Performance of glass and porcelain insulators on overhead transmission lines and at outdoor substations is a key factor determining reliability of power systems. Under natural service conditions, insulators must be designed to withstand assigned voltage and occasional overvoltage as well as all environmental electrical and mechanical constraints, including winds, lightning and especially impact of contamination. In this regard, the Gulf Cooperation Council Interconnection Authority (GCCIA) in the Kingdom of Saudi Arabia (KSA) continuously evaluates performance of its system with particular focus on polluted insulators which, when wetted, can lead successively to heavy superficial discharge activity and in critical cases to flashovers and major power disruptions.

This edited contribution to INMR by Ahmad Al-Thagafi and H. Al-Hamoud of the GCCIA as well as A. Bouchti and M. Naud of Omexom/Cegelec in the KSA as well as Raouf Znaidi of Tunisia presents findings of a recent investigation into performance of coated porcelain and glass cap and pin insulators on the GCCIA network. This work is part of an innovative approach being undertaken for both existing double circuit lines and also for future interconnection projects.

GCCIA Network Characteristics

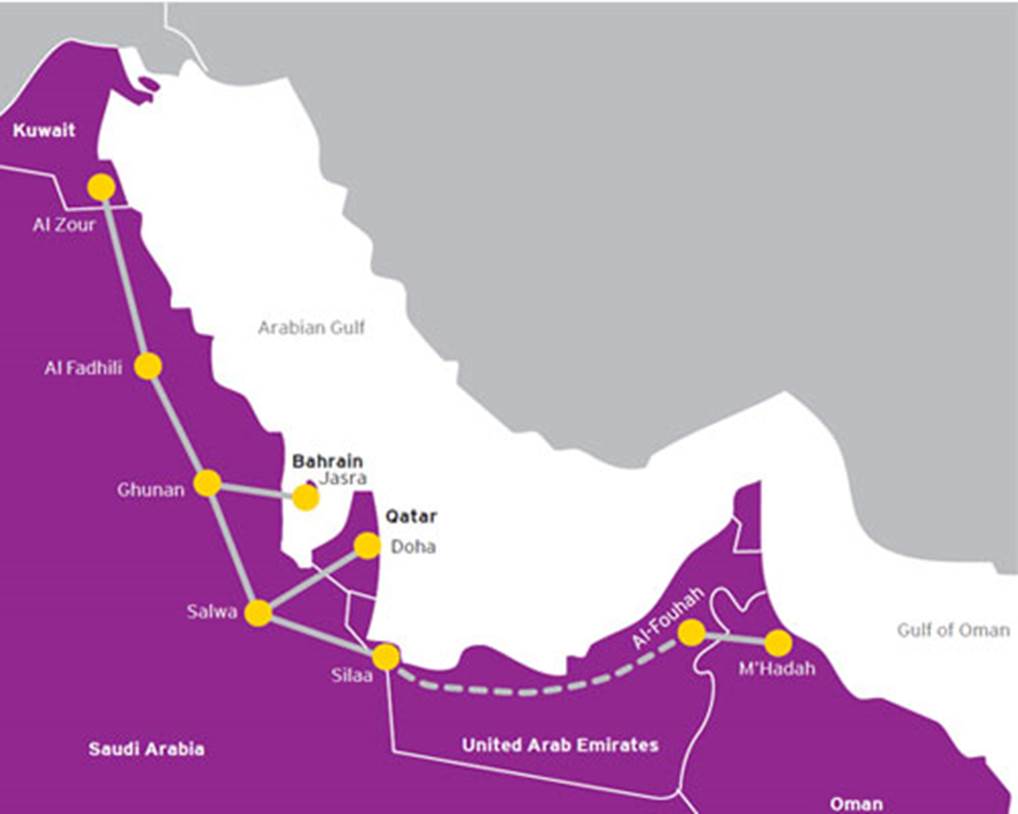

GCCIA’s network is the common backbone of 6 interconnected systems and consists of some 900 km of double-circuit 400 kV 50Hz line extending from Kuwait to KSA and then to Qatar and UAE. There is also a double 400 kV submarine cable linking the Bahrain grid with the GCC Grid (see Fig. 1).

