The requirement for more reliable and cost effective power networks continues, with downtime measured (and penalized) in minutes as well as seconds. Over the past 20 years, there has been increasing realization that the uncontrollable external impact of wildlife is responsible for a far greater proportion of unplanned outages than previously acknowledged. As a result, wildlife and asset protection has become an area of growing interest given that reducing unplanned outages equates to improved efficiency. Consider, for example:

• The cost of even a single outage can prove extremely high;

• Potential fines for not adequately protecting protected wildlife are increasing;

• Estimates of wildlife outages/year have typically been in the tens of thousands and the global cost of such outages has been estimated at over US$10 bln/year;

• 50% of wildlife-induced outages are caused by birds.

Along with better understanding of these challenges has come added pressure from environmental organizations and these concerns now mesh with those of electricity suppliers where reliability is the critical factor.

This edited past contribution to INMR by experts at TE Connectivity dealt with applications where wildlife can interact with electrical networks

Every power provider has suffered periodic disruptions from unplanned outages of one type or other. These have traditionally been classified as Weather, Wildlife or Unknown, with limited knowledge of the proportions due to each. Now, with greater knowledge, such unplanned outages are better categorized as due to:

1. Wildlife (birds & animals)

2. Weather (storms, wind, lightning)

3. Vegetation (tree branches)

4. Human intervention (accidental or deliberate)

5. Unknown or not yet categorized

Broadly speaking, problems created by wildlife at substations and on overhead lines fall into one of two main categories: bridging and wildlife guano pollution flashover. While the result – a system trip and possible arc flashover – may be the same, the way it was brought about and the best solution differs in each case. So do the remedial products that can be applied to the equipment being compromised.

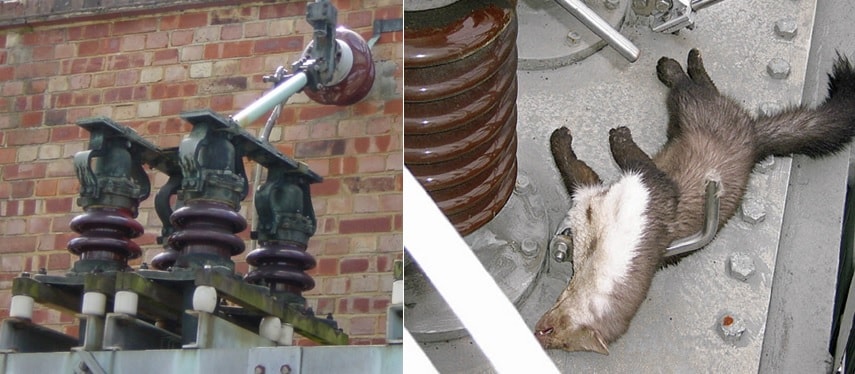

Bridging is where a bird or animal makes contact between phases or between phase and ground, leading to a short circuit. For example, large birds can easily cause problems across all distribution voltages at substations and on lines. Phase bridging usually results in the creature being electrocuted and how it falls will determine whether the auto-reclosing system operates successfully or not. Often the bird or animal will fall away and allow the auto-recloser to re-energize the circuit. Although this may not normally require investigation by emergency crews, it usually leaves unnoticed but tell-tale evidence of damage.

Although the circuit may operate normally, a series of such events can lead to progressive damage that becomes worse with each successive trip and that finally causes hardware failure, e.g. where each trip burns out a single strand of conductor eventually dropping the line. Moreover, if the dead creature falls between its points of contact and remains there, this will result in the circuit not being able to be re-energized until an emergency crew removes the fault source. At least, this type of event can be logged with some certainty of what happened. By contrast, when the bird or animal falls to the ground or on top of a transformer, it is likely to be removed by a predator and no evidence will remain.

