Optimal Insulator Type & Dimensioning in Harsh Service Environments by Alberto Pigini

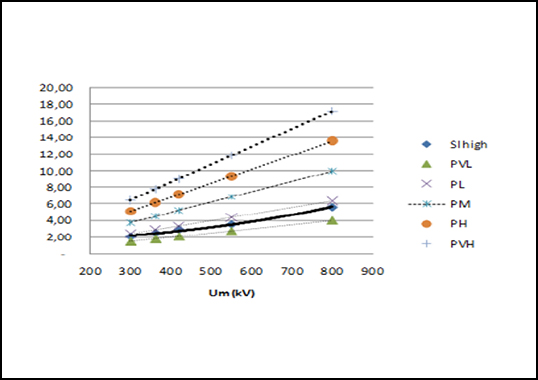

Harsh service environments such as deserts and coastal areas are highly demanding from the viewpoint of insulation selection and dimensioning. After analyzing general design criteria to be adopted in such environments, alternatives are analyzed and typically sub-divided into two main categories: non hydrophobic transfer material insulators, i.e. porcelain and glass, and HTM insulators, which include RTV-coated and composite types. Specifications for selecting insulators with regards to pollution in AC are already available and work is in progress towards their revision. These specifications are simplified to make their application easy yet they can offer sufficient information for preliminary design in cases where pollution does not determine insulator design, e.g. design of insulators for EHV and UHV AC systems with only moderate pollution constraints and where design