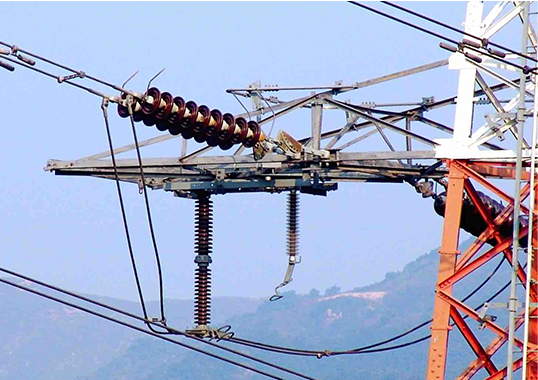

Application of line surge arresters (LSAs) is intended to prevent lightning induced flashovers. While externally gapped line arrester (EGLA) technology is now commonly regarded as the most appropriate, questions can still arise:

• Is it optimal to protect every phase conductor?

• How to monitor the condition of LSAs over the years to be confident that they are still protecting the line?

• Is it possible to confirm that they have performed their protection duty and, if so, how often?

This edited contribution to INMR by Florent Giraudet of Metarresters.com aims to answer these fundamental questions.

Due Diligence

Utilities and power system operators often confront difficulties when analyzing the lightning performance of their lines and especially so when selecting the most effective and affordable method to reduce lightning induced outages. Typically, the decision to install LSAs is viewed as ‘a last resort’ since these are sometimes perceived as too costly and not sufficiently reliable. But not investing in LSAs to reduce lightning outages can also carry severe consequences, including:

• financial damages;

• penalties from customers;

• costs linked to momentary outages;

• risks to grid stability & continuity of service;

• increased need to utilize circuit breakers.

The first challenge in the process to reduce lightning induced outages is to identify the critical line sections and start a due diligence process. This consists of:

• identifying lightning induced outages vs. outages from other causes;

• investigating Ground Flash Density (GFD) and Keraunic level;

• verifying insulation coordination;

• on-site measurements of tower footing resistance;

• inspecting shield wires/OHGW.

A decision matrix should then help in evaluating the situation and prioritizing options to mitigate lightning outages with cost-effective solutions. Unfortunately, this is not an easy process since biases can come into play due to missing data, incorrect information or traditional biases.