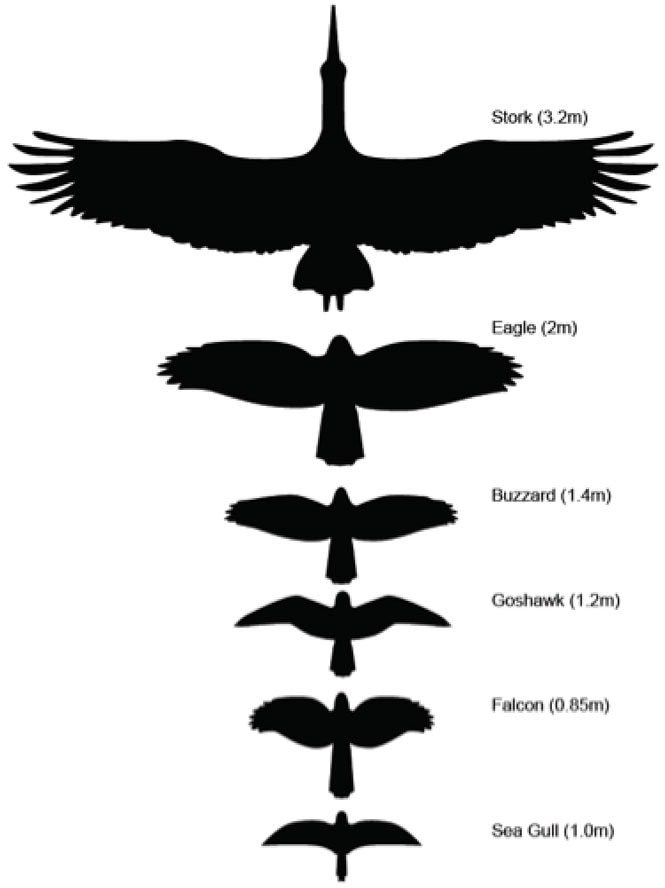

Most bridging problems occur on MV systems (typically < 36 kV) designed such that bare conductors, bushings, busbar systems and other equipment have ‘air-spaced’ clearances that operate without issue under normal conditions. Clearances are typically up to 40 cm at substations and about 1m for overhead lines to allow for swinging conductors. Unfortunately, these clearances mean that a wide range of birds and animals can cause problems at substations and on lines. It should be noted that, although line conductors are generally 1 m apart, the most common failure mode is between the cross-arm (usually grounded) and the conductor – a typical clearance of only 30 to 40 cm.

Medium and large birds perch on a cross-arm and bridging usually occurs during landing or take-off. In more unusual cases, depending on location, wildlife such as bears, possums or even snakes climb poles and cause similar problems.

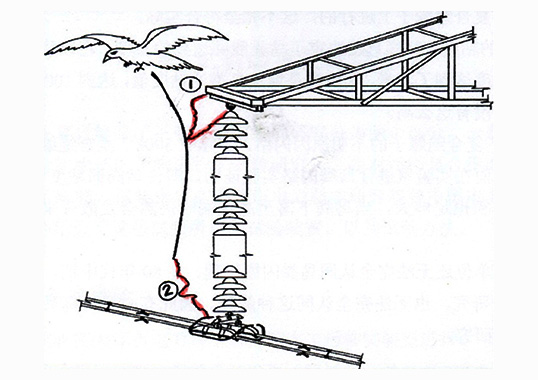

Pollution flashover from bird guano is a less frequent occurrence but can be every bit as damaging as bridging-induced outages. It is mostly associated with line insulators but can also occur at substations and differs from bridging since it can happen across all voltages – even up to EHV. Such flashovers of bushings or insulators results from build up of guano for weeks or months during dry conditions when there is no rain to wash it away. Birds often favour certain places to perch and this is often the extremity of a lattice tower arm, directly above the insulator string. While the build-up of guano can be considerable, as long as conditions are hot and dry the relatively small individual amounts of liquid guano dry quickly and surface resistance is not greatly altered.

