Silicones in their cross-linked elastomeric form are the rubber materials found in most high voltage insulators and also used as housings for arresters and bushings, among other electrical components. It is therefore worthwhile reviewing the chemistry of this important family of polymers.

CLICK TO ENLARGE

The proper name for silicones is ‘siloxanes’, which consist of a silicon (not to be confused with silicone) and oxygen backbone that can be cross-linked by different chemical reactions. They can also be modified such that their polymeric structure remains non-reactive at typical application temperatures. These modified products, also classified as polydimethylsiloxanes (PDMS), demonstrate how versatile this group of materials can be across a broad variety of applications for medium as well as high voltage insulation.

The electrical industry already relies greatly on a number of non-reactive PDMS materials. Among these, for example, are low viscosity silicone fluids. These fully synthetic fluids are stable against heat and oxidation and frequently used in transformers, electro-magnetic devices and capacitors. The liquid insulating material has low loss factor and provides a high fire and flashpoint. These advantages combine with other benefits such as comparatively low heat of combustion and low smoke density.

The chemistry of silicones allows chain length of siloxanes to be controlled so that it becomes possible to also serve the market with a range of tailor-made fluids. These feature different viscosities and also chemical modification of their side chains. In the power industry, such products are used as thermally and oxidation stable fillers that not only offer excellent electrical insulation properties but also provide other benefits, including low dielectric loss factor. Moreover, depending on their viscosity and chemical modification, they will allow only very low migration rate into solid insulating materials.

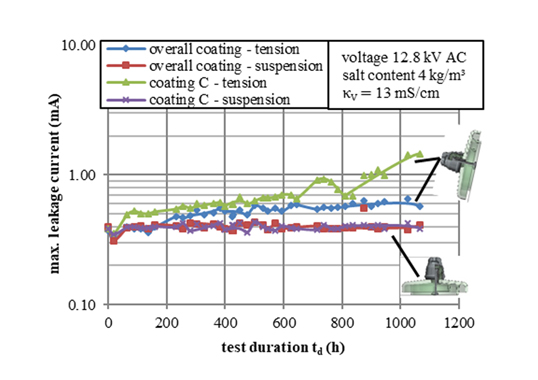

Basically, it is but a small step from these types of fluids to their thickened modifications – known as pastes. Silicone pastes are widely used as sliding aids in the cable accessories business. Depending on design and application of the insulating part, the paste is intended to remain where initially applied or to disappear, by migrating completely or partially into other insulating materials. Combining suitable thickening and filling materials allows such pastes to be modified to satisfy whatever the expected function. The first application of silicone pastes in the electrical industry actually goes back to the 1950s. At the time, porcelain insulators were ‘siliconized’ with the help of thickened silicone oils to achieve a water repellent (hydrophobic) surface and increased insulation performance. Nowadays, this application has been replaced by RTV silicone coatings.

Dr. Jens Lambrecht

Wacker Chemie

[inline_ad_block]