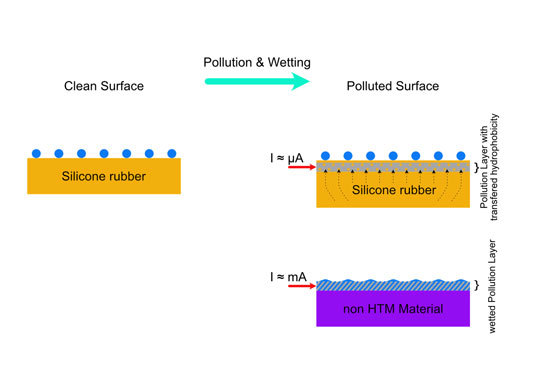

Hydrophobicity transfer materials (HTM) insulators, such as silicone polymer and room temperature vulcanizing (RTV) silicone rubber coated insulators, offer superior pollution withstand voltage performance due to hydrophobic surfaces. However, certain field experience from application of HTM insulators under heavy pollution indicates that loss of hydrophobicity and severe deterioration such as surface cracks and erosion of the housing material can occur, especially on the trunk portion, due to partial discharge and over only a relatively short period after installation.

Appropriately sized grading rings are equipped on the energized end (or at both ends of these insulators according to different system voltages) to protect the housing from damage due to electrical discharges caused by excessive local electric fields. While such e-field calculations are sometimes made only for dry and clean insulators, it is important to understand that distribution of e-field stress on insulators under polluted and wetted conditions will change significantly from that of dry condition.

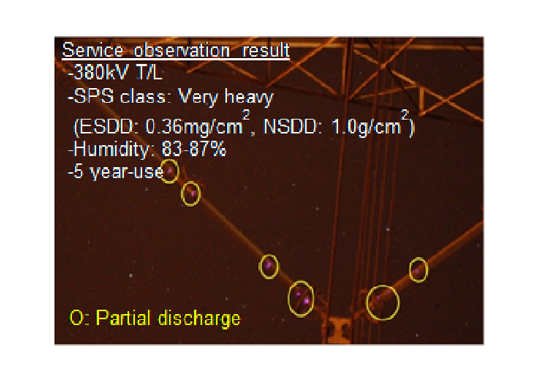

In fact, field observations under heavy pollution conditions have shown that partial discharges can occur anywhere along the length of an insulator and not only at both ends. For example, the location of loss of hydrophobicity, hardening and detection of nitric acid from the housing material has confirmed that partial discharges can also occur in the middle of insulators. This means that under such conditions grading ring(s) may not be effective in managing electric field. Selection of a rubber material that has superior nitric acid resistance is therefore important.

A nitric water immersion test to evaluate a housing material’s resistance to acid attack using a shorter and simpler procedure has been proposed to be included in relevant IEC specifications as a new accelerated ageing test method. During this investigation, rubber materials with superior acid resistance were developed not only by improving the ATH filler but also based on establishing the most appropriate balance among base polymer, silica and ATH filler.

Plan to participate in the upcoming 2023 INMR WORLD CONGRESS in Bangkok for a valuable technical presentation by Dr. Kuniaki Kondo describing how occurrence of partial discharges has been reproduced in a testing chamber. He will explain why application of grading rings and design of metal fittings are not necessarily the dominant factors in such applications and why it is also important to select materials with resistance to damage caused by partial discharge under polluted and wetted conditions.

[inline_ad_block]