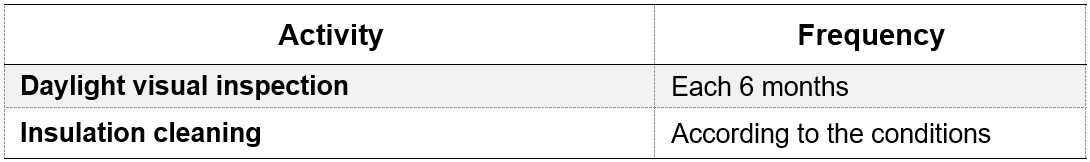

As with coastal transmission line L-2109, a new maintenance strategy has been developed to minimize risk of insulation failures on this transmission line. This maintenance plan, shown in Table 6, involves daylight inspection twice yearly combined with cleaning affected insulators, depending on findings.

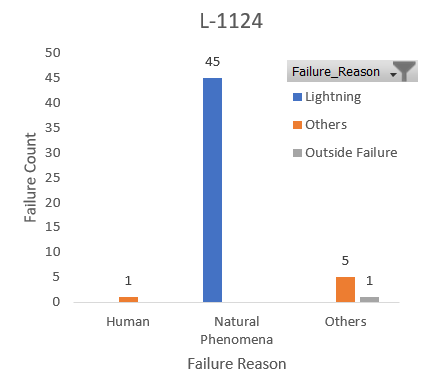

In summary, performance of polymeric insulators in this geographical area has generally met original estimates since initial failures were due to an inadequate housing material rather than to improper design. Once corrected, insulators are no longer the main cause of failures along this line. In fact, as shown in Fig. 16, the main cause of failures on L-1124 are lightning and other natural phenomena.

Although preventive maintenance must still be taken to ensure these insulators perform properly, there are insulators along it that already have 18 years in service, close to their originally estimated lifespan.

Conclusions

Application of polymeric insulators across the different geo-climatic conditions in Peru has allowed REP to evaluate the most suitable type of insulator for each area, offering good performance at low cost and with low risk.

In coastal zones, located up to 30 km from the seacoast, it has been deemed preferable to avoid using polymeric insulators or to consider their replacement with a short lifespan – usually 4 years in service. They are only deemed acceptable for coastal areas when there are additional factors, for example high rate of breakage of glass insulators due to excess electric field values combined with pollution. In mountainous and jungle areas with low levels of pollution and frequent rainfall, use of polymeric insulators is considered highly suitable. Although there are concerns about their performance under atmospheric discharges, there are no recent cases of failures due to such discharges and overall experience has been positive. In fact, recorded failures were due principally to inadequate housing material and design given the level of solar radiation, electric field and atmospheric discharges in a jungle environment.

In short, it is important that transmission line projects in the different geo-climatic zones considered above follow the following recommendations:

1. Leakage distance suitable for extra high pollution (e.g. coastal areas);

2. Polymeric material that resists high levels of radiation and high currents from atmospheric discharges;

3. Fiberglass cores and seals that can withstand high electromechanical demands.

Based on service experience with composite insulators in Peru, the lifespan of the insulators installed on transmission lines across its different geo-climatic conditions can be estimated as:

Coastal Zones: Lifespan between 4 and 12 years.

Jungle & Mountain Areas: Lifespan between 15 and 20 years.

The operating time of the transmission lines discussed above has allowed engineers at REP to understand the real performance of this type of insulator in South America, with its unique climatic characteristics. It is recommended that current standards be reviewed to include the levels of contamination, solar radiation and lightning flash density that occur in South America and to consider these in the classification and design of insulators. In addition, development and testing of polymeric insulators for application in coastal areas should be undertaken to offer designs that equal or exceed the current performance of RTV-coated glass.

BIBLIOGRAPHY

[1] M. Amin and M. Salman, “Aging of polymeric insulators (an overview),” 2006. [Online]. Available: http://waterheatertimer.org/Names-of-parts-on-electric-pole.html

[2] W. K. Lee, I. H. Choi, K. Y. Shin, K. C. Hwang, and S. W. Han, “Accelerating Aging of Transmission Line Porcelain Suspension Insulators by Autoclaving,” Transactions on Electrical and Electronic Materials, vol. 9, no. 147, 2008.