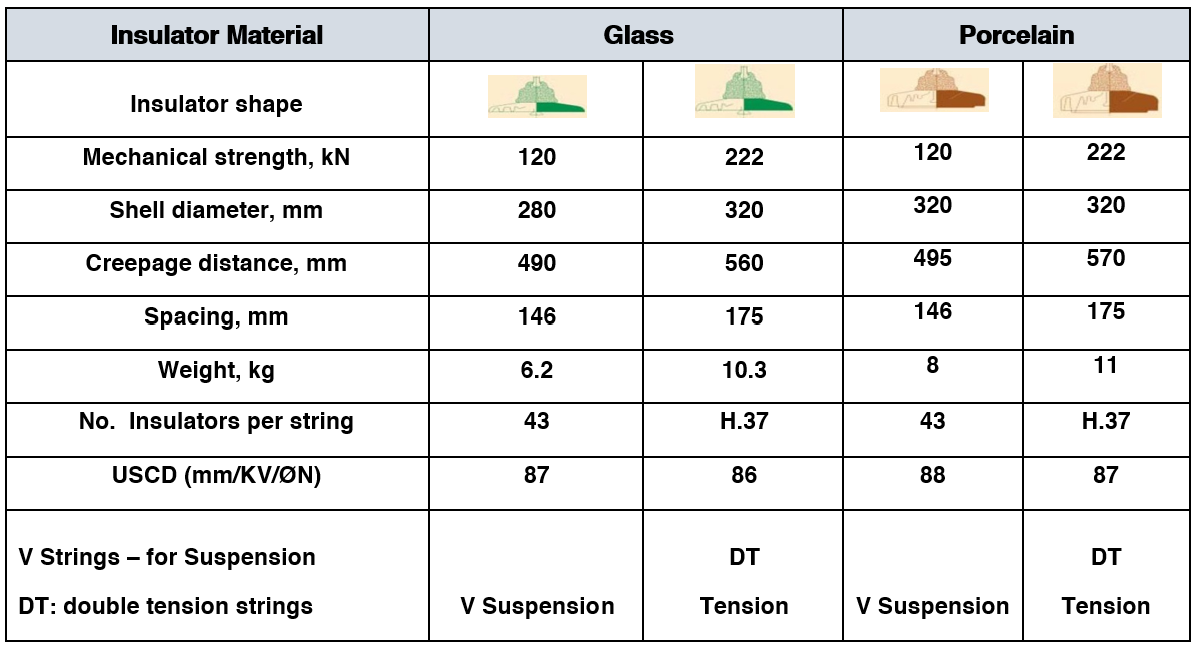

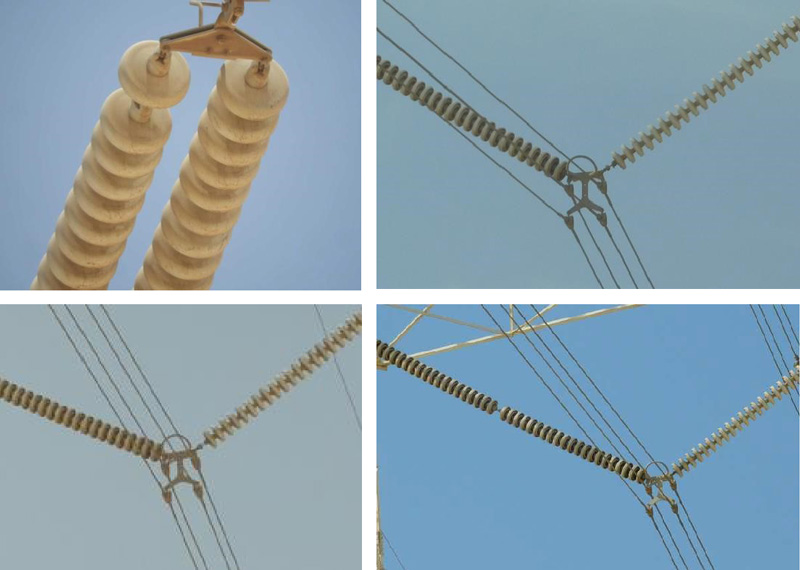

Given the harsh environmental conditions prevailing in eastern KSA, the GCCIA 400 kV system has been over-insulated. Suspension towers are equipped with double anti-pollution strings consisting of 43 RTV coated ceramic (porcelain and glass) insulator discs (120 kN) while 37 coated anti-pollution ceramic insulators discs (222 kN) are used on tension towers (see Table 1). This corresponds to a unified specific creepage distance of up to 87 mm for suspension insulators, according to the latest revision of IEC/TS 60815.

