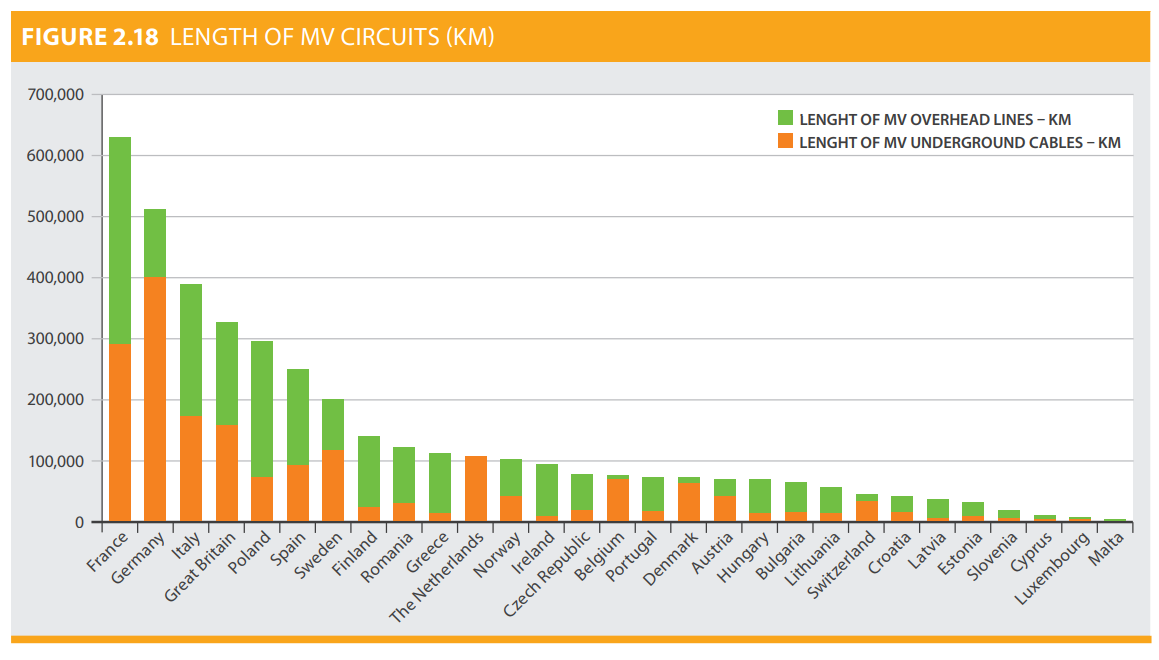

Underground cables have come to represent the core of the distribution system in many countries, such as across parts of Europe. Italy, with its specific topography and high level of electrification, scores especially high both in terms of overall line length (395,000 km) and density of MV distribution lines, i.e. 1.3 km of lines per km2 of land. Initially used in major cities to optimize space utilization, increase safety and reduce visual impact of overhead lines, their use has progressively increased outside metropolitan areas as well. This has been largely due to their intrinsic reliability and reduced vulnerability to contacts of trees, heavy winds, wet snow, failure of supports, accidents due to bare conductors, etc. The Italian MV distribution system is laid underground for nearly 45% of its extension (total MV cables 175,000 km).

In terms of cable technologies, the oil or resin impregnated paper used systematically until the end of the 1970s has been progressively replaced by XLPE extruded insulation. In most cities, however, mixed technologies are still the norm and some 50 to 60% of old resin-insulated cable portions are jointed to dry sections by means of ‘transition joints’.

Solutions applied for cable jointing cover the entire technological spectrum from belted joints to resin joints, from heat shrink types to cold shrink types. Heat and cold shrink joints are regarded as the best technologies since they can be installed rapidly in the field and can be energized only 30 minutes after mounting. Cold shrink joints are currently the most widely used in cable projects, whether new installations or repairs, because they are modular. Based on pieces made in the factory under a quality control system, they require only simple manipulation and significantly shorten outage time of the line, thus improving a system’s power quality parameters.