Flashovers take place when mist, fog or rain returns, changing the dried guano into a semi-liquid state and greatly reducing surface resistance of the porcelain or glass insulator. If the build-up is sufficient to alter the conductivity of the insulator string, flashover can result. It should also be noted that another bird related failure mechanism – guano streamers –can cause flashover when a bird perched above an energized conductor emits a liquid streamer up to 2 m that effectively shorts out the otherwise safe air gap.

While all countries see some level of wildlife induced disruptions, the diverse nature of the particular birds or animals causing the problem as well as the different types of equipment and service conditions mean that the optimal approach to prevention also differs on a case-by-case basis. Once a failure mechanism is recognized, the latest generation of materials and designs make it largely preventable, often for the entire remaining life of the equipment.

Diverse Problems Across the Globe

The range of wildlife problems experienced by substation and overhead line engineers is too vast to cover in one article so common examples discussed below give a flavour of the diverse issues that can be encountered. Wildlife problems affecting power networks are categorized as ‘migratory related’, ‘local specific’, ‘food-related’ (predator or prey), ‘shelter/security/nesting related’, ‘seasonal’ and ‘other’.

Migratory issues relate only to birds passing through one area en route to a final destination in order to feed and rest. These short time periods can cause local havoc by overcrowding mast tops where there is limited perch space available. In such cases, there is high risk of bridging phase-to-ground or phase-to-phase clearances. Other incidents include birds flying into lines near feeding sites, usually at distribution voltages where conductor clearances are such that large birds colliding with them can bring two conductors together, resulting in flashover. Once birds have completed their migration, they tend to return to the same location year after year. This means that, even if old nests are removed once the birds have left, they will be rebuilt the following year on that precise pole or tower.

The exact nature of any failure will depend on the design of affected equipment, type of bird involved, system voltage etc. but can be as simple as bridging while the bird is perching on a MV cross-arm. Guano induced failures most often impact HV suspension towers. Similar problems can arise from materials falling out of nests or when groups of birds fly in and around jumpers where there is a switch or pole top transformer.

Absolute data regarding the number of birds killed worldwide from interaction with power networks is usually under-reported since many countries do not record such statistics or fear their publication due to possible regulatory consequences. From data that does exist, however, it is clear that a figure measured in tens of millions of birds killed each year is beyond question. Seen from the viewpoint of electricity suppliers, this massive loss of wildlife equates to annual losses of over US$10 bln from lost revenues, damaged equipment, emergency call-outs by line crews and fines imposed by regulatory authorities. Some countries use legislation to protect endangered wildlife with severe penalties of up to US$ 500K.

Problems at substations are almost exclusively of a bridging nature when birds or animals bridge phases or phase-to-ground. Issues are generally not migratory related but can be seasonal, e.g. during cold weather when cats and similar size creatures are attracted to warmth close to a transformer. This seasonal problem can also be due to small birds building nests that attract a range of predators such as cats, snakes, larger birds or other species.

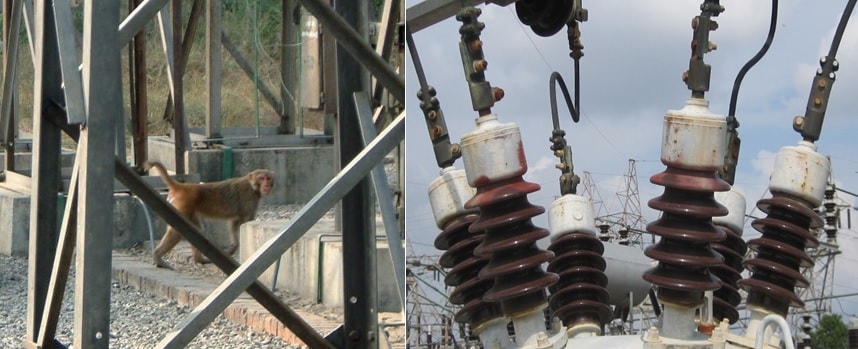

At MV substations, the ‘rule of thumb’ is that anything up to a maximum of 40 cm between phases or phase-to- ground is considered vulnerable to bridging by wildlife. This critical distance can be a greater (even up to 1 m) if a substation is plagued by wildlife such as snakes, monkeys and large birds of prey.

