Alternative insulator technologies have traditionally competed based on criteria such as performance and life cycle costs. These days, however, with the urgent need to combat climate change, another measure has emerged by which these technologies can be compared – which is the most sustainable in terms of net ecological impact. This edited contribution to INMR by Markku Ruokanen, R&D Director with PPC Insulators, argues that porcelain insulators are inherently the ‘green’ choice for T&D applications.

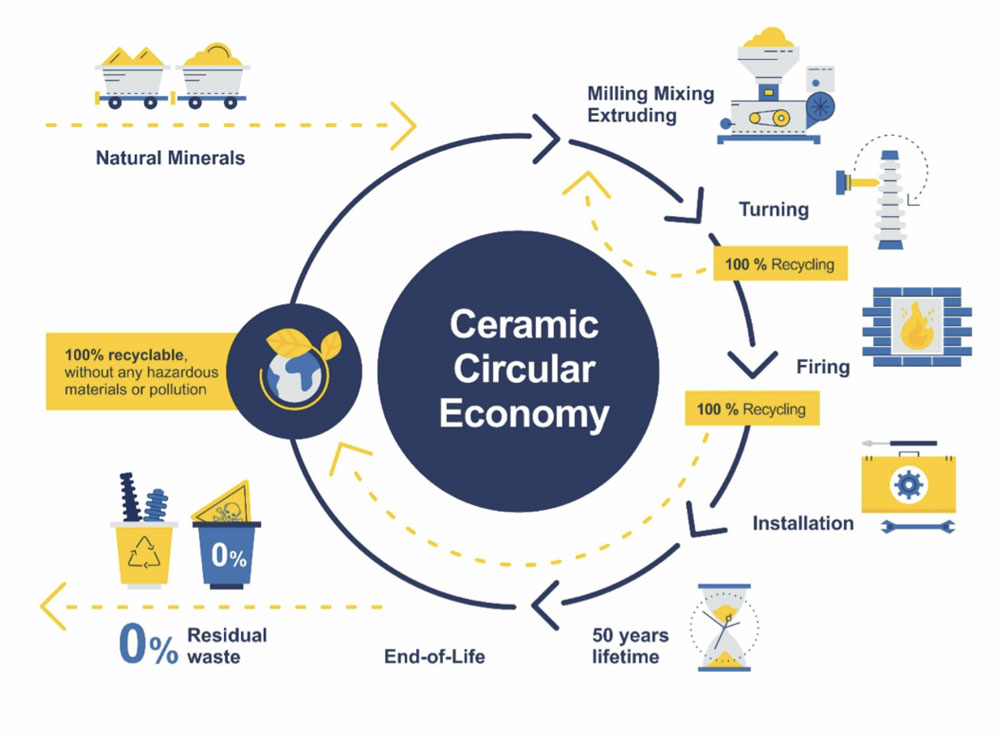

Although ceramics are among the oldest materials created by humans, modern C-130 porcelain insulators deserve to be called ‘hi-tech’ due to precise formulation of selected ingredients and advanced process controls. Ceramic insulators are also naturally ‘green’ in terms of low carbon footprint. This is because their basic raw materials such as kaolin, feldspar, bauxite and clays do not require complex refining and are also widely available. This allows use of local mining sources and reduced need for long transport logistics.

Once these raw materials are delivered to the insulator plant, they are mixed and milled according to desired formulation, extruded, shaped and then fired in a kiln at up to 1400°C. While this final step may seem energy intensive it does not mean that any energy is wasted. Today’s industrial kilns are a far leap from those once heated by wood or carbon and energy efficiency is their major design criterion. For example, tight gas-kilns feature advanced thermal insulating materials and coatings while heat exchangers are used to recapture energy from the process. Bio-methane as energy source is now also under review.

While the carbon dioxide equivalent of a ceramic insulator depends on manufacturer, factory, season and product mix, the Kyoto Agreement Scopes 1 and 2 values for porcelain vary between 1.0 and 2.0 kgCO2-eq/kg. Non-ceramic insulators, by contrast, are manufactured using components that have undergone different energy operations and with long logistics chains. As a result, it is estimated that their carbon dioxide equivalents can be several times that of ceramic materials.

When comparing carbon-dioxide equivalents, any analysis should also be based on total lifetime footprint, not only on Greenhouse Gas Protocol Scopes 1 and 2. GHGP Scope 3, for example, includes upstream and downstream carbon emissions. Here, impact of normal life expectancy and end-of-life treatment is also taken into account. This makes ceramic insulators even more ecologically friendly since their application covers over a century of field experience, with cases where porcelain insulators remained in service for up to 70 years until an upgrade was necessary. Indeed, ceramic insulators for substation and overhead line applications routinely have service lives of over 50 years, meaning dramatically reduced carbon footprint.

Finally comes the issue of end-of-life. Ceramic insulators are fully recyclable since the C-130 mass consists of aluminium oxide (50%), silicon dioxide (45%) and other metal oxides (5%). These naturally occurring minerals are non-hazardous as well as non-toxic, making recycling easy and cost effective. PPC Insulators, for example, recycles 100% of its porcelain production waste either internally in process or externally where it becomes a valued raw material for the construction and chemical industries. This also applies to insulators at their end-of-life.

In summary, while it is difficult to make an exact generic calculation of the total carbon footprint of any specific insulator, porcelain insulators are typically the ‘green’ option due to:

• natural, locally-sourced raw materials;

• long service lives;

• 100% recyclability with no hazard at end-of-life.

PPC Insulators is now working to offset its Scope 1 & 2 carbon emissions through compensation in partnership with ClimateCare and developing R&D initiatives toward the goal of zero carbon emissions by 2030.

References:

1. “Silicon Chemistry Carbon Balance” – 2019 Commissioned by Global Silicones Council

2. EPRI – IEEE Memphis, Jan 2013

3. “Testing Ageing of Porcelain Insulators” Ravi Gorur INMR

4. Cigré 2020, Paris, several papers

5. “Alumina Porcelain for High-Voltage Insulators” J. Liebermann, American Ceramic Society Bulletin Vo. 80, no 6

6. “Microstructure Based Evaluation of Field Aged and New Porcelain Suspension Insulators. A. Rawat and R. Gorur, Arizona State University

7. Wind Turbine Blades Can’t Be Recycled, So They’re Piling Up in Landfills, Bloomberg 05.02.2020