Introduction

IEC60383-1 [1] has not been revised since its fourth edition was released in 1993. The name of the standard is “Insulators for overhead lines with a nominal voltage above 1000 V, part 1: Ceramic of glass insulators for a.c. systems – definitions, test methods and acceptance criteria”. The standard deals with four different types of insulators:

• Pin insulators

• Line post insulators

• String insulator units

• Insulators for overhead electric traction lines

The standard has been stable and has been frequently used and referred to. However, in the last few years there has been an increase in requests for non standardised tests based on user specific requirements (environment, system, etc) or the fact that the standard is not up to date and need to be revised and adapted to more stringent conditions. IEC60383-1 has not been revised since it has been deemed to meet the expectations of the market needs. However, in the last ten years there have been a number of publications [2, 3] stating the need for updating the standard. The main reason for this is that it has been seen that the tests are not stringent enough to fulfil the requirements of the transmission system operators (TSO). Different types of failures have been seen in service leading to development of tougher requirements (e.g. increased test duration, increased number of samples etc.) and new test methods.

In 2016 it was decided at the TC36 plenary meeting in Frankfurt to start the revision of this standard. The revision was assigned to a new maintenance team (MT20) and since then MT20 has been working intensely to revise the standard. A CD is planned to be distributed to the national committees at the end of 2019. The aim is to publish the new revision at the end of 2020.

This report summarises the work done within IEC TC36 MT20 up until summer 2019. An update of the ongoing work will be shown in the presentation.

As the work is ongoing the final content and exact wording still remains to be decided by MT20 and the national committees of the participating countries.

Layout of the Standard

The current version of the standard is based on the layout as when it was written in early 90’ies. It is a well written standard with many tests, electrical, mechanical and material. The procedure for sampling is based on ISO-standards such as ISO2859-0, -1 and -2.

The current layout is not in accordance to the current form and rules of IEC and the complete document is therefore revised. Changing format and layout is a major revision and the MT has had long and good discussions on how to improve the standard and the layout of it.

Several chapters in the old version have been removed or heavily reduced. Examples are Quality assurance, standard atmospheric conditions, etc. At the time when this standard was written it is fair to assume that not all information was available and therefore it was included in this standard. The standards referred to are today well developed and mature thus it is no longer necessary to include this information in the new version.

Another major change in the layout of the standard is that the cross reference tables which specify which type of tests (type, sample, routine) are valid for a specific type of insulator and the number of samples to be tested has been moved from the end to the beginning of the document. The MT feels that the cross reference tables are the most vital part of this document and that the tables should therefore be as early as possible in the document.

Proposed Revision of Existing Test Methods

In the verification of the locking system, the acceptance criterion for the operation test has been adopted to handle split-pins and W-clips of loads up to 650 N.

In the porosity test there is a discussion regarding with dye penetrant to use and as proposed now it will be Astrazon that is specified. There is an ongoing discussion in other IEC groups on how to specify dye penetrant and how the results are affected by it.

For routine visual inspection it is discussed to add more information regarding surface defects particularly in glass insulators.

New Test Methods Discussed

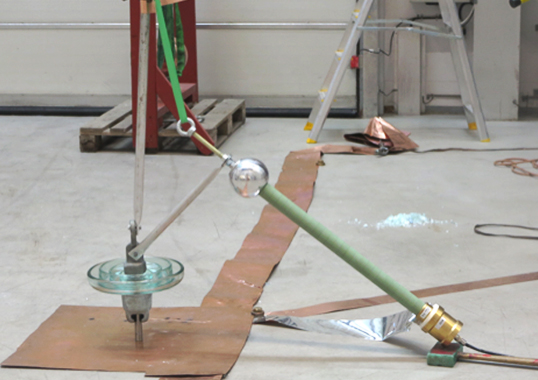

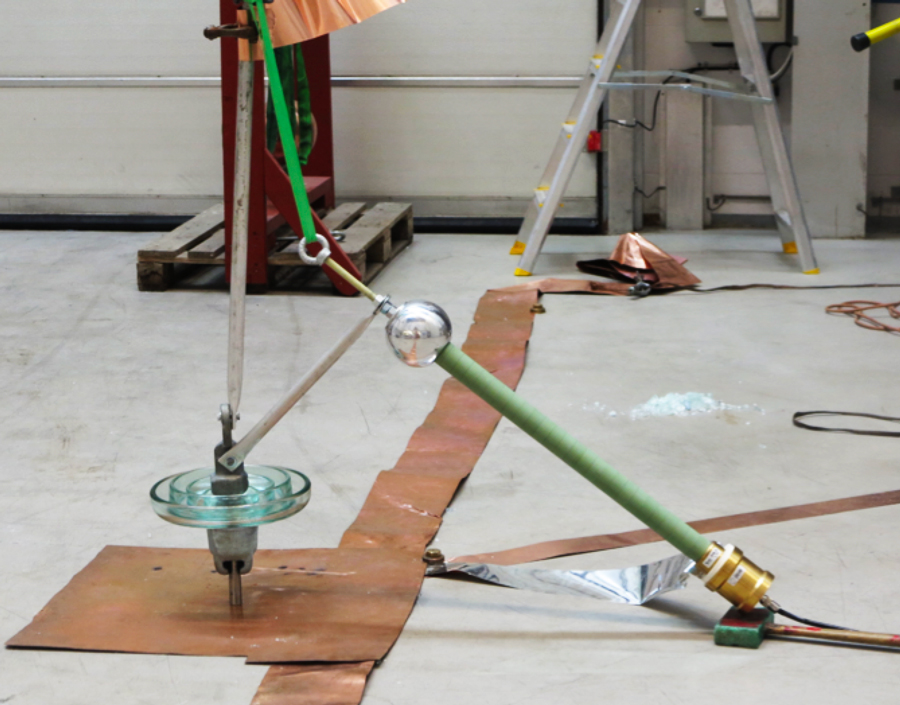

Impulse Puncture Test in Air (steep front)

As it is discussed the new IEC60383-1 will contain reference to two different methods for evaluating puncture withstand. The puncture test may be either an impulse puncture withstand test or a power-frequency puncture withstand test. This test is performed to evaluate the puncture strength of the insulator, which depends on both the design and quality of manufacturing.

The section regarding power frequency puncture withstand test remains more or less unchanged. An additional section has been added specifying the impulse puncture withstand test based on IEC61211 which is shortly described below (see figure 2). Also a similar discussion is ongoing within ANSI as the standard ANSI C29.2B is being revised.

The test set-up, test voltage generation, measuring equipment and test procedure shall be according to IEC 61211. The number of insulators to be tested shall in accordance with tables in IEC60383-1 but the exact number is still under discussion. The insulators to be tested shall be dry and clean.

The test shall be performed on each unit where a series of five positive, five negative, five positive and five negative impulses shall be applied (in this order), with a time interval of 1 minutes to 2 minutes between consecutive impulses of the same polarity. No impulses with reduced amplitude shall be applied between the polarity changes.

Puncture Determination and Acceptance Criteria

An insulator passes the test if every steep-front impulse voltage application results in an external flashover, and the test record or peak voltage indicator does not show any marked reduction in voltage between impulse applications;

For the evaluation of the results from the tested batch it is recommend to apply the acceptance criteria in accordance with IEC 61211, cl 5.8, requiring that no punctures are accepted and if only one unit is punctured a re-test procedure shall be applied. In addition it is proposed that part of the tested insulators go through the mechanical failing load test in IEC 60383-1 Also punctured units shall be included.

Mechanical Failing Load Test after Impulse Test

As mentioned above, it is proposed and discussed that a number of insulators that have been tested in the impulse puncture test, e.g. 5 samples, should also be evaluated in the mechanical failing load test. The test should be done in order to ensure that the mechanical properties have not been lost due to the electrical test.

RIV Test

RIV test has been added and shall be performed on single insulator units. The test circuit and equipment shall be according to IEC 60437 and CISPR. The acceptance criterion is still under discussion. The discussions are whether or not a specific level should be set based on line voltage or if a statistical approach should be used.

Zinc Sleeve Test

A section has been added specifying the zinc sleeve test. The test is to be used whenever applicable. It refers to IEC61325. A re-test procedure has been adopted in case of failure to fulfil the acceptance criteria.

Impact test

Another test under discussion is the impact test. This is a test that is required by many TSOs and also included in some regional and national standards. However, the test procedure, test equipment and the acceptance criteria need to be evaluated and discussed further. In principal the test is performed by hitting the outer rim of the shell squarely in a direction parallel to the axis of the cap and pin insulator with a specific force.

An acceptance criterion can be that the insulating body of the insulator cannot rupture below a certain level. Also the release of splinters during the impact test is considered as partial disruption of the insulating body and, in this case, the result is considered not satisfactory.

RTV-Coatings

At the TC36 meeting in Busan 2018 it was decided to include an annex on RTV-coatings and requirements that are specific for this type of product. The annex is under development and will contain some general information and some additional tests to be performed. Tests that are specific for polymeric insulators are most likely to be specified in this annex. Test can be e.g. adhesion, tracking and erosion etc.

Summary

MT20 was in 2016 assigned with the task to revise the standard. The first meeting of the MT was in September 2017 and by the end of 2019 the first CD will be circulated with the IEC national committees for comments. There will be substantial changes in the layout, partly because the old layout do not follow the current IEC layout and partly to increase the readability of the document. The current test methods have been reviewed and updated when deemed necessary. In addition there are a number of new test methods proposed in order to in.

References

1. IEC60383-1, 1993

2. Proposals for additions to IEC requirements intended to verify quality of glass cap and pin insulators, K. Halsan, I. Gutman, J. Lundengård, L. Carlshem, J. Velek, T. Condon, P. Shiel, J. Lachman, R.W.S. Garcia, B2.311, CIGRÉ 2016, Paris, France

3. Impact of quality of glass cap-and-pin insulators on life cycle costs and proposals for screening tests, K. Halsan, I. Gutman, J. Lundengård, L. Carlshem, J. Velek, K. Välimaa, J. Lachman, B2.209, CIGRÉ 2014, Paris, France.</span