Background

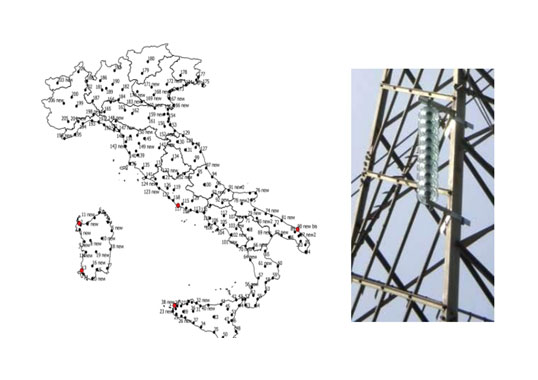

Polymer insulation technology was initially developed in the mid-1940s for indoor electrical applications. These early polymer insulators, while effective in controlled environments, encountered significant performance challenges when exposed to outdoor conditions such as UV radiation, moisture, and pollution. Through iterative development and field testing, the first successful outdoor applications emerged in the early 1960s, primarily on distribution lines.

By the 1970s, polymer insulators had evolved sufficiently to be deployed in outdoor transmission systems. The first-generation polymer insulators introduced in the 1980s were typically specialty designs, targeted for use in environments where traditional ceramic insulators exhibited performance limitations, particularly in areas with high contamination or severe weathering. Vandalism was also a key factor in the early adoption of polymer technology. These early designs laid the groundwork for the advanced polymer technologies in use today.

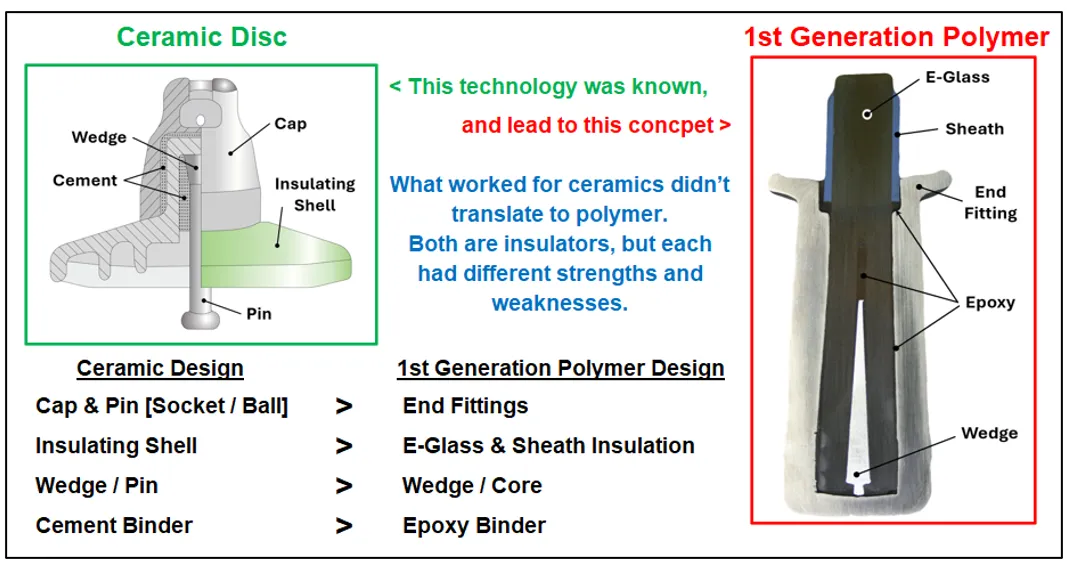

Development of first-generation polymer insulators marked a significant shift in transmission line technology, though it was accompanied by a steep learning curve. These early designs were heavily influenced by the principles and practices established for ceramic disc insulators, which limited their initial performance and reliability. Despite these challenges, certain first-generation polymer insulators demonstrated robust performance, including successful applications at Extra High Voltage (EHV) levels.

Knowledge Gaps & Design Limitations

Initial development of polymer insulators was hindered by a limited understanding of polymer behavior in high voltage outdoor environments. Early designs were heavily influenced by ceramic insulator design and standards, which did not translate effectively to polymer insulators. While both materials serve as insulators, they exhibit fundamentally different mechanical, electrical, and aging characteristics. This variance led to less effective performance and a steep industry-wide learning curve for both suppliers and users.