[3] S. Sanyal et al., “Deterioration of Porcelain Insulators Utilized in Overhead Transmission Lines: A Review,” Transactions on Electrical and Electronic Materials, vol. 21, no. 1. Korean Institute of Electrical and Electronic Material Engineers, pp. 16–21, Feb. 01, 2020. doi: 10.1007/s42341-019-00143-5.

[4] R. S. , et al. Gorur, “Utilities share their insulator field experience,” Transmission and Distribution World, vol. 57, no. 4, pp. 17–27, 2005.

[5] I. H. Choi, T. K. Kim, Y. B. Yoon, T. Kim, H. T. T. Nguyen, and J. Yi, “A Study on the Life-Time Assessment Ways and Various Failure Types of 154 kV Porcelain Insulators Installed in South Korea,” Transactions on Electrical and Electronic Materials, vol. 19, no. 3, pp. 188–194, Jun. 2018, doi: 10.1007/s42341-018-0027-7.

[6] P. Cygan and J. R. Laghari, “Models for Insulation Aging under Electrical and Thermal Multistress,” 1990.

[7] M. Akbar, R. Ullah, and S. Alam, “Aging of silicone rubber-based composite insulators under multi-stressed conditions: an overview,” Materials Research Express, vol. 6, no. 10. Institute of Physics Publishing, Sep. 06, 2019. doi: 10.1088/2053-1591/ab3f0d.

[8] CIGRE WG.B269, Coating for improvement of electrical performance of outdoor insulators under pollution conditions, vol. 837. CIGRE Technical Brochures, 2021.

[9] International Electrotechnical Comission, IEC 60587:2022. 2022. Accessed: Aug. 29, 2023. [Online]. Available: https://webstore.iec.ch/publication/61338

[10] International Electrotechnical Comission, “IEC 62217:2012,” 2012. https://webstore.iec.ch/publication/6596 (accessed Aug. 29, 2023).

[11] G. Pirovano, P. G. Omodeo, and A. Pigini, “Assessment of the pollution performance of composite insulators,” ISH, 2013.

[12] J. Woodhouse, “Finding the right mix of costs, risks and performance,” Asset Management Decision-Making, 2001.

[13] “Maps: From Fires and Floods, Peru Sept 2016 – Mar 2017, last accessed: January 28, 2018.,” 2017.

[14] R. D. Garreaud, “The Andes climate and weather,” Adv. Geosci, vol. 22, pp. 3–11, 2009.

[15] J. Yanque, “Mapa Isoceraunico Peru.” 2005.

[16] L. F. Suárez Salas, J. L. Flores Rojas, A. J. Pereira Filho, and H. A. Karam, “Ultraviolet solar radiation in the tropical central Andes (12.0°S),” Photochemical & Photobiological Sciences, vol. 16, no. 6, pp. 954–971, June 2017, doi: 10.1039/C6PP00161K.

[17] F. Zaratti, R. D. Piacentini, H. A. Guillén, S. H. Cabrera, J. Ben Liley, and R. L. McKenzie, “Proposal for a modification of the UVI risk scale,” Photochemical & Photobiological Sciences, vol. 13, no. 7, pp. 980–985, Jun. 2014, doi: 10.1039/C4PP00006D.

[18] R. Cordero et al., “The world’s highest levels of surface UV,” Photochem. Photobiol. Sci., vol. 13, pp. 70–81, 2014.

[19] S. A. A. Soto, “Performance of RTV silicone rubber pre-coated toughened glass insulators in zones of high salt contamination: Peruvian experience,” in INMR World Congress, D. A. Da Silva, Ed., Tucson, 2019.

[20] S. A. A. Soto, “Composite Isolators Performance in Aggressive Environment: Comparison vs Coated Glass Isolators,” in INMR World Congress, Berlin, 2022.

[21] I. M. Loardo, “Experiencia en el uso de aisladores poliméricos en zonas de alta contaminación,” Revista CIER, vol. 57, 2010.