Electric energy has become pervasive and public expectations for availability, reliability and quality have being rising for decades. Yet in recent years, there have been a succession of catastrophes across the globe linked to extreme climatic events that also severely cripple power systems in the areas affected.

Against this backdrop, T&D expert, Alberto Pigini, offered insight into some issues that will need to be addressed.

The real challenge in meeting forecasts for substantial growth in electric energy demand has been to develop all the required new generation, transmission and distribution capacity at the investment, once estimated at some US$ 17 trillion. At the same time, it would be necessary to produce all this additional energy without increasing CO2 emissions which are confirmed as influencing climate change in terms of the comparative incidence of so-called normal versus extreme weather events.

Even if the cause of climate change is still debated in some circles, its existence has long been firmly established. For example, during a past International Forum on Disaster Prevention and Mitigation, a five-fold increase in incidence of catastrophic events was reported between 1970 and 2005 alone. This trend has continued and, if anything, even accelerated over the past 20 years.

An electric power system is fragile towards extreme weather threats and bad things are going to happen to power lines and insulators following such phenomena. Indeed, this concept was specifically expressed during a past CIGRE Panel on impact of natural phenomena on operation of power systems. Highly publicized destructive events such as Hurricanes Katrina and Maria in the United States are already well known. But lesser-known events have also occurred, in some cases being so extreme that there is no memory of similar conditions over two or three previous generations.

