In spite of years spent developing sophisticated laboratory tests to reproduce the stresses faced by network components in service, many power engineers still believe that experience at an outdoor test station offers the definitive measure of expected field performance under adverse conditions. For this reason, there is continued interest in research at test stations where the principal characteristic is cycles of severe pollution accumulation and natural cleaning that are difficult to replicate in a laboratory setting.

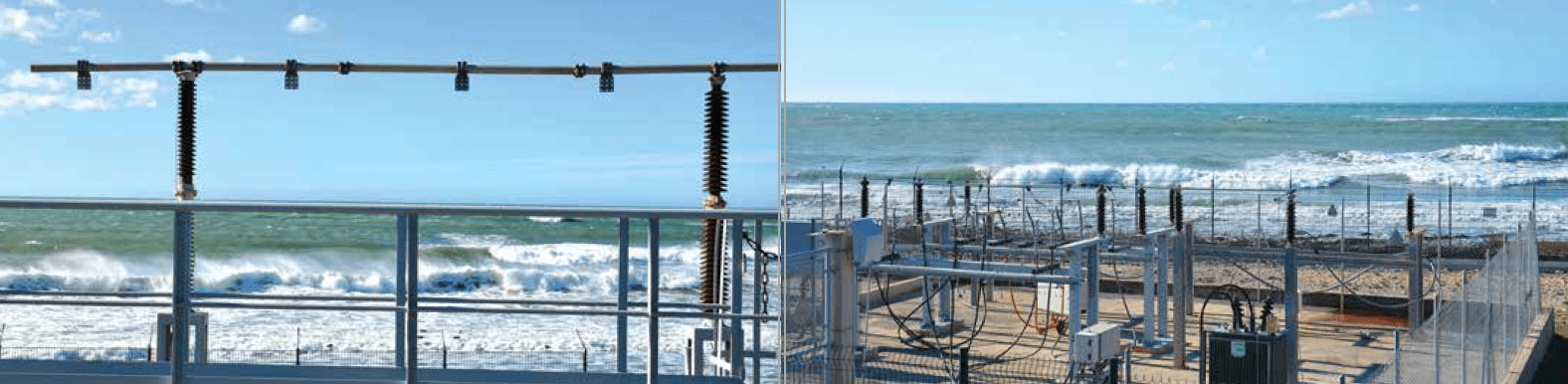

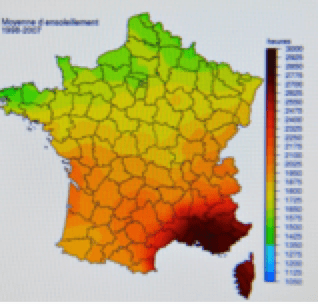

One such test station is located near the French port city of Marseille, on the Mediterranean coast. What makes the site so suitable for its purpose is that it combines heavy maritime and industrial pollution, thereby creating a particularly demanding service environment. There is also intense UV radiation spread over the whole year. If a component performs well at this test station, it is reasonable to believe that it will do so in the field as well.

INMR first travelled to Martigues 16 years ago, accompanied by the late Claude de Tourreil and reported on the visit in an article appearing in the Jan-Feb 2001 issue. In February 2017, INMR returned to Martigues, along with staff from the Laboratoire des Matériels Electriques of Electricité de France (EDF) who owns and operates the facility.