Fig. 2 highlights distribution of porcelain and glass insulators on this overhead network (i.e. blue: glass, red: porcelain).

Maintenance Strategy

Given that the GCCIA system is treated as an emergency support, reliability is the most important criterion determining maintenance strategy. An intensive maintenance plan has therefore been adopted to ensure that this line is always available to support a member state. Given this, the OHL team at the GCCIA has focused year-by-year to close any gaps identified in maintenance in order to remain in a proactive mode to anticipate failures in a timely manner. The maintenance procedures followed in this regard include:

• Ground inspection performed 3 times a year;

• Elevated inspection carried out once every 4 years;

• Walk through inspection of GCCIA right-of-way performed monthly;

• End-to-end and OTDR testing of OPGW and FOC;

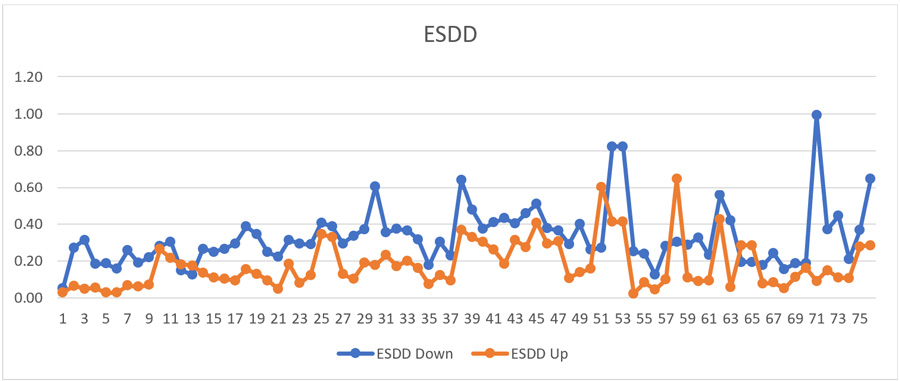

• Measurements of ESDD/NSDD and of coating hydrophobicity performed on insulators removed from two 2 locations on each line;

• Drone inspection;

• Corona camera inspection.

GCCIA System Performance

While the GCCIA has had satisfactory operation since commissioning, it has nonetheless experienced two incidents that led to trips. The first was linked to a wildfire that started under a line, with smoke causing it to trip. This incident was not believed to have been due to failure of the insulation. The affected towers are located near Asfar Lake with much dry grass directly alongside access roads. Since there is no rain over the prolonged dry season, pastures and grass wither, acting as a fuel for this type of fire.

The second incident, also near Asfar Lake, was identified as being due to contamination from heavy bird excrement. Elevated inspection reported that both tower members and insulators were extremely polluted by highly conductive excrement and bird nests.

Insulators with only low levels of pollution were cleaned whereas badly or very badly polluted insulator strings were replaced.