Material & Manufacturing Challenges

Early polymer insulators utilized a variety of different housing materials, including:

• EPDM (Ethylene Propylene Diene Monomer)

• Silicone Rubber (HTV & LSR)

• Material Alloys and Blends

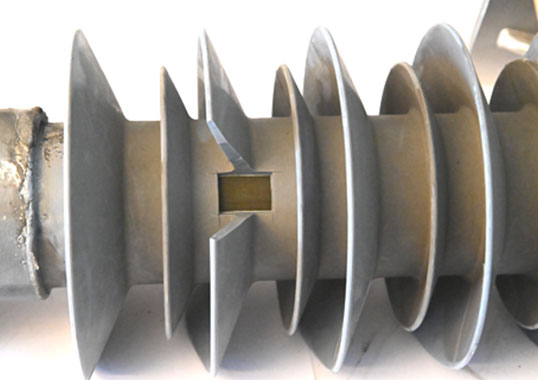

Housing application methods varied and included molded, extruded, and slip-on techniques. Notably, bonding between the housing and the fiberglass core rod was not initially required, which contributed to moisture ingress and interface degradation.

Other key characteristics of early designs included:

• Sheath Thickness: early generation designs used 1.5mm sheath thickness;

• Use of standard E-glass rods containing boron oxide, which are susceptible to brittle-fracture (BF) under stress corrosion;

• Wedge – epoxy-potted end fitting attachment lacked mechanical strength and reliability;

• Minimal or no sealing at interfaces, increasing vulnerability to environmental contamination and moisture penetration.

Application-Specific Limitations

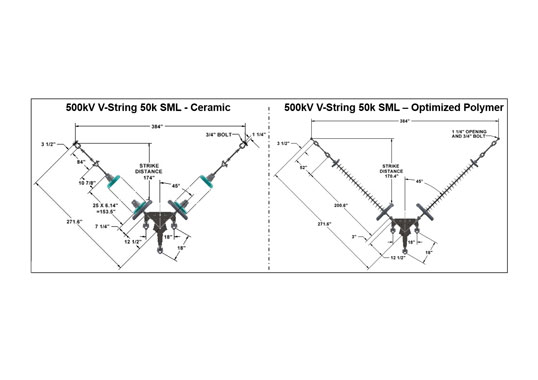

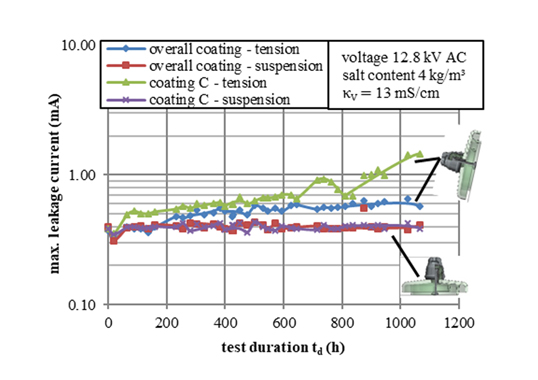

When applied in the field, early polymer insulators were often used as direct section length replacements for ceramic strings. This approach resulted in under-insulation, which led to performance issues:

• Reduced dry arc distance: Typically, 15-20% shorter than equivalent ceramic strings, often resulting in two to three fewer discs of insulation.

• Leakage distance: Often equal to or less than that of ceramic equivalents, limiting performance in polluted environments.

• Corona Protection: Rarely applied in early designs (less than 345 kV) due to limited understanding of its impact; lack of grading devices led to localized electric field stress, accelerating material degradation and failure.

• Brittle fracture: The most common historical failure mode of polymer insulators, due to stress corrosion of the fiberglass core and inadequate sealing.

Plan to attend the upcoming 2025 INMR WORLD CONGRESS in Panama, where insulator expert Ed Niedospial of MacLean Power Systems will review the major advancements in polymeric materials, housing application, seal reliability, and manufacturing efficiencies over the past 30 years. He will then explain how these improvements have led to enhanced mechanical strength, superior hydrophobicity, improved resistance to environmental degradation, and longer service life. Finally, he will provide guidance on how these technological enhancements can be integrated into modern EHV system designs.