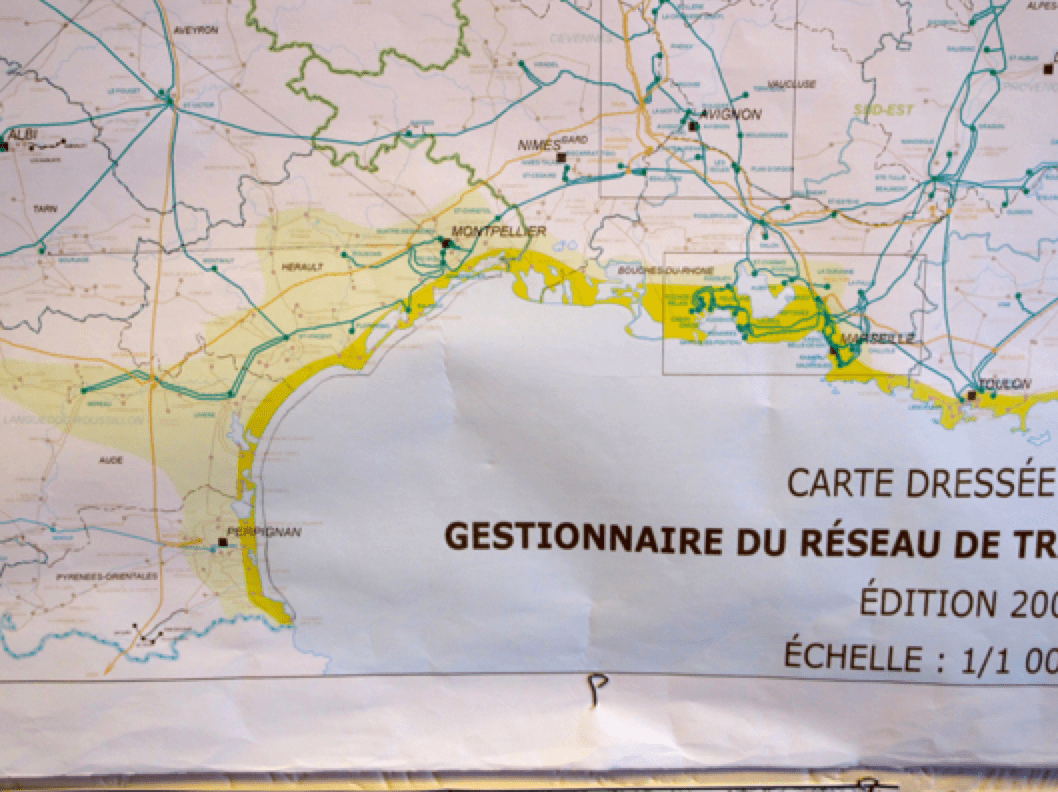

Martigues Test Station is one of the world’s longest serving for electrical equipment and components, with a history spanning five decades. Established in 1968 primarily to study behavior of glass and porcelain insulators under maritime and industrial pollution, it is only meters from the Mediterranean and near huge petrochemical and refining complexes. Indeed, while many would not think of France as a country facing severe environmental challenges, this particular area could be deemed a true test of electrical insulation under some of the most challenging service conditions.

CLICK TO ENLARGE

Starting in the 1990s, the research being performed at Martigues began to shift away from ceramic and more to composite type insulation. One of the goals was to compare findings from accelerated ageing tests in the laboratory with those obtained in this natural setting. It was hoped that this would help confirm whether the acceleration factors being proposed were reasonable or not. Eventually, this effort was discontinued as staff came to the realization that acceleration factors could not be generalized but rather depended on specific insulator design and material.

CLICK TO ENLARGE

Today, Martigues is mainly a developmental test station where new designs and insulation materials can be subjected to worst-case service conditions. Another change over the years has been the expansion of test objects from mainly line insulators to include ancillary equipment such as surge arresters, cable accessories, CTs and so on.

CLICK TO ENLARGE

CLICK TO ENLARGE

Christian Pons is the R&D engineer who presently oversees research undertaken on insulators at Martigues and he cooperates closely with Dylan Catoir, one of the supervisory technicians who visit the site on a monthly basis. They work together with Laurent Basuyaux, a test engineer in charge of the 5000-hour test chamber at EDF’s Les Renardières testing facilities south of Paris.

CLICK TO ENLARGE

Pons explains that one of the main considerations when operating a test station such as Martigues is ensuring client confidentiality. He notes that while IEC accreditation criteria for confidentiality do not apply to test stations, EDF still follows much the same rules used in its laboratories. This means that whenever one customer visits the site to monitor the condition of their test objects other specimens are hidden by black cladding that is later removed.

CLICK TO ENLARGE

The key parameters being monitored on any test object at the site include leakage current, meteorological conditions and voltage, the last intended to record any dips or overvoltage situations that might create anomalies. The data acquisition system has a 3G connection to Catoir’s dedicated computer at Les Renardières, allowing EDF’s technicians to examine data in real time or download data over any desired time frame. Customers can then request how they prefer the information be transmitted to them.

Says Pons, “we discuss with every client what their information needs are and we exchange this data internally before submitting it to them.” Should there be a failure, due for example to flashover on an insulator string, Basuyaux will typically contact the customer to discuss their desired next course of action. The test object can be removed and sent back for forensic examination or photos can be taken of its condition.