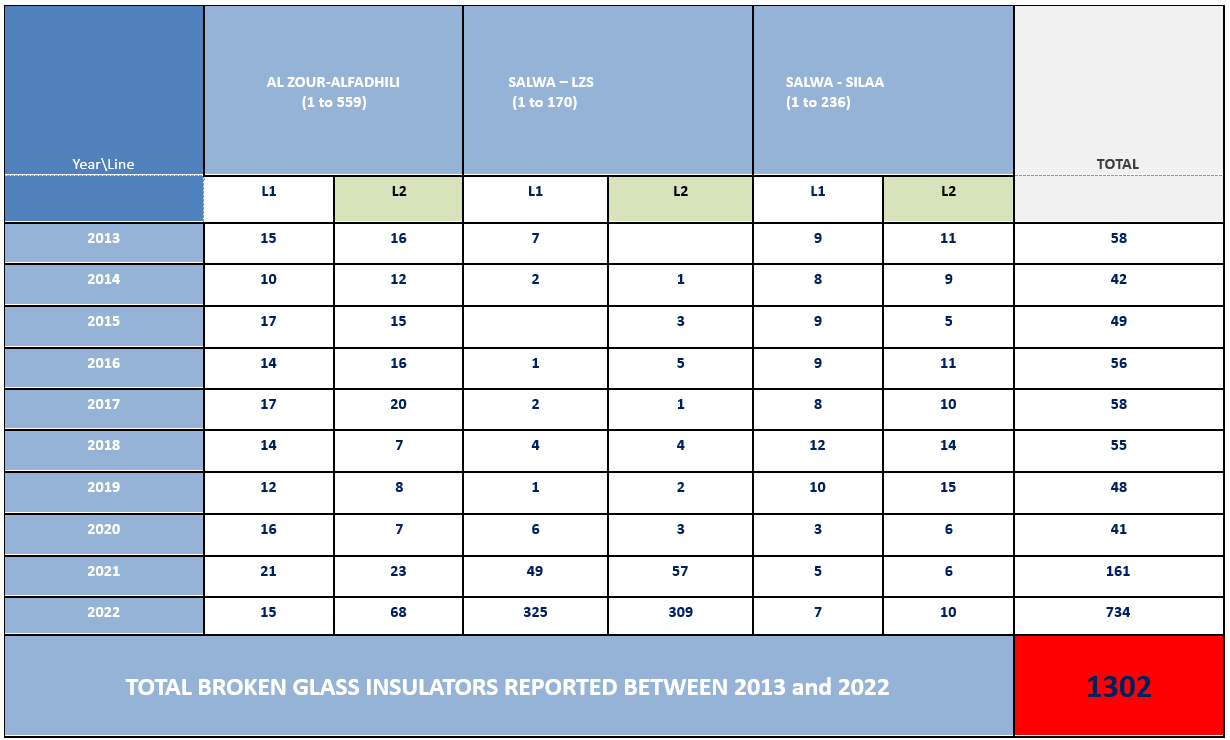

Replacement Rates for Glass & Porcelain Insulators

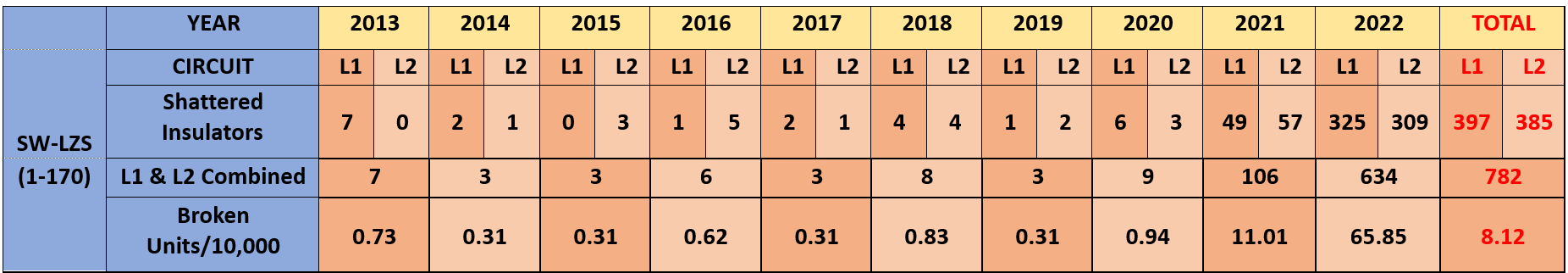

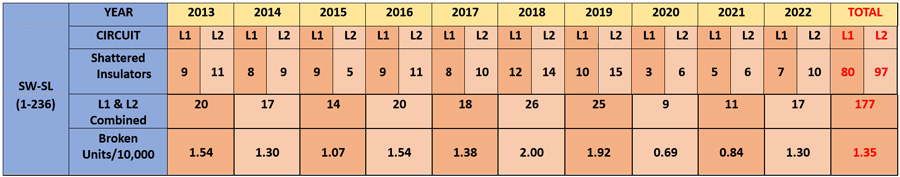

Since the time GCCIA lines were first commissioned in 2009, ground inspections have identified numerous cases of shattered glass insulators. Shattered disks have been reported on the AL-ZOUR-FADHILI (AZ-FD), SALWA-SILAA (SW-SL) and SALWA-LZS (SW-LZS) lines where glass insulators are in service. This motivated the GCCIA to investigate further and a preliminary study looked at number of shattered insulators found up to 2022. Indeed Cigre TB 837 references “an increase of shattering rate of coated glass insulators was observed in very harsh conditions (Saudi Arabia, China, Peru)”.

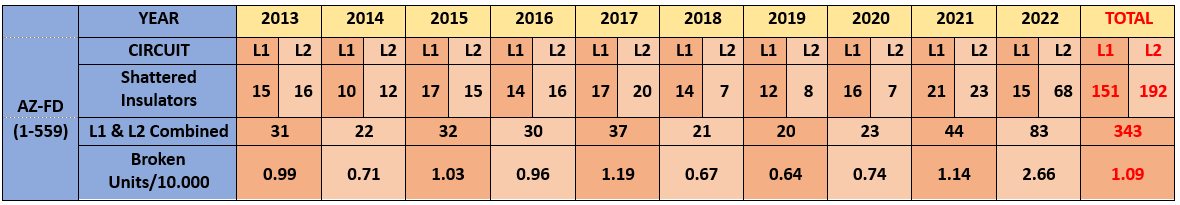