Working with ‘Real-World’ Data

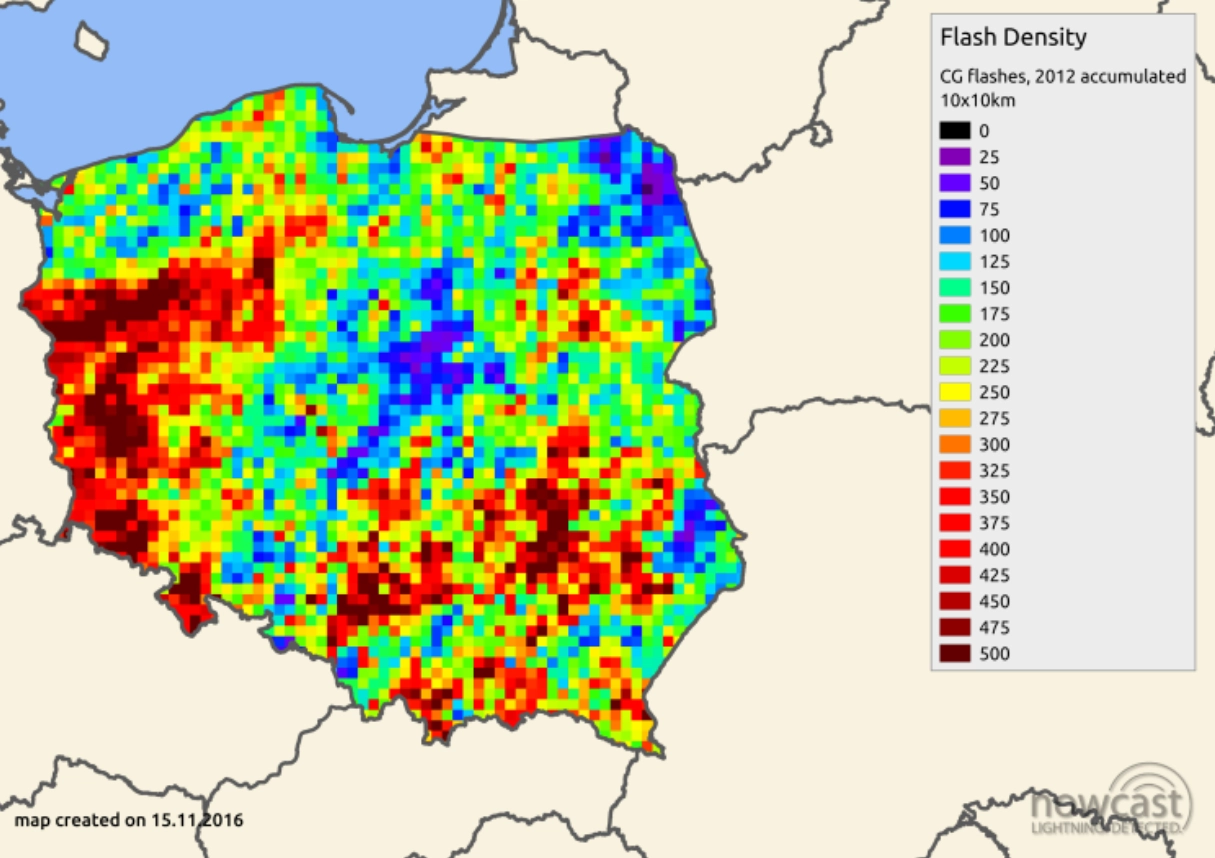

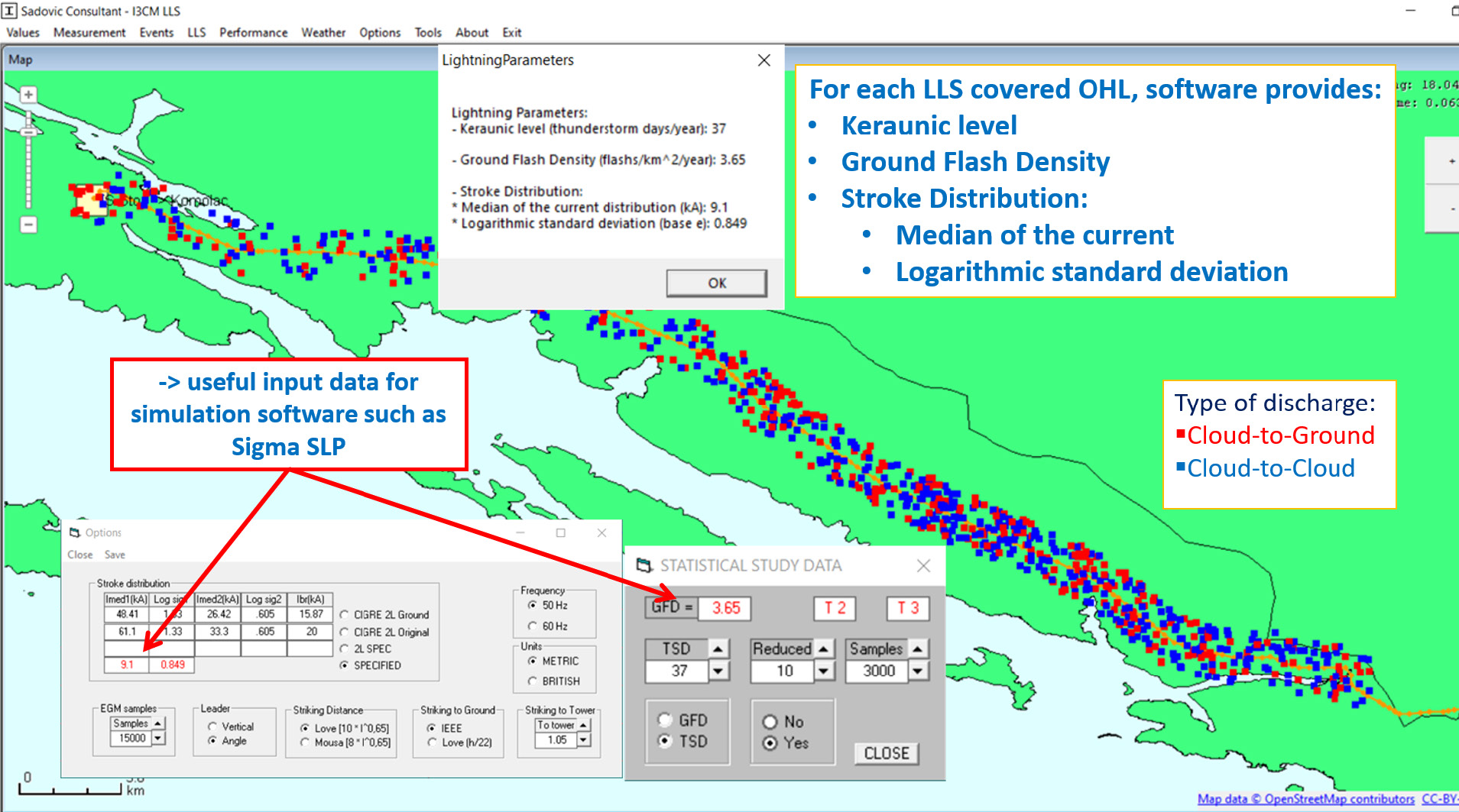

Lightning detection techniques have undergone improved performance in recent years and modern hardware/software solutions such as I3CM LLS help users to record and analyze all lightning activity in an area of interest. For example, in the screenshot shown in Fig. 2 a typical 1 km buffer has been chosen along an overhead line of interest. Primary information is then extracted for further study, such as:

• Ground flash density or keraunic level;

• Cumulative stroke distribution, i.e. median of stroke amplitude and logarithmic standard deviation.

Having taken care to carry out appropriate field inspections and measurements, it is then appropriate to report on grounding conditions that are essential for effective system studies, including:

• Soil resistivity;

• Tower footing resistances (TFR).

Simulating & Defining Targets

Simulation software can help optimize investment in protection by running a computation of lightning performance. Such software allows modeling a transmission line to analyze impact of lightning strokes on performance and simulation can be made on systems with and without application of LSAs. Sigma SLP, for example, first commercialized in the early 2000s and based on research performed in collaboration with experts, includes a special feature to run simulations on the complete line (i.e. for various TFRs and line spans) including automated LSA placement. This helps users to minimize the budget for any desired level of improvement. As such, a customized stroke distribution model can be based on real data instead of using excessively conservative models that can vary depending on country. A recent update to this software allows defining failure rate probability based on specific stroke distribution models.

