Coming at the 2025 INMR WORLD CONGRESS

Svenska kraftnät, the transmission system operator in Sweden, has about 200 substations at 220 and 400 kV, the majority of which have been built decades ago. A large number will therefore have to be refurbished or rebuilt in coming years. The ongoing energy transition is another factor promoting need for new stations due to change in demand. All this is creating the requirement to ensure continuous quality assurance during the process of large-scale building and refurbishment of substations.

Insulation Philosophy

For more than 20 years now, Svenska kraftnät has written in their technical specification that all apparatus insulation must be of composite material, except for earthing switches. The other exception is station post insulators which should be made of porcelain. As such, porcelain remains first choice for this application, although composite type posts might still be used should no other feasible technical solution be available.

A standardized substation in this network is built using two busbars and connecting transmission lines enter through gantry towers in the middle between them. Disconnecting breakers are used to separate the two busbars, one on each side of the gantry tower entry. This is the most common station layout, however, there are other designs as well. Station post insulators are used hanging from gantry towers or standing to support busbars as well as jumpers in the bays.

Composite Insulators

There was a gap period of some 7 years when the basic requirement by this TSO was that composite technology must be used for all new insulators within substations, including posts. No further requirements were stated. As a result, more than 1000 composite station post insulators were installed over this period and distributed among about 30 substations. The majority of these were not equipped with protective grading ring devices although, in some cases, these came installed on the insulators. It is planned that most of these composite posts are to be replaced with porcelain over the next 2 years, although some may remain in service during the technical service life of the substation.

Porcelain Insulators

Porcelain insulators are now the first choice when it comes to post insulators and Svenska kraftnät’s technical requirements for these include more than what is stated in IEC 60618. For example, there is the requirement for a corona free station and a grading ring is necessary to fulfil this requirement. There is also a requirement limiting the amount of quartz allowed in the porcelain.

Quality Issues

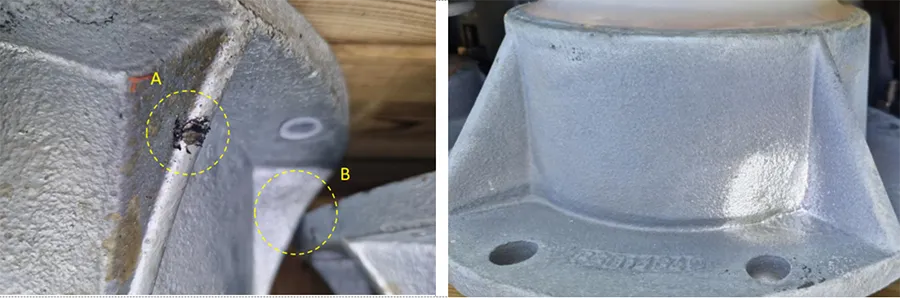

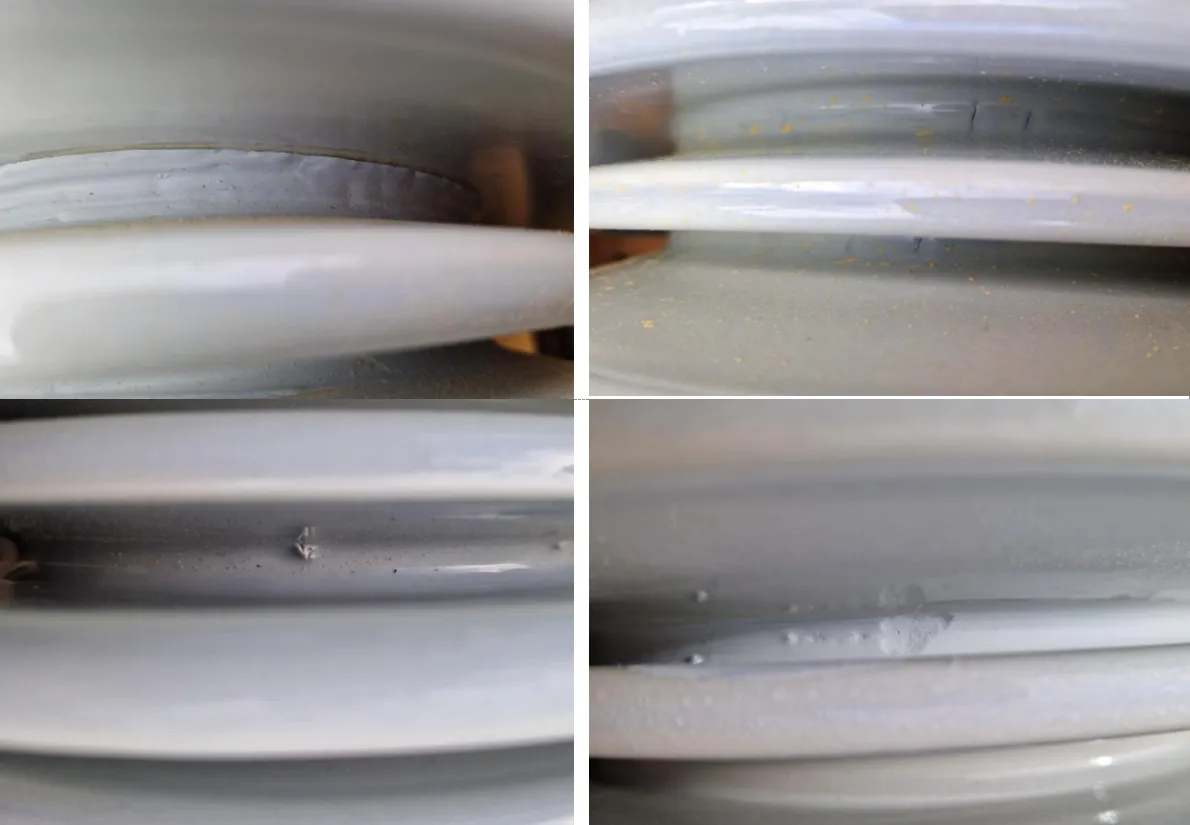

Many different quality issues have been found during service inspections within Swedish transmission substations. Many of these are not connected to the specific insulator technology (i.e. porcelain or composite) but rather to overall knowledge, quality control in design, manufacturing, handling and installation practices. Moreover, there were a range of different findings during quality control either at the construction site or during factory acceptance testing at the manufacturer.

Plan to participate at the 2025 INMR WORLD CONGRESS in Panama. Insulator expert, Peter Sidenvall of the Independent Insulation Group will present findings detailing a range of quality issues identified during close-up inspection of station post insulators both on site and in the factory. In a separate presentation, he will also make valuable recommendations on processes and procedures to perform condition assessment during service inspection of composite insulators at substations.