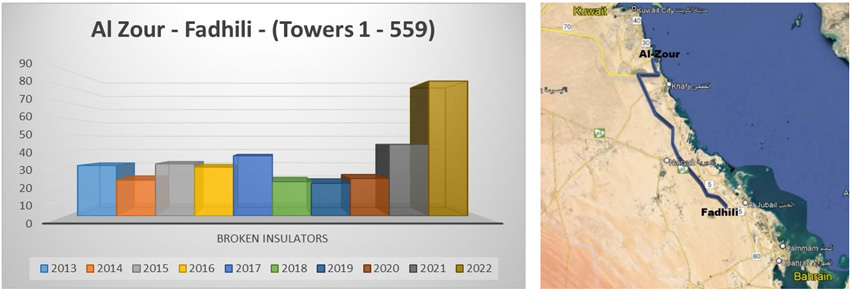

Based on close observation, the following Tables show the situation by line in terms of annual shatter rate per 10,000 units:

In the case of the SALWA-LZS Line, an unexpectedly high number of shattered units were observed over the past two years and the cause is still under investigation. This trend was also observed on the AL-ZOUR-FADHILI line although the increase in shatter rate was less severe (see Table 3).

In 2022, GCCIA experienced the highest number of shattered insulators (634) on the SW-LZS double circuit line equipped with 96,270 coated glass insulators. This translated into a shatter rate of 66/10,000 disks.

Incidence of shattering varied by location of towers and was typically limited to one shattered disk per string.

