All companies that operate overhead power lines, whether Transmission System Operators (TSO) or Distribution System Operator (DSO) share the common goal of working to optimize their inspection processes.

Achieving this goal has been difficult due to different protocols using different generations of inspection instruments whose data do not always correlate. Moreover, interpretation of data from the field has also relied heavily on skill of different operators and their ability to detect incipient problems. Conditions at time of inspection has also been a complicating factor since different results can sometimes be obtained based mostly on weather-related variables.

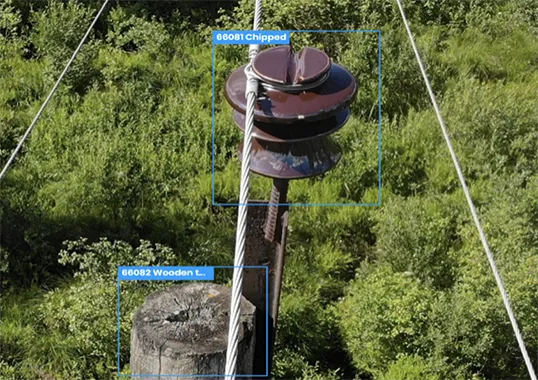

Fortunately, technology these days has allowed moving to a better option of inspecting networks using combinations of unmanned aerial vehicles (UAVs) and AI-powered software. The first milestone and objective in this transition has been to reduce manual labor required for digitalization and automating detection of defects from photos as much as possible without losing quality or inspection speed.

The end goal has been to detect defects that could cause problems in network operations, such as service outages or serious accidents. Ultimately, detecting defects before a failure will always be better than suffering service outages. In this regard, the benefit will always be cost savings since experiencing a service outage is typically much more expensive than repairing or replacing a faulty component before it fails.

There are also additional benefits of performing inspections with today’s generation of UAVs and AI-powered software. These include:

• Images provide better documentable information, traceability, and up-to-date data. This will reduce the inspection cycle for the network and allow better prioritization of maintenance work. It will also assist decisions to postpone asset end-of-life.

• High levels of inspection automation can be achieved using deep neural networks.

• Adding a digital fingerprint of all assets to the digital twin dataset.

There are also additional benefits of performing inspections with today’s generation of UAVs and AI-powered software. These include:

• Images provide better documentable information, traceability, and up-to-date data. This will reduce the inspection cycle for the network and allow better prioritization of maintenance work. It will also assist decisions to postpone asset end-of-life.

• High levels of inspection automation can be achieved using deep neural networks.

• Adding a digital fingerprint of all assets to the digital twin dataset.

Plan to attend the upcoming 2025 INMR WORLD CONGRESS, where expert Jorge Massardo of Hepta Insights will present the advances now made possible using UAVs and AI. He will also review case histories from across Latin America and elsewhere that help illustrate these advances.