CLICK TO ENLARGE

CLICK TO ENLARGE

There are several test bays at Martigues, with phase-to-earth voltages of 245 kV, 140 kV, 58 kV, 13.8 kV and 2.2 kV – all AC. There is also a 24 kV phase-tophase yard, mostly used for cables and accessories. These different bays can accommodate a range of different test items from insulators to surge arresters to instrument transformers. Samples can also be installed on dedicated test platforms where the client can remove them at desired intervals for close examination.

CLICK TO ENLARGE

A large part of the test station is without applied voltage and serves to allow assessing behavior of samples under wind, UV, temperature and humidity. For example, external electricity meter boxes are tested at the site to determine how well they stand up to severe weathering.

Pons emphasizes that most test objects at Martigues are there for long duration and installed at least a year in order to be exposed to all weather cycles and endure some minimum level of pollution accumulation. This is important since if seasonal winds come mainly from the sea, humidity is high but if these winds are from the north, insulation surfaces are dried and there is no activity.

A directional dust deposit gauge (DDDG) is installed on site and is emptied and analyzed by Catoir each time he visits. Typical findings confirm that level of pollution being deposited on test objects depends greatly on wind direction. Says Pons, “we always check wind patterns to know the direction of primary pollution exposure. This allows us to know whether test specimens are more exposed to maritime or to industrial pollution. For example, the station receives sand deposits from as far away as the Sahara that are carried over the sea, become charged with humidity and fall here. It is also exposed to periodic clouds of SO2 from nearby industry that create ideal conditions for customers to test how well their products also stand up to corrosion.”

Pons points out that a DDDG is essentially a passive device and simple to operate at minimal cost. However, to use it effectively it is important to also analyze weather and local industrial activity in order to best interpret the findings. This includes remote monitoring from Les Renardières of any exceptional events such as local wilfires or heavy storms and rains that might contribute to natural cleaning. “It is important to regularly check for unusual variations of this sort,” he notes, “so as to best understand what is really going on.”

CLICK TO ENLARGE

Hydrophobicity tests are also undertaken on each shed of certain test specimens using the method that sees de-mineralized water sprayed from a distance of 20 cm. One interesting finding over the years, according to Pons and Catoir, is that industrial pollution can have a much different impact on reducing hydrophobicity than does salt contamination from the sea. While there is no distinct border between the two surface areas, they conclude that type of industrial contamination deposited plays a decisive role in the extent to which hydrophobicity is being lost.

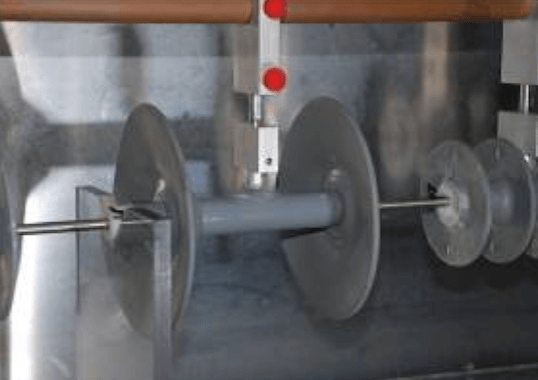

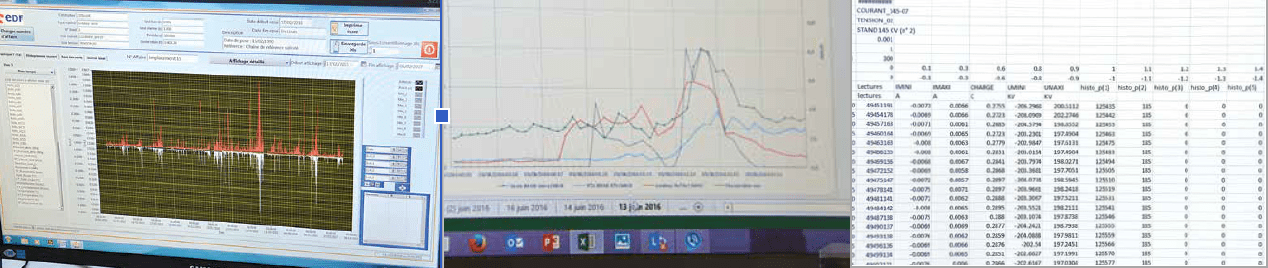

Each test insulator or related component installed at Martigues is fitted with a metallic ring to catch leakage current, the parameter that is usually of greatest interest to customers. The wire goes to a shunt that picks up voltage and the signal is conditioned to impedance before going to the station’s data acquisition system. This system has recently been equipped with entirely new software specially adapted for EDF needs. “This is not a commercially-available product adapted in terms of factors such as the number of signals coming in from the test station,” states Pons. “Rather, it was developed exactly to meet our needs.”

CLICK TO ENLARGE

CLICK TO ENLARGE

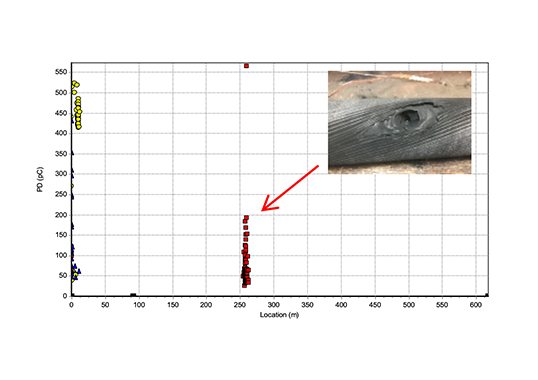

Pons explains that this customized software not only measures leakage current but in parallel also counts pulses over any specified trigger level, without need for calculations. Catoir can then use the software to obtain an overview of the entire test station along with the possibility to set up a dedicated channel for any customer’s product. For each such channel, information is also recorded on all meteorological parameters and updated every five minutes. This allows comparison of behavior of insulators made from different materials to that of a glass reference string, already tested in a salt fog chamber to establish the relationship between leakage current and ESDD level.

Catoir can also control the data acquisition system in Martigues remotely from his computer at Les Renardières, allowing him to check for signs of trouble, e.g. due to storms or other unusual events. He typically will enter the period of measurement and obtains a graph showing when any activity appears on a test object such as an insulator. With a calibration curve, he can then make a chart or convert the data to an Excel file in CSV format. “After that,” says Pons, “we check the data to see if the voltage has been stable over the period and calculate standard deviation of minimum and maximum charge. We monitor weather data as well, including atmospheric pressure, wind speed and direction, rain, dew point and maximum UV radiation over each day. There is also a column showing pollution class based on a calibration curve obtained from laboratory testing.”

CLICK TO ENLARGE

Another possibility, notes Pons, is carrying out observations at night. This allows superimposing leakage current with findings from UV and infrared cameras. Says Pons, “it is often interesting to compare leakage current with what can be observed visually. We are also able to easily adapt any data treatment to meet the customer needs because of our specialized software. Clearly, data can always be processed but what is now different is how easy it is to extract. That is the advantage of our new software.”

CLICK TO ENLARGE

EDF sends a report to customers along with photos and all relevant data but with no interpretation of what this might mean. “Basically,” remarks Pons, “we tell the customer what we saw. Based on this, they can decide whether or not to come here. We are always ready to show them the site, if asked.” Pons adds that it is not unusual that customers are surprised by what they discover on the behavior of their test objects due to the extreme environment of the test station. “If your test object can pass some years at Martigues without trouble,” he says, “it is indeed a good sign regarding its expected pollution performance.

One area at the test station has been designed to test slabs of different polymeric insulation materials exposed to pollution and high UV. Manufacturers can then request these be removed at specified intervals to be tested later in their laboratory.

Pons emphasizes that a test station such as Martigues is not focused on conducting standard tests to obtain qualification from end users. Rather, it supports R&D work in developing new insulation materials and new product designs.

“There is no IEC standard that governs such a test station,” he remarks, “since one cannot always predict weather. Therefore, we build our testing according to the specific needs of the customer. For example, they can request data only for those periods where humidity is over 80 percent or when there is some minimum leakage current present. Thanks to our specialized new software, we can easily adapt the data treatment in such ways. Of course, a test station such as this can always process data. But what has been different at Martigues over the past 18 months is our capability to control the station live directly from Les Renardières and also how easy it now is to extract any data requested. That is our strength.”

CLICK TO ENLARGE