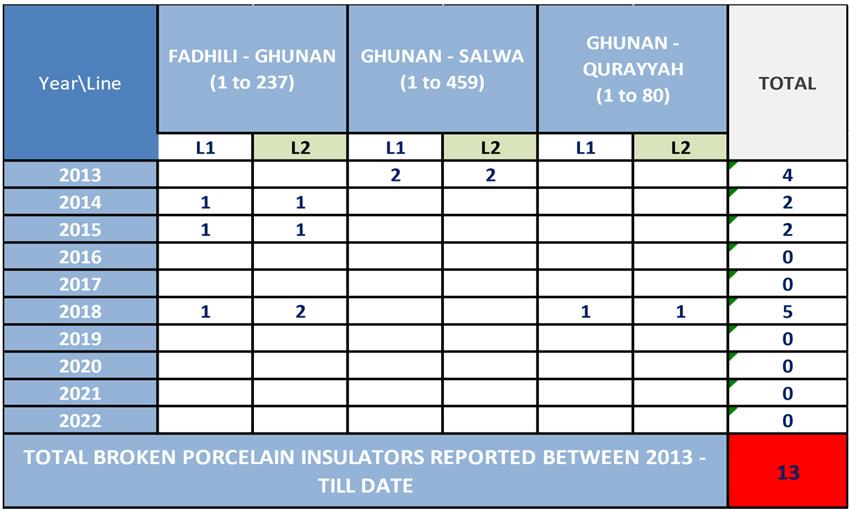

In the case of coated porcelain insulators, the GCCIA has experienced a limited number of incidents (13 in total) where either fully and partly broken porcelain sheds were identified (see Table 6).

Pollution Performance Versus Insulator Shape

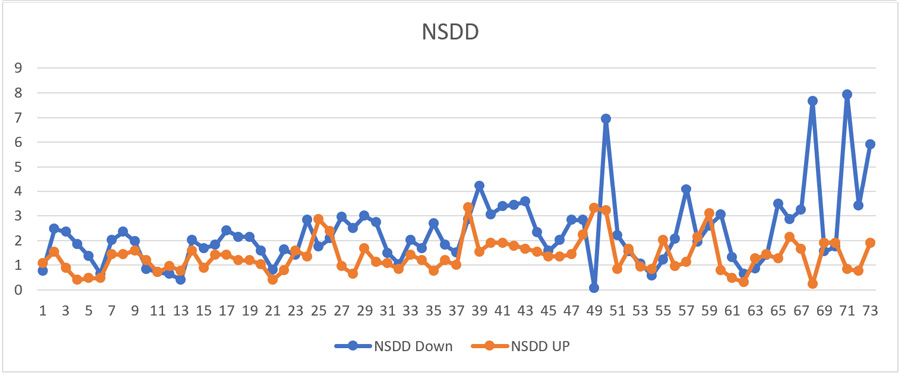

Ranking of insulators has been performed over the past 6 years involving collecting insulator samples and performing ESDD and NSDD measurements to compare findings for the upper and lower surfaces. The top side usually performs better in terms of self-cleaning by strong winds or self-washing by heavy rains. As reported in other publications, the lower side typically collects more pollution due to its deep rib shape, especially so for the anti-pollution profile used on almost all tension strings on the GCCIA’s 400 kV system.

It is noteworthy that pollution seems to be increasing year by year. Moreover, accumulation of solid pollutants combined with a cycle of wetting and drying can make the pollution layer behave like dried cement that is difficult to collect, especially from the bottom surface of insulators.