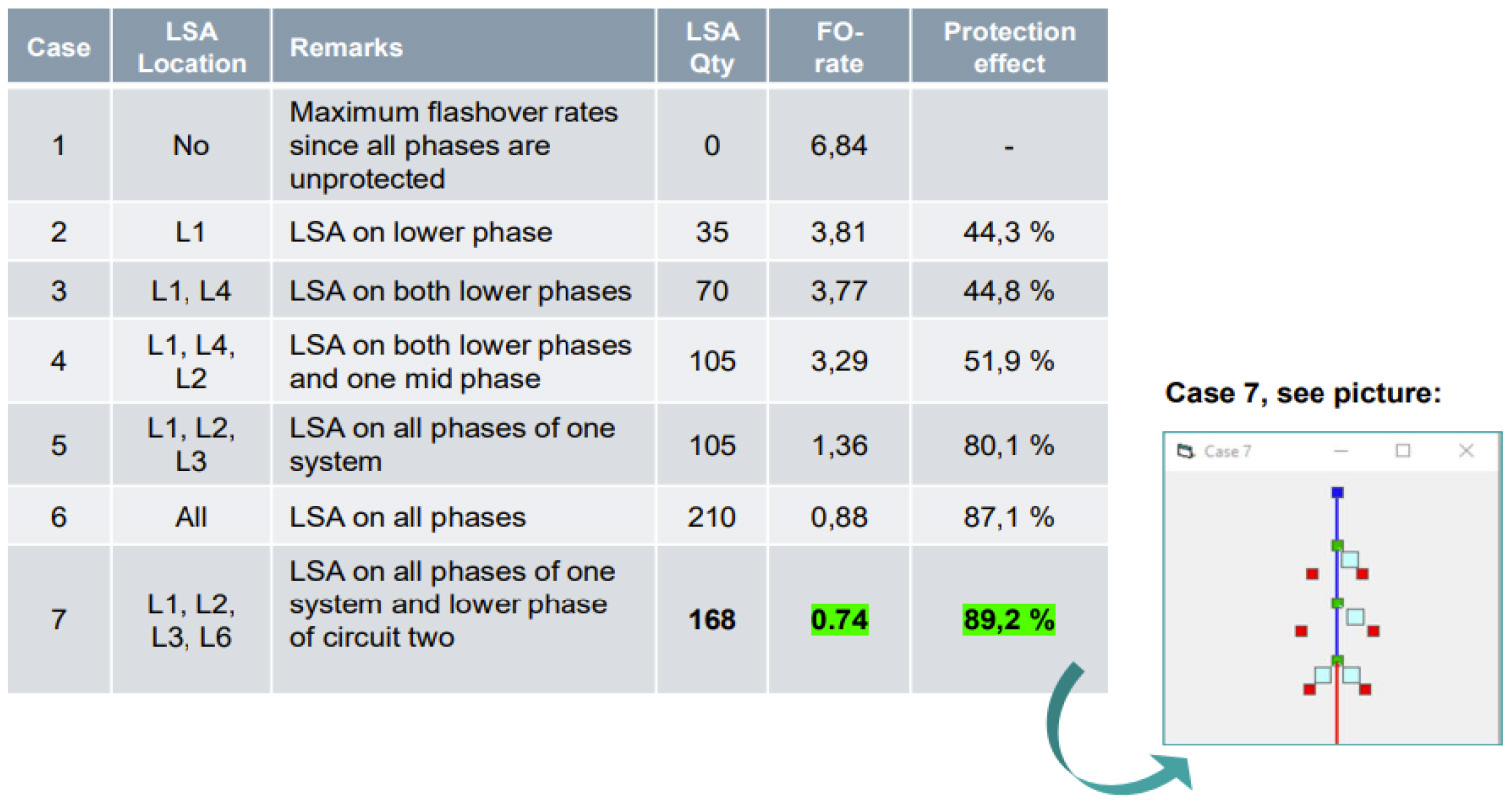

Users can then more easily define their budget (i.e. number of LSAs to install) in order to reach some target performance level, measured in terms of outages/100 km/year. Experience has confirmed that studies of this type can achieve significant levels of improvement without need to completely equip a line with LSAs.

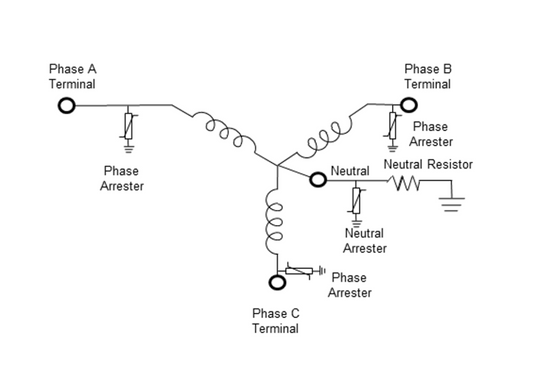

As example, the following results were obtained for a 170 kV shielded double circuit line:

• 89.2% improvement (reduction in outages) by protecting only 4 phases;

• 80.1% improvement (reduction in outages) by protecting only 3 phases while resulting in a 100% improvement in avoiding double circuit outages.

True Digitalization of Monitoring

Monitoring is an issue of concern frequently expressed by utilities and system operators since LSAs are regarded as assets that can fail. Field experience over many years shows that when properly designed, dimensioned, manufactured and installed, LSAs should not fail and reported cases of failure are usually low. Nonetheless, should a failure occur on any unit, this does not jeopardize the system because the other LSAs continue to perform their role along the line. Given this, condition assessment and preventive maintenance, which could be costly and complex, is not justified. At the same time, monitoring solutions might still prove effective in maintenance to detect failures and plan for replacement.