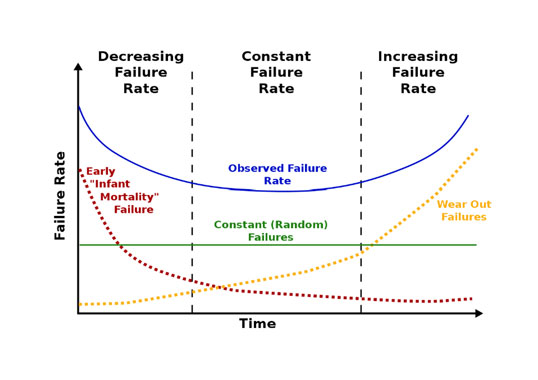

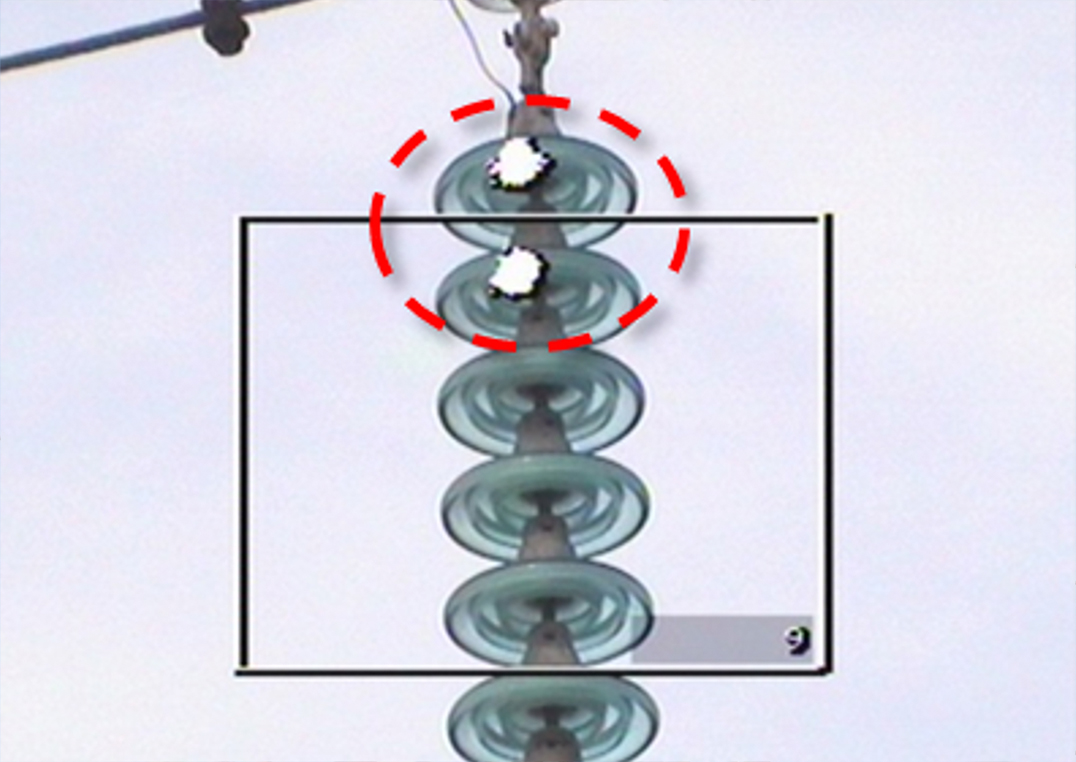

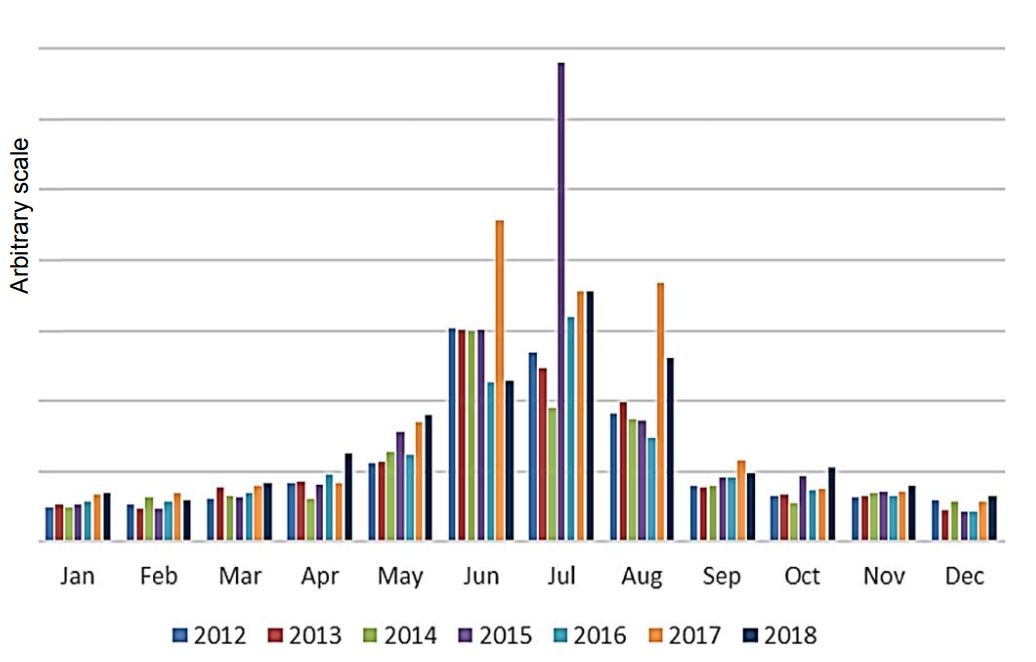

Unfortunately, the evolution of cables, joints and terminations has not been accompanied by any significant increase in line reliability. In fact, it has been observed that distribution system operators across Italy experience significant increases in failure rates in their medium voltage underground cable networks and this is generally concentrated during the hottest periods of the year (i.e. from May to October).

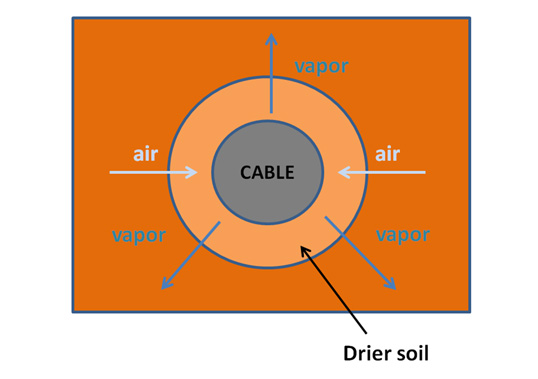

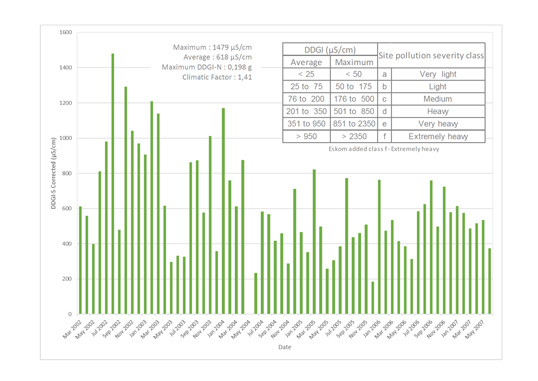

The problem is most severe in the presence of heat waves characterized by long lasting ambient temperatures that are well beyond historical levels and combine with lack of precipitation and often high relative humidity. These conditions can be a prerequisite to poor heat dissipation of highly stressed underground cables. For example, Fig. 2 highlights this situation for several regions and shows unexpected, non-accidental MV cable joints failure statistics from 2012 to 2018 as reported by the distribution system operator of a large town across different months of the year. The Y-axis is not reported because the aim here is to depict the trend, namely that failures occur more often in some years with respect to others, because of the variable frequency and duration of adverse environmental conditions, particularly intense heat waves and low rainfall rate.

Attend the upcoming 2023 INMR WORLD CONGRESS in Bangkok to benefit from a series of lectures by experts on cable testing and condition assessment, including an important contribution by Michele de Nigris of RSE in Italy. Mr. de Nigris will explain the characterization and understanding of recurrent cable joint failures under severe environmental and electrical stresses. He will also review research into the phenomena contributing to the threat, assess related vulnerability of MV cable networks and components and identify corrective measures to increase their resilience against such recurring extreme situations.

[inline_ad_block]