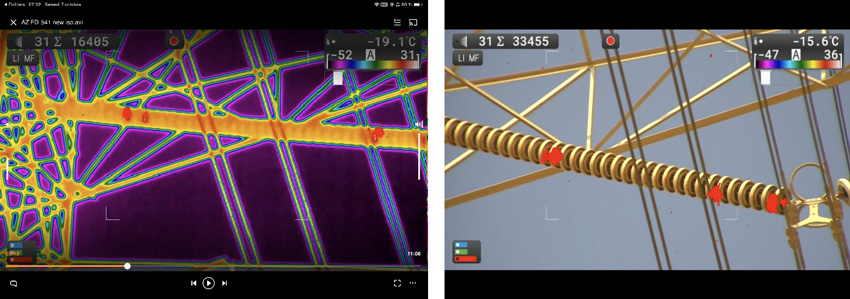

UV Camera Inspection

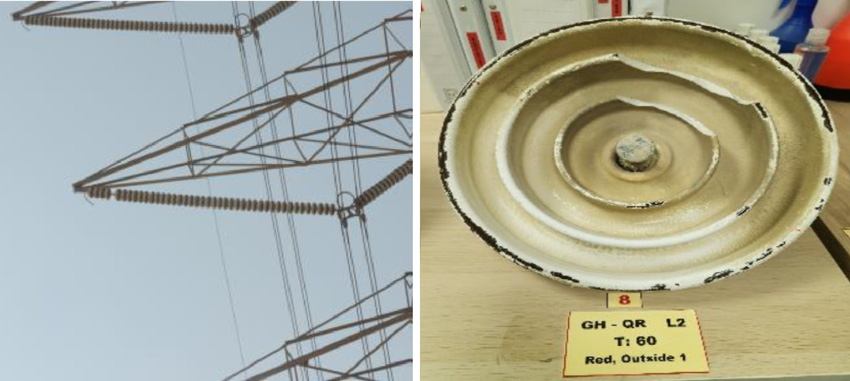

Due to reports of limited numbers of broken porcelain insulators, the GCCIA performed targeted UV camera inspection to help identify cases of possible internal defects (e.g. puncture). UV inspections can be complex science with two inspections of the same tower sometimes showing different results. In this regard, it is important to understand that camera inspections should not rely solely on the findings from only one visit. Results can depend on a variety of factors such as daylight versus night, time and season, humidity, wind velocity and direction, atmospheric pressure, sunshine or cloud and angle of the inspection. Of course, when inspection conditions are ideal, presence of hot spots, superficial discharges, corona activity and even internal defects can be more easily detected. Inspection results will then be easier to interpret by specialists.

After hundreds of targeted inspections, only a single case of suspected internal defects has been found. By contrast, most insulators removed for laboratory investigation showed heavy accumulation of pollution on the bottom side of the disk. In such cases, resulting corona discharges are continuous and localized.

New GCCIA Outdoor Insulation Approach & Conclusions

Despite satisfactory performance of the GCCIA system over the past 15 years, there remains a need to continually seek network improvement. This can be realized based on regular close-up inspections and targeted investigations into those findings that may require additional analysis (e.g. studying the cause of increased shatter rate of coated insulators).

The following are some of the main outputs of this process:

• Close-up inspection and preventive maintenance will be reinforced;

• Due to their established mechanical robustness and strength, GCCIA will continue to use only high quality cap and pin porcelain and glass insulators;

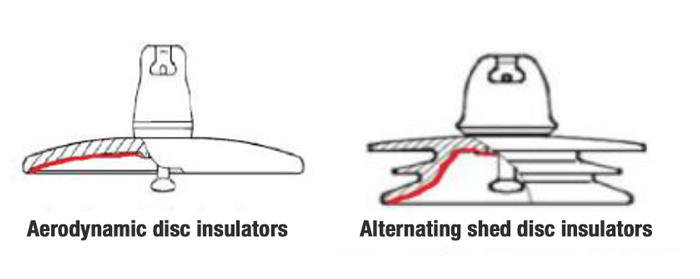

• Based on findings from the last published study dealing with selection and dimensioning of insulators, GCCIA will use ‘open profile’ insulators for most overhead lines in eastern KSA. On the other hand, alternating shed ‘outer rib’ disks will be used where greater creepage distance is needed, such as in very heavily polluted and coastal areas. Both of these open profiles ranked near the top in terms of self-cleaning;

• RTV silicone coatings will be applied on the lower surface of selected insulators (i.e. half coated) since performance is almost the same as for a fully coated insulator. Yet these are easier to handle and install at site with less risk of damage to the coating, as has often been observed on top surfaces during installation or from periodic inspection and maintenance.

References

[1] “IEC/TS 60815”. “Selection and dimensioning of high-voltage insulators for polluted conditions – Part I: Definitions, information and general principles”, 2008.

[2] “Gigre TB 837” – Coating for improvement of electrical performance of outdoor insulators under pollution conditions

[3] R. Znaidi and A. Al Thagafi, “Glass and porcelain insulators coated with RTV silicone rubber In Eastern KSA: GCCIA experiences and maintenance strategy,” in International Symposium on Polluted Insulators, Lahore, 2019.

[4] R. Znaidi, A. Al-Thagafi, S. Hafeez, “Naturally Polluted Insulator Test Stations’’: An Alternative or Complement to Standardized Artificial Pollution and Ageing Testing? 2022 INMR World Congress – Oct-16-19 2022. Berlin

[5] R. Znaidi, A. Al Thagafi and J. Garcia, “HV Insulators coated with silicone rubber in harsh desert environment. Part 1: assessment of natural ageing,” INMR world Congress, Tucson-USA, 2019.