Today, proven technologies can tackle the challenging process of line monitoring and failure detection, e.g.:

• Lightning location system (LLS);

• Double-ended traveling wave (TW);

• Synchronization GNSS time stamp;

• Weather data analysis;

• Online software application with dedicated functions.

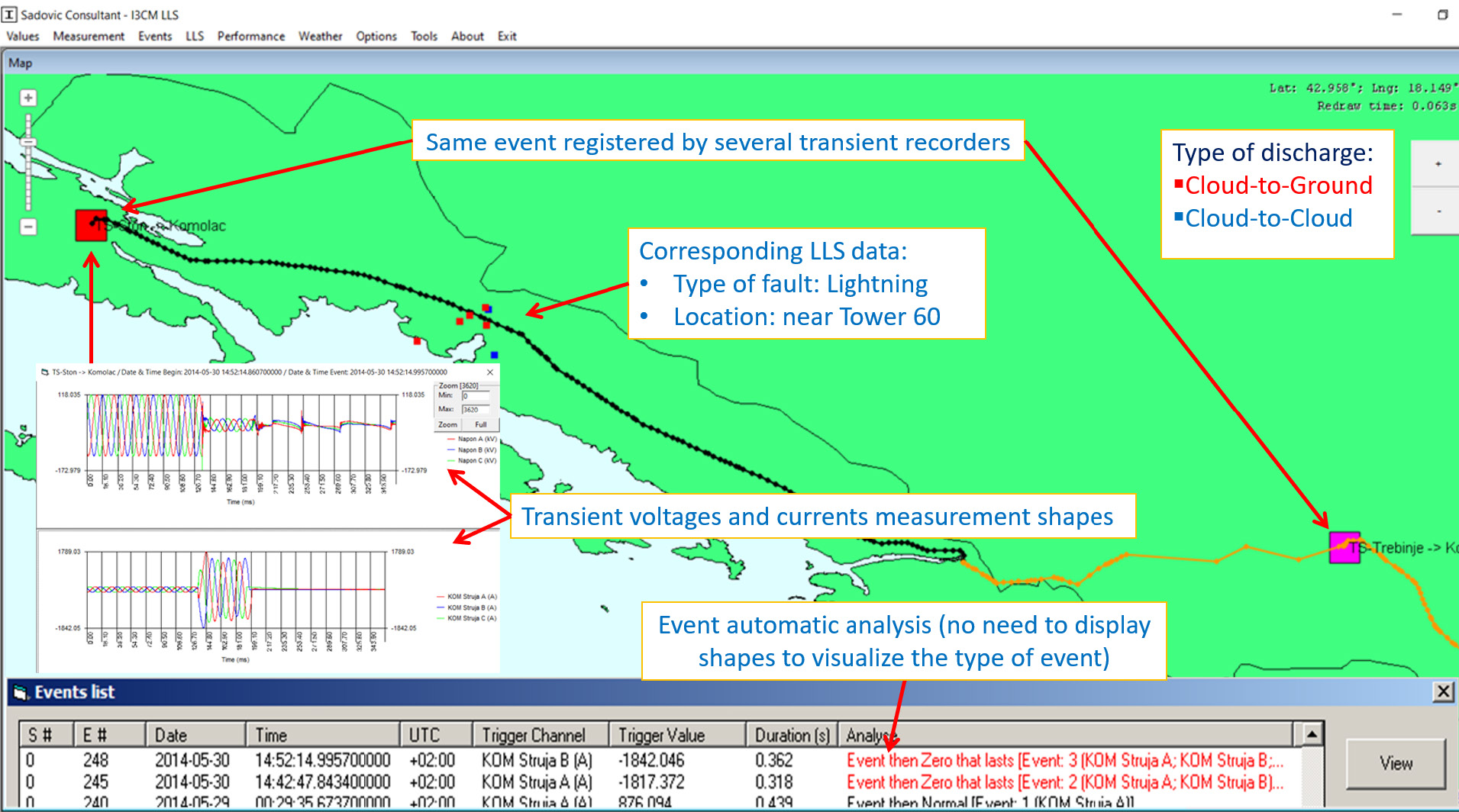

I3CM LLS, for example, includes all these technologies and is a convenient real-time online monitoring tool to facilitate identification, categorization and location of line faults. This goes much further than simply LSA failure detection since key features include:

• helping categorize faults and providing real-time notifications to support decisions and prioritization;

• allowing lightning outages to be detected and localized with high accuracy (~60 m) and their type differentiated (i.e. backflashover versus shielding failure). Weather data providers can be queried if LLS data do not match;

• ensuring that suspicious faults can be precisely localized and that inspection crews can be sent to the right location;

• customizing a digital twin of the line in I3CM LLS to provide specific features such as LSA failure detection.

Japan: A Model of Reliability

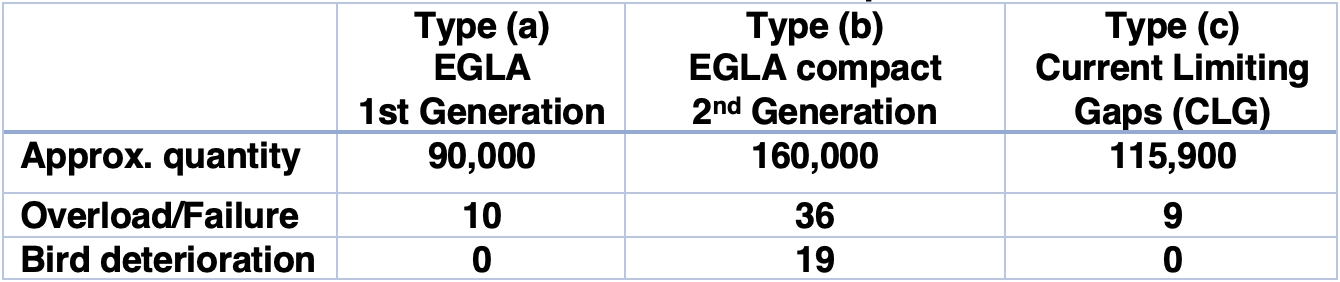

According to a report from the Central Research Institute of the Electric Power Industry (CRIEPI), about 365,900 units were installed in Japan in 2009. About 120,000 of these were current limiting gaps (CLGs), which is an alternative to metal-oxide arrester technology. Therefore, about 250,000 EGLA units have been in operation in that country since the 1980s.

It should be noted that dedicated monitoring of EGLAs does not apply in that country since inspections are performed regularly on transmission towers, insulators and also on EGLAs. Moreover, Japanese utilities and system operators are able to localize any fault should a lightning induced outage be detected. Over 20 years, the number of overloads/failures reported on the population of 365,900 units has been only 55 – an extraordinary statistic that confirms the inherent reliability of EGLA technology as well as its potential to improve lightning performance on transmission lines compared to biases and misconception.

More specifically, looking at modern compact EGLAs made with light-weight polymeric housings and optimized ZnO block sizes, only 36 cases of failure were reported out of some 160,000 units installed across the country over a period of 10 years (see Table 1). In other word:

Failure rate of compact EGLAs = 0.0225 failures/1000 units/year

Moreover, in view of data on incidence of failure, there are countermeasures that will ensure failures rates close to zero by adapting the charge transfer capability of the SVU and improving the tightening system of EGLA sets (i.e. better design and more extensive vibration testing).

Conclusions

LSAs are still an underrated method for improving lightning performance of overhead lines. Biases and misconceptions sometimes keep LSAs out of the spotlight even though experience with EGLA types has shown extremely high reliability. At the same time, modern monitoring solutions can help system operators to simulate lightning performance with real world data. Simulations tools can prove highly effective in optimizing any investment in LSAs.

Performance of EGLAs remains stable over time as opposed to experience with other methods such as improved grounding conditions. While individual monitoring of LSAs cannot be justified economically and remains complex, dedicated real-time monitoring solutions have been developed and offer convenient failure detection as well as other features such as fault localization and categorization.