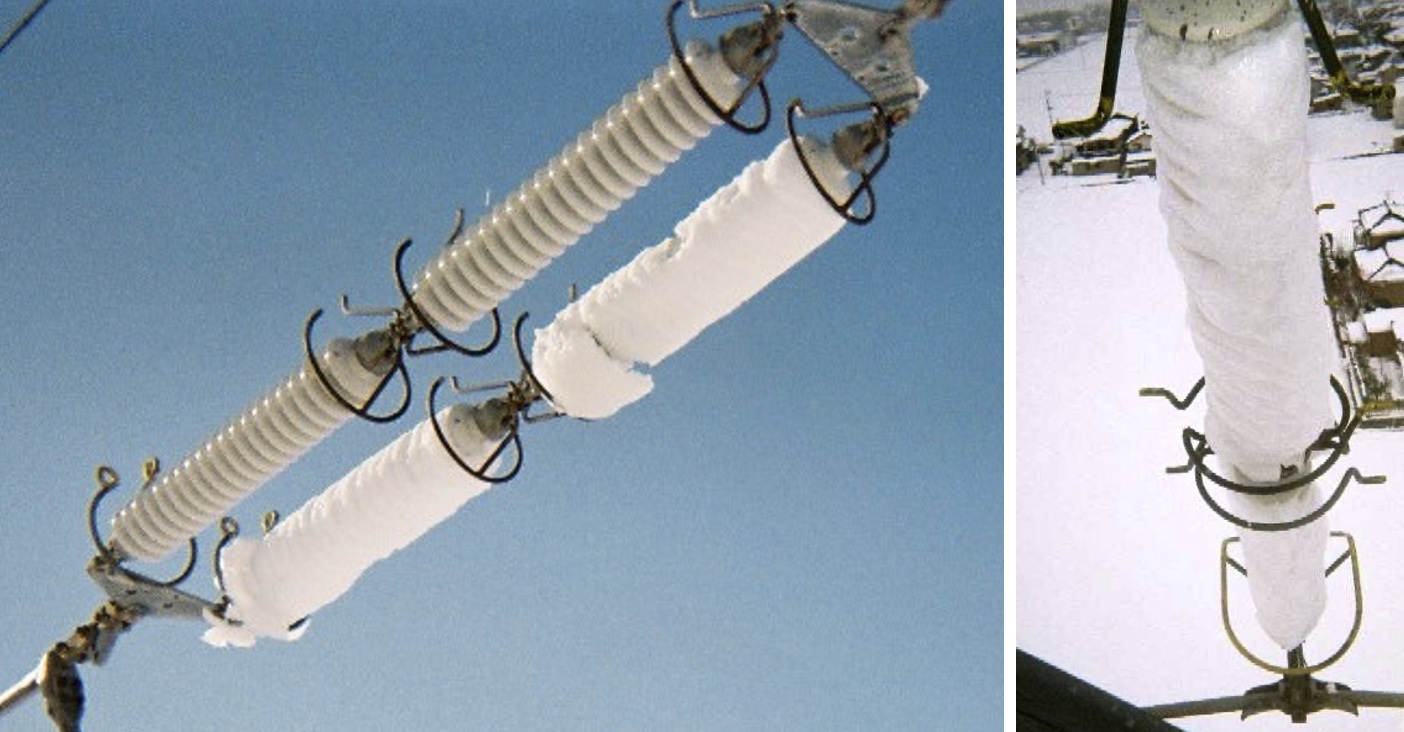

Examples during one decade alone, 1995 to 2005 included: the ice storm in Canada with 3100 towers and 120 transmission lines damaged (January 1998); the hurricane and extreme heat wave in France (December 1999 and summer 2003 respectively); the Gudrum extreme storm and hurricane in Sweden (January 2005), intense snow falls with ice and snow loads some 15 times higher than standard requirements in Germany (November 2005); severe wet saline snow on lines and insulators in Japan resulting in multiple pollution flashovers (December 2005); extremely severe and extended dry periods accompanied by several fires along lines, together causing exceptional contamination accumulation on insulators and multiple flashovers in South Africa (February 2006); a once-in-50 year severe snow storm in New Zealand (June 2006).

In all cases, these ‘natural’ phenomena resulted in loss of electricity supply to numerous customers accompanied by varying degrees of damage to T&D assets. Depending on severity of this damage, the process of restoring power varied from a few hours to several weeks. In some cases, years were required to recover, as during destruction of 80% of the power grid in Puerto Rico due to Hurricane Maria in September 2017. All this should be considered against the expectation of most consumers who now see electric energy as indispensable.

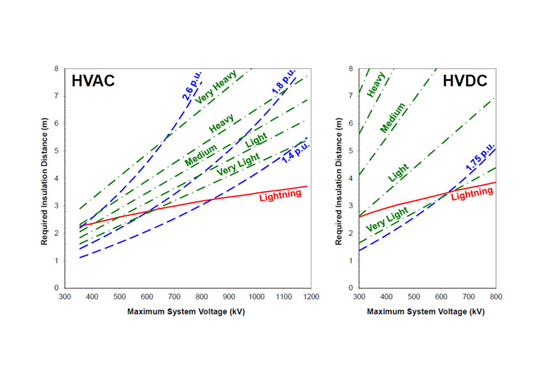

Many questions arise in connection with such events: Where do the responsibilities and liabilities lie? Are weather assumptions behind design still valid and are present standards even still adequate? Should the expected evolution of weather parameters be taken into account in design and, if so, should design be made for the most extreme conditions, whatever these might be? Should systems be hardened or should utilities just prepare to recover more efficiently whenever disasters occur? Is current preparedness adequate and should stocks of spare equipment and components such as insulators be increased?

Disaster is a harsh teacher. Integrated solutions are probably required which combine reinforcement of the power grid with better and more efficient emergency planning. Of course, while perhaps no level of reinforcement could resist catastrophic conditions such as a Class 5 Hurricane with wind gusts up to 346 km/h, in other cases reinforcement could well be a solution.

And what about reinforcing insulation? One of the aspects here would be to reinforce their electrical withstand response to extreme and unforeseeable conditions. Examples of reinforcement to insulation after disasters include re-insulation with silicone rubber insulators in South Africa as well as replacement of standard insulators with superior ‘tougher’ designs under conditions of ice and snow accumulation in Japan.

There are several foreseeable insulation reinforcement options and these include:

• more efficient pollution monitoring, to forecast and avert build-up of critical conditions (e.g. by insulator washing);

• dynamic pollution mapping, by integrating pollution monitoring, weather parameters monitoring and advanced modelling;

• selecting the most appropriate insulators for each specific service environment, e.g. type of pollution, incidence of ice and snow, etc.;

• taking advantage of the full benefit of the hydrophobicity of composite and RTV-coated glass and porcelain insulators.