Coming at the 2025 INMR WORLD CONGRESS

Prior to 1970, the specific creepage distances of insulators specified by the South African national utility, Eskom, were low and at transmission levels were suitable only in light pollution severity environments. Subsequently, frequent flashovers were experienced, and large-scale washing and silicone greasing programs were introduced, both for overhead lines and substation insulation. For example, on two critical 275 kV lines feeding a large aluminium smelting works, standard glass disc strings were replaced with long rod porcelain of higher creepage distance. Still, outages continued and costly, continuous helicopter spray washing had to be undertaken.

With introduction of polymeric insulators, epoxy resin long rods were later installed. These failed within two years when suspension units flashed internally and strain units suffered from brittle fracture of their cores. Finally, the problem was resolved with installation of silicone rubber composite long rods.

In the early 1990s, success in using the silicone rubber units here and elsewhere, prompted applying these to replace glass strings in many polluted areas. For new lines, more cost-effective designs were produced which utilized the high strength-to-weight ratios of silicone composites.

In substations, however, given many different posts, bushings and equipment housings, general insulation replacement is not feasible. Washing insulators can be effective but must be done frequently. Moreover, timing of cleaning is difficult to judge. Often, flashovers are experienced when fogs, mists or rains occur unexpectedly. Further, in areas subject to periodic ‘instantaneous’ pollution events, washing offers little benefit.

Application of silicone grease, with its water-repellent properties and ability to encapsulate contaminants, allow for a longer maintenance interval than washing. But the labour intensive and costly task of replacing grease on a regular basis, makes this a relatively unattractive remediation option. Other drawbacks of greasing include long associated outages required, possible insulator flashover or damage if the layer is not renewed in time, health risks and environmental disposal problems.

Given the above as well as the performance of silicone rubber insulators on overhead lines, application of silicone rubber coatings has become the standard for insulation enhancement at both new and existing substations in polluted areas.

Benefits of Silicone Rubber Insulation Materials

Silicone rubber, with its high surface hydrophobicity, prevents formation of a continuous, wet conductive layer on insulation surfaces, thus inhibiting flow of leakage currents and consequent flashovers. Moreover, silicone has the unique property of allowing low molecular weight silanes within the bulk material to diffuse into the surface pollution making the contamination layer hydrophobic itself. This allows protection even in environments of high-volume pollutants, such as sea sand and cement dust, or where ‘instantaneous’ pollution in the form of marine salt fogs and sulphurous industrial emissions can occur.

The material has a high dielectric strength, is resistant to damage from most chemicals and the Si-O bond forming the backbone of the polymer is strong enough to withstand solar UV radiation without breakage. Fillers are included to protect against erosion due to leakage current.

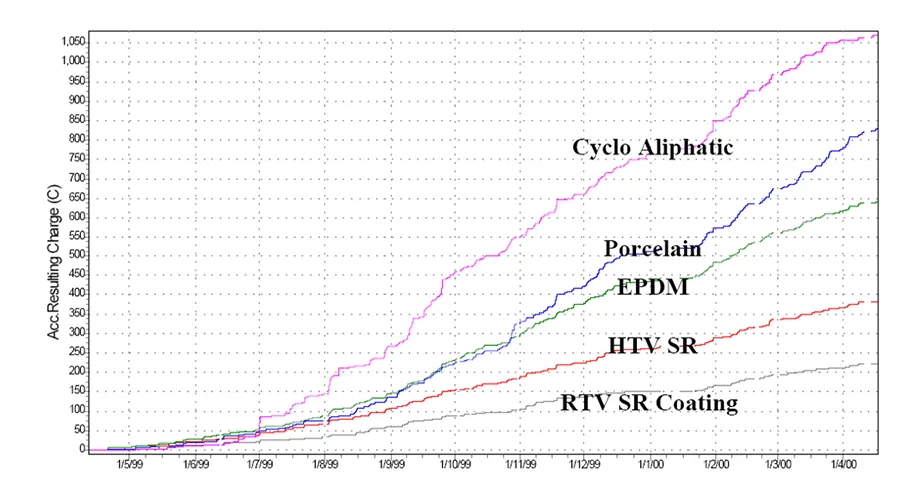

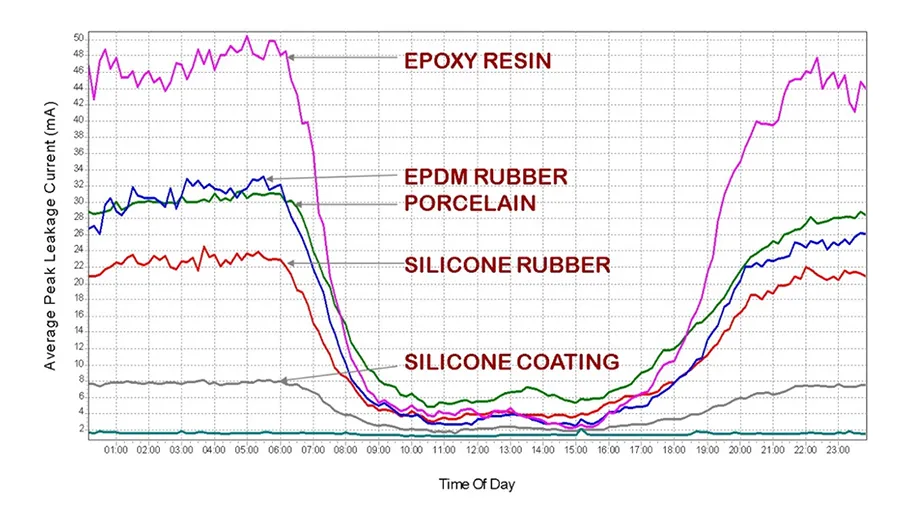

Evaluation of the relative performance of a variety of insulator materials was conducted at the Koeberg Insulator Pollution Test Station located on the west coast of South Africa. The test insulators for all the materials were manufactured to identical dimensions to exclude any other variables such as diameter, shed profile and creepage distance. The test duration was 1 year during which the leakage currents flowing on each insulator were continuously monitored. The results are illustrated in Figs. 4 and 5 below. With reference to Fig. 4, it is shown that the cumulative leakage current on the RTV silicone rubber coated porcelain specimen was the lowest – only 27% of that of the uncoated porcelain unit and 56% of that of the silicone rubber composite. Fig. 5 indicates the average peak hourly leakage current amplitudes recorded. The highest daily values were 8 mA on the coated insulator compared to 24 mA for the silicone rubber composite and 31 mA for the uncoated porcelain.

Plan to attend the upcoming 2025 INMR WORLD CONGRESS in Panama. Recipient of the Claude de Tourreil Memorial Award for Lifetime Achievement in Insulators, Roy Macey, will review the important lessons learned from 30 years of applying RTV silicone coatings in South Africa and elsewhere. His insight and experience will assist users to avoid common problems and achieve optimal coating service life and performance.