Solutions to Prevent Wildlife Outages

Given the huge financial costs, loss of wildlife and inconvenience to the public, it is a surprising that almost all the problems due to direct bird or animal interaction with power networks were preventable. The best solution to such problems is generally one that allows whatever wildlife is involved to safely access their chosen sites without causing electrical breakdown of any part of the system. It is equally important that any solution be cost effective such that the costs of installation are considerably less than the cost of the possible outages to be avoided.

It is still not possible to put a cost to avoiding every potential wildlife problem because of the diversity of issues and creatures. Still, it is estimated that it can vary from as little as US$ 1 K to in excess of US$ 1mln. An average of circa US$ 10 K is used in the U.S., where the majority of such data originates.

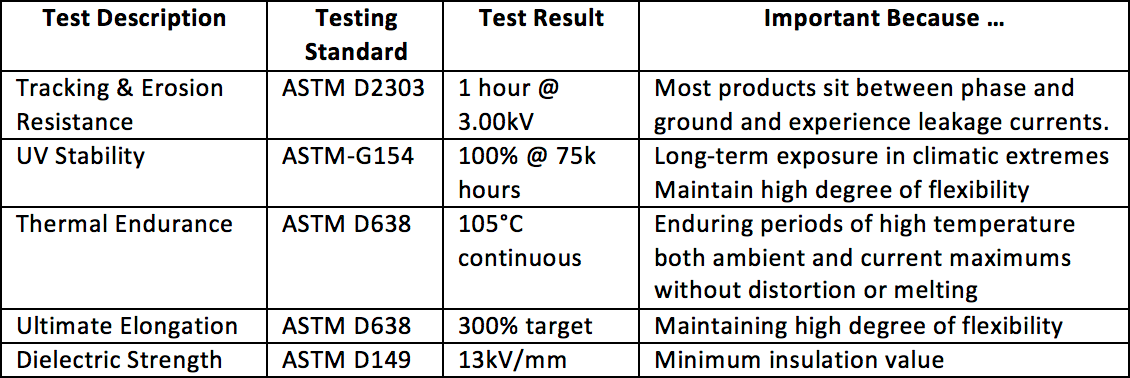

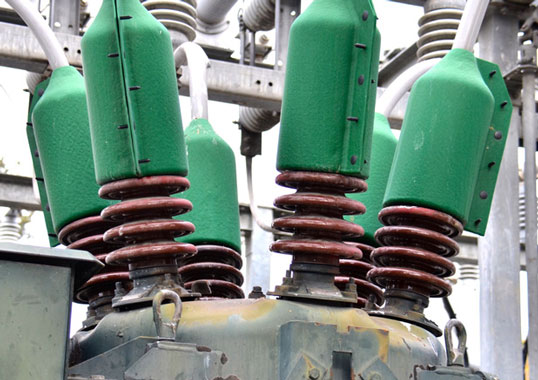

The importance of the protective material used cannot be overestimated. This is because any solution to a wildlife problem must not cause issues downstream because of material failure. On ‘day one’ almost any solution will perform to some degree; but the most effective solution will continue to work maintenance-free for the life of the equipment on which it is installed. This will often mean at least 20 years or longer in challenging environments such as extremes of hot and cold, severe weather, long-term exposure to UV as well as a variety of pollutants, especially uric acid (the main chemical in bird guano). With these environments in mind, materials need to exhibit a minimum of technical criteria according to the relevant international standards, as shown in the Table below:

In addition to optimized geometry, materials used must deliver consistent performance, without electrical or mechanical breakdown, for over 30 years. As such, these materials have to be robust mechanically, maintain excellent electrical properties while remaining tolerant to wildlife exposure. The photos below illustrate what can happen in a short time when minimum levels of such performance are not met.

A variety of alternatives have been tried over the past 20 years, including sonic deterrents, barriers, covers, electrified fences, smooth climbing barriers, chemical barriers and spined perching devices designed to drive the bird or animal away from a specific location. However, in most cases, the problems only re-surface elsewhere. There is also the consideration that migratory birds in particular and even some resident animals always return to the same nest or feeding sites. This reinforces the importance of finding a solution to protect the reliability of electricity supply while also allowing wildlife unhindered access.

Many of the wildlife protective solutions adopted over the years have brought some limited, short-term or localized benefits. But experience has shown that the most successful overall solution is based on a range of electrically high performing polymeric materials, custom-designed for specific applications. Critical material performance factors include excellent long-term resistance to premature ageing, whereby the material is expected to maintain its electrical and physical properties, thermal endurance (continuous operating at up to 105°C) and high UV stability over some 30 years of service.

In parallel with outstanding material performance is good design. The key to successfully preventing bridging or guano flashovers lies in understanding the problem. This means identifying the most vulnerable bare metal places that need insulating. The solution will vary depending on the precise nature of any problem (e.g. a cat bridging phase-to-ground on a MV breaker or a white stork perching atop a cross-arm and making contact with one or more phases). As such, the local substation or line engineer is key to collecting this information along with looking for tell-tale signs of past wildlife interactions, as discussed earlier.

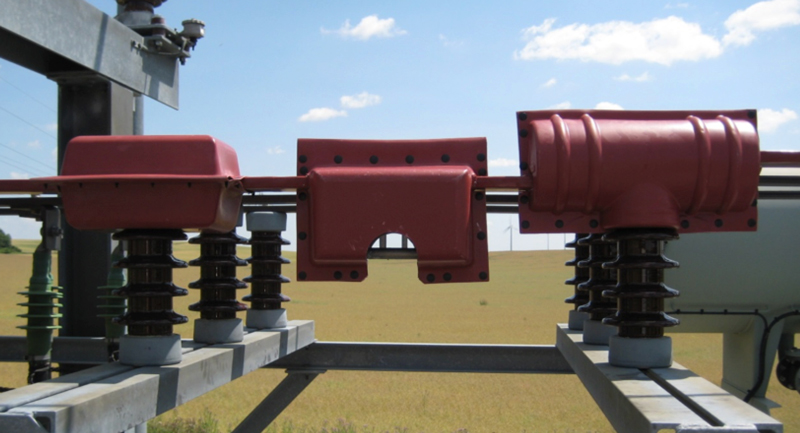

Vulnerable bare metal components can easily be insulated with either heat shrink or cold applied materials (or some combination of both) and typically up to 30 cm further along the busbar or overhead line than the farthest location of the known fault. This, however, is only general guidance and local knowledge should always be taken into account when available. In situations where there is bridging between phase and ground it is most common to protect both the equipment and wildlife by insulating the live side, e.g. busbar or conductor. It is also perfectly acceptable to insulate the ground side instead.

Long-Term Solutions

The following are examples of insulating vulnerable bare lines and substation equipment metalwork that had previously suffered multiple flashovers or were deemed at high risk of such events. In all cases, applying wildlife protective insulating materials effectively eliminated the problem while also allowing the wildlife to continue access.

Case 1: A white stork has a +2 m long wingspan. Thousands of these birds migrate each year from Africa to nest in Spain as well as central and south-eastern Europe. The nest is so big (up to 400 kg in weight and 2m in diameter) its presence will eventually cause flashover from accidental bridging between nest debris and conductor when conditions are wet or when birds bring conductive material (e.g. wire) to the nest Moreover, young birds that stray around the nest risk contacting the conductor. Insulating the bare metal fittings with a wraparound cover and the conductor with wraparound sleeving approx. 1.5 m from the nest in both directions offers both the bird and the power system long-term security.

Case 2: This crow’s nest in South Africa is precariously positioned on a 66 kV line between insulator and pole. The bird’s wingspan is sufficient to cause accidental bridging during landing or take off. Without the combination of conductor sleeve and wrap around connection cover, this bird/nest combination would at some point lead to flashover. The nest itself, while dry conditions last, might not cause problem. However once conditions become wet (rain, mist, fog, etc.) it is likely to short out enough of the insulator to cause flashover. Even in dry conditions, once the young birds are grown enough to move about, it is inevitable they will trigger a flashover.

Case 3: Laws in Germany require power utilities to implement countermeasures to prevent electrocution of birds and to protect both migratory and domestic species. The solution has been to use protective devices on 10/20 kV distribution mast tops. Insulation covers with an overall length of approximately 1.4 m prevent contact between birds and live conductors. There are many designs that can be attached using cable ties or live with insulated poles (hot-sticks). It is also possible to use transparent materials that allow aerial line inspection in terrain difficult to access. This solution may become more widely used as utilities increasingly introduce drones for maintenance.

Case 4: This insulator string demonstrates how the entire length can become heavily polluted with bird guano. The other photo shows that shielding the string makes it possible to keep the surfaces clean enough to never suffer pollution flashover due to wildlife. Here, it is critical that the material and design of the shield give many years of maintenance free service. This requires it be made of a high performance UV stable polymer and robustly secured at the top of the string. After seasonal rains, accumulated guano will wash away and fall harmlessly away from the string below. In those countries with extreme dry conditions and where it might rain heavily only once in several years, it is even more important to use a material that is also resistant to attack by the uric acid in the guano.

Case 5: A substation in Croatia has all its bare live metalwork insulated, and heat shrink tubing on busbars. Connection points have cold applied wrap-around covers that can be removed for maintenance or inspection and then re-applied. The problem behind this installation was the phase-to-ground clearance on the MV side of the transformer and bus network where the typical 40 cm air gaps were being bridged by cats, crows & pigeons.

Case 6: An ageing MV substation in central Athens suffered from entry by cats and pigeons. With numerous phase-to-ground clearances well below the nominal 40 cm, it therefore experienced multiple flashovers. The solution was to cover all vulnerable bare metalwork with a range of high performance polymeric covers, wrap-around sleeves and circular barriers that prevent cats climbing over the insulator and simultaneously touching the MV and ground sides.

Case 7:A MV substation in South Africa was built in an area of cleared scrub and trees inhabited by a troop of large monkeys. In its first year of operation it suffered 12 flashovers caused by monkeys that considered this their territory. The solution was to insulate all live bare metalwork across the site with a combination of heat shrink tubes and wraparound covers. Fully understanding the situation was critical to success on this site since phase clearances in some parts were approximately 1m which, if not for the monkeys, would not require additional insulation.

Case 8: A 20 kV substation in rural Germany was insulated against climbing animals such as martens and cats. Wraparound covers were cut on site to accommodate any unusual geometry, including the centre cover where a cut-out was added to allow access for an earth clamp in a relatively safe position. Covers that need such cutting in the field benefit from being made of a polymeric cross-linked material that will not propagate splits if cut roughly.

Conclusions

Awareness of the cost of wildlife-induced outages is growing and, with this, has come an increasing demand for reliable and robust solutions to protect both utility assets and the wildlife causing problems. Every power utility therefore has to contend with wildlife in the design and protection of its network. In finding the best long-term solutions, engineers must balance the need for exclusion/prevention and some tolerance of the wildlife in question.

The main causes of wildlife problems vary from region to region but the implications and basic design principles deployed are often the same. In addition to reliability enhancement and asset protection, it is clear that an unacceptable number of birds and other creatures are killed each year due to electrocution. Legislation to protect many species is increasing, with countries such as the U.S. and Germany leading the way. Wider EU legislation regarding protection of birds is now being planned.

As with any network component, the material chosen as a solution must not break down and cause a reliability problem of its own during the life of the system. With this in mind, it is critical to specify high performing materials similar to those used on other line components, including insulators and surge arresters. Wildlife induced outages are now entirely preventable.