Condition assessment of electrical insulation systems plays a key role in asset management these days. As a result, electricity supply companies throughout the world look with interest for any improvements in the way such information can be obtained. On top of this, there is basically constant attention being devoted to such issues as cost reduction and lower environmental impact as well as the introduction of new materials to make these possible. This edited past contribution to INMR by retired Prof. Stanislaw Gubanski of Chalmers University of Technology in Sweden, explained why these issues call for improved diagnostic techniques capable of providing the desired information quickly and cost effectively. In this respect, application of dielectric response measurements, in both time and frequency domains, to characterize the quality of insulation systems has become increasingly attractive.

The idea of utilizing dielectric measurements to determine properties of materials is certainly not new. In fact, the transient response of materials due to the sudden application of voltage has been studied since the beginning of the last century. This methodology has been used by chemists and physicists alike to characterize the time dependent response of various substances so as to better understand their nature and chemical structure.

Perhaps most famous in this regard was the work of Peter Debye, a scientist who as far back as the 1920s had contributed significantly to formulating a theory of electric polarization of dielectrics. Since then, the dielectric response of different insulating media has often been described in terms of so called ‘Debye relaxation time distribution’.

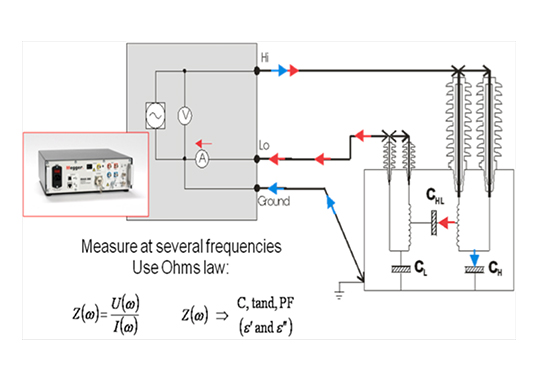

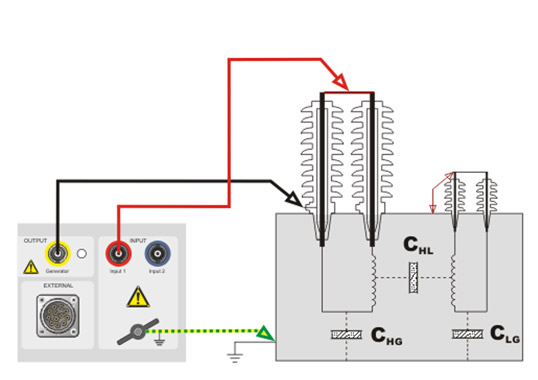

In short, the principle of dielectric response is as follows: when an insulation medium (whether solid, liquid, gas or combination thereof) is exposed to the excitation of electric stress of any arbitrary time-varying form, it responds by polarizing electrically. The way this proceeds over time can be described by means of the dielectric response function, which is proportional to the externally measured current.

In the frequency domain, this response is characterized instead by the frequency-dependent complex dielectric permittivity, where its real part is proportional to the material’s capacitance and the imaginary part to its losses. There is clearly a direct and clear mathematical coupling between these two representations. In other words, dielectric response can be considered as a material’s (or whole insulation system’s) basic fingerprint, which then varies whenever its properties change due to e.g. ageing, water intake or any other type of degradation. Dielectric behavior in the low frequency (long time) range is especially sensitive to such changes.

Most engineering professionals are already familiar with simplified forms of dielectric response measurement. The measurement of capacitance and dielectric loss (i.e. tan delta) at 50/60 Hz, for example, has been used as a standard in testing insulation for many years now. The same applies to measurement of insulation resistance (IR) and polarization index (PI). Because of their simplicity, past experience and high level of international recognition, both these measurements are still often being used. Nevertheless, they provide comparatively little information about the actual condition of insulation since they are limited to single value results.

It happens, however, that insulation systems with different degrees of ageing and/or degradation usually exhibit similar levels of dielectric losses under power frequency, with these differences being more clearly exhibited at the lower frequency range. To overcome this drawback, measurement of dielectric response characteristics across wide bands of frequency or time have been proposed since they will provide that much more information on the insulation system. Typically, the range between 10-4 and 103 Hz is used in frequency domain measurements while a measurement duration of between a few seconds and a few hours applies for the time domain.

Until the 1970s, relatively little attention was given to automated measurement techniques of dielectric response. But this situation changed over the ensuing two decades thanks to development of more powerful computing and rapid signal acquisition and data analysis. The first field instruments for dielectric response measurement, for example, were introduced by the mid 1990s. These contributed to a major breakthrough in the versatile use of this technique to diagnose insulation systems in transformers, electrical machines, bushings, cables and cable accessories. In particular, the application of this methodology to estimate dryness of the oil-paper insulation in power transformers has been broadly recognized.

Several publications are presently available on this topic. In addition, CIGRE Study Committee A2 (Transformers) dedicated several years of work to assessing the reliability of dielectric response measurements. This resulted in two technical brochures being issued (No. 254 and No. 414), which advise how to use this technique and best interpret the results. It’s also worth noting that robust dielectric response measuring equipment is currently available on the market from different suppliers. Such systems also provide built-in reliable schemes for interpreting findings.

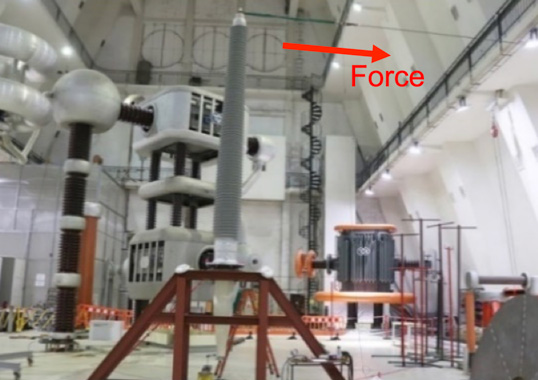

The experience in regard to dielectric response measurement when it comes to bushings has so far been more limited. But since the ageing of bushing insulation is a growing concern worldwide, the search for a more robust test methodology than provided by 50/60 Hz tan delta measurement has been ongoing.

Bushing condition diagnostics based on average temperature correction tables have proven mostly disappointing. However, this can now be reliably replaced by a superior methodology based on frequency response measurement. One of the principal advantages of this approach is that it provides for the possibility to perform individual correction of dissipation factor at every different bushing temperature.

[inline_ad_block]