As the power transmission system in India expands to meet ambitious renewable energy targets, insulators on this vast network must contend with challenges brought on by high levels of pollution as well as future climate uncertainty. Ceramic and silicone rubber insulators have both been used but with mixed results. For example, older uncoated ceramic with designs that were not optimized for pollution did not always meet performance expectations and had to be replaced with more reliable options. More recently, ceramic cap & pin insulators have come a long way in terms of improved geometry, construction and values of mean time before flashover (MTBF).

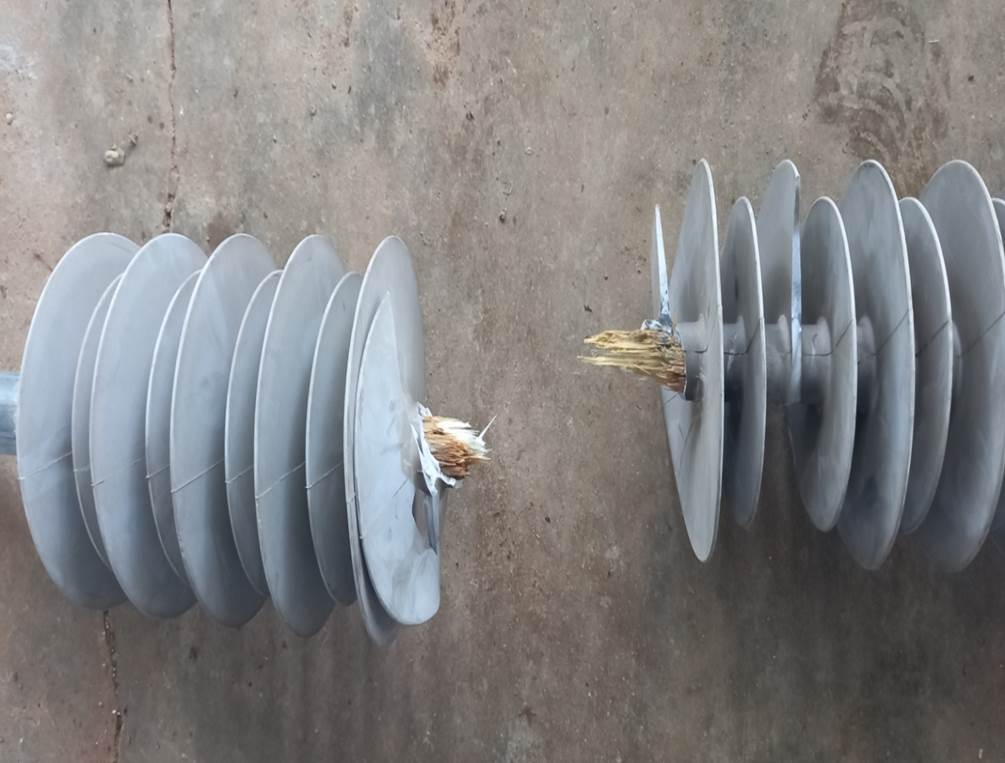

In the case of silicone rubber insulators, there has been an overall decline in quality, likely due to a ‘hypercompetitive’ market situation. With climate change exacerbated by acid rain from coal-fired power stations and other sources, failure rates of lower quality insulators are anticipated to rise due to factors such as de-polymerization, brittle fracture and accelerated loss of hydrophobicity, leading to flashovers. This is only expected to accelerate a new trend toward using RTV coatings on ceramic insulators to eliminate flashovers and mitigate risk of catastrophic line drops.

Climate, Pollution & Impact on Silicone HTM Insulators

India faces the brunt of climate change. According to the Global Climate Risk Index (2021), the country ranked seventh in terms of being ‘most affected by the devastating impact and has 65 of the 100 most polluted cities in the world. As a result, acid rain due to higher ambient SOx-NOx levels is expected to affect performance of hydrophobicity transfer material (HTM) insulators in years to come. For example, alumina trihydrate (ATH), the inorganic filler in silicone rubber, can dissolve under acid rain, increasing heating from discharges under dry band arcing and possibly causing irreversible breakdown of the filler. Moreover, hydrophobic groups in the hydrocarbon methyl chain in silicone rubber are at risk of degrading under acid rain. Consequently, the surface of aged HTM can roughen and lose hydrophobicity. Surface discharge current can increase and insulator life decreases.

The Indian Power Grid

The power transmission system in India is one of the largest synchronous grids in the world, spanning a nation with varied climatic conditions including a 7500 km coastline, salt flats, sand deserts, mountain ranges, dense winter fog and some of the wettest places on earth. Large-scale urbanization as well as industrialization and the need to cater to fast emerging RE sources continue to push growth, such that doubling of this network is foreseen. The Central Transmission Utility – Power Grid Corporation of India – is said to operate at 99.86% system availability and carries 45% of the country’s total transmission capacity. The rest of the grid is operated by private and state utilities – some of which continue to be plagued by inefficiencies, fund shortages and right-of-way challenges.

Plan to attend the 2023 INMR WORLD CONGRESS in Bangkok, where a presentation by Neelesh Arora will provide a comprehensive overview of service experience in India with alternative types and designs of insulators. Based on this service experience, he will review key considerations in insulator design to combat the impact of climate change and elevated pollution conditions. He will be joined by many other experts to discuss how best to assess and mitigate impact of pollution on insulator performance and service life.

[inline_ad_block]