[inline_ad_block]

Attend the 2019 INMR WORLD CONGRESS this October in Tucson, Arizona to hear a landmark presentation by Professor Volker Hinrichsen. One of the world’s leading experts and opinion leaders in the field of surge arresters, Dr. Hinrichsen worked with Siemens from 1989 to 2001 in the position of R&D Director of the Surge Arrester Division. Since then he has been full professor in high-voltage engineering at one of Germany’s leading academic institutions in high voltage power engineering – Technische Universität of Darmstadt . He is member of several IEC, IEEE & CIGRE Committees and is Chairman of IEC TC37 (Surge Arresters) as well as Convenor of IEC TC37 MT4 – the maintenance team responsible for all high-voltage arrester test standards. His most recent research activities in the field of surge arresters have been on energy handling capability and on optimization of external grading systems for UHV arresters.

Gapless Metal-Oxide (MO) arresters came to market in 1975, after the serendipity discovery of ZnO resistors by Matsushita Electric Industrial in 1968 and subsequent intensive development towards overvoltage protection devices for application on electrical power systems.

CLICK TO ENLARGE

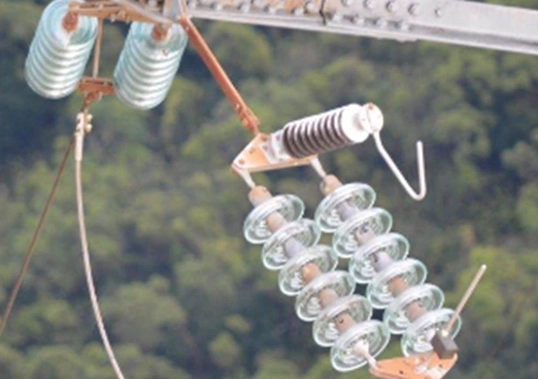

The first test standards on these novel devices were published only around 1990. As such, gapless MO arresters are comparatively young devices with only short service history. Nonetheless, these have undergone rapid development during the past three decades. For example, by the mid-1980s in the case of distribution class and by the early 1990s in the case of high voltage station class, MO arresters were among the first power system apparatus equipped with polymeric insulation. This has since become state-of-the-art in distribution and now increasingly widely applied in transmission systems. Progress has also been achieved when it comes to significantly improved performance of MO resistors, helping to make arresters among the most reliable components found today in any electrical power system.

CLICK TO ENLARGE

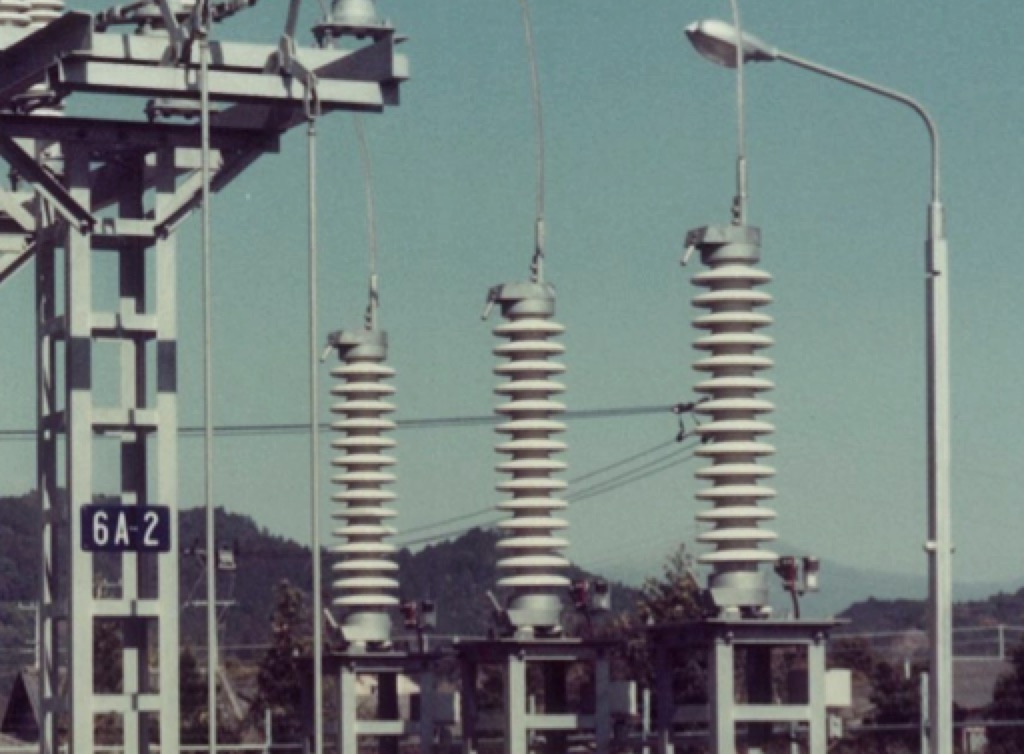

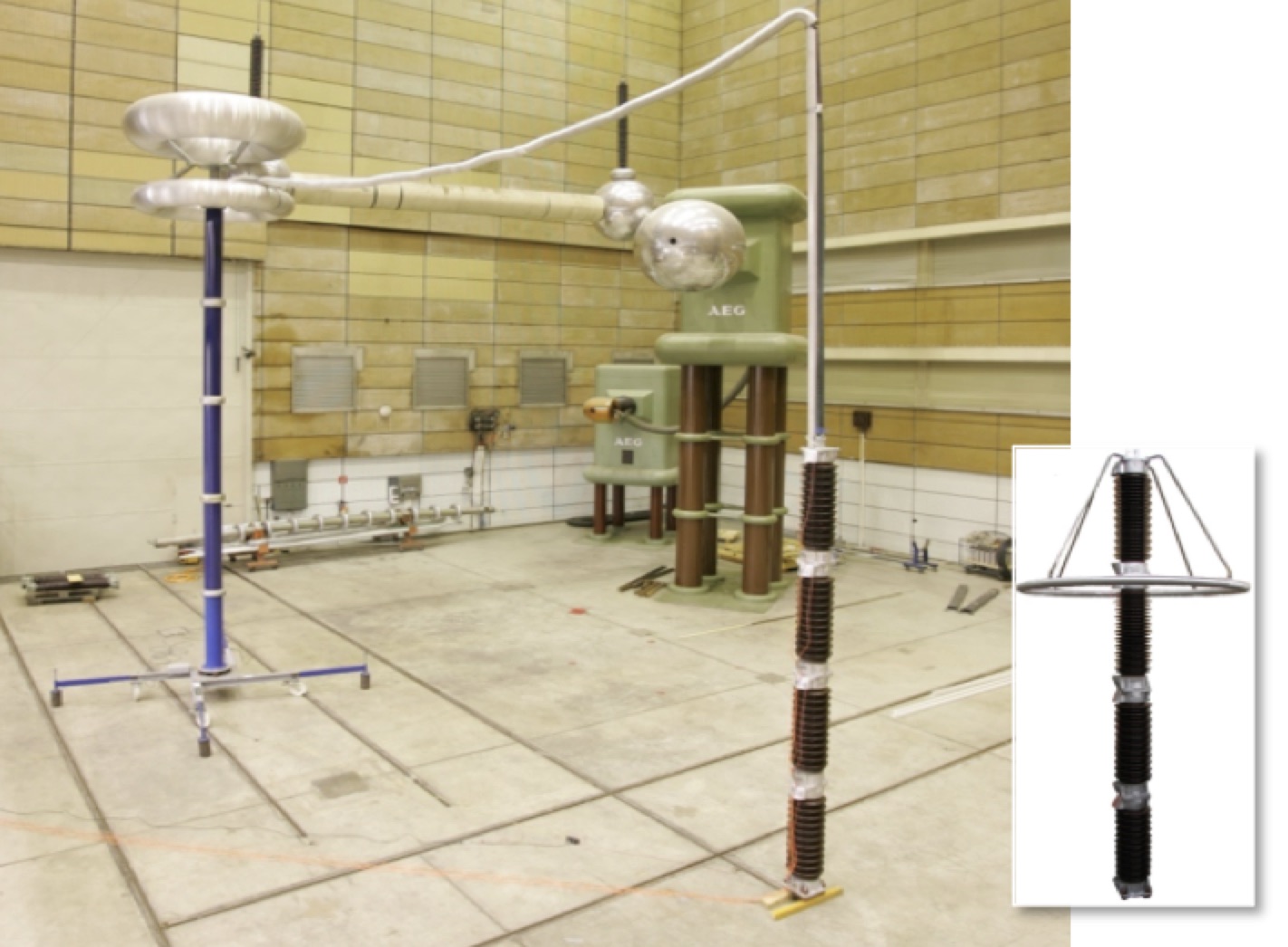

Following virtually complete replacement of the former gapped silicon carbide (SiC) arrester technology, new MOV arresters have expanded beyond ‘simply’ overvoltage protection at substations to include important new applications. Examples are multi-column UHV station arresters for systems above 1000 kV (e.g. as in China and India for 1100 kV), HVDC arresters at converter stations (of which valve protection arresters are the most important), distribution and transmission line arresters, with and without a series gap, up to the highest system voltages, huge arrester banks in Flexible AC Transmission Systems, e.g. for overvoltage protection of series capacitors in case of line fault. Among the most recent developments is application as indispensable energy absorbers in emerging HVDC circuit breakers (also being discussed at this 2019 INMR WORLD CONGRESS).

CLICK TO ENLARGE

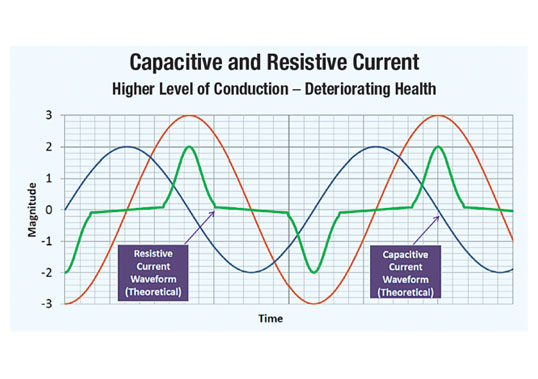

Energy handling capability and potential electrical degradation of MO resistors has been a concern from the start. This is because, due to permanent connection to the line, a gapless MO arrester can theoretically suffer thermal runaway after excessive energy input or due to deterioration of its non-linear voltage-current-characteristic. Fortunately, these days electrical degradation is no longer a potential problem for experienced arrester manufacturers. Moreover, demanding test requirements in current arrester test standards help avoid any unexpected setback to the high-level of this technology so far achieved.

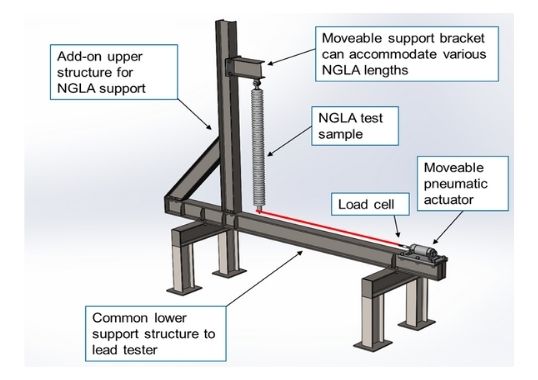

At the same time, modern, unconventional applications require approaches in specifying and verifying energy handling capability other than just by line discharges, as has been the case for station class arresters. Supported by Cigré work, test standards have permanently improved to cover all aspects of today’s arrester applications though there is still work to be done. At the same time, more than for any other apparatus, arrester test standards within IEC and IEEE are now being harmonized. This will ultimately result in a current project of a dual logo standard on all types of line arresters, as currently being prepared by a joint Working Group of IEC and IEEE. (Thus topic will be reviewed in depth at this event by Jonathan Woodworth).

CLICK TO ENLARGE

Among the exciting ongoing developments in engineering is that simulation tools have become powerful enough to make it possible to optimize EHV and UHV arrester designs with respect to their external grading systems and thermal stability limits utilizing non-linear, fully coupled electro-thermal simulation. This has opened the door for design of UHV arresters with considerably reduced need for full size testing in a laboratory – something that is increasingly difficult in these voltage levels. This trend is supported by smart approaches within the test standards with regard to dielectric withstand tests. Based on sufficient experimental experience, need for such tests can be eliminated if certain minimum clearance requirements are fulfilled. Thus, developing and qualifying new UHV arresters becomes possible without need for full-scale 1000 kV test facilities.

Prof. Hinrichsen’s contribution at the 2019 INMR WORLD CONGRESS will address the ongoing challenges during continued development of gapless MO surge arresters. Special focus will be placed on recent research performed covering energy handling capability and on the external grading systems to mitigate undesirable effects from uneven electric field distribution in the case of arresters longer than about two meters.

CLICK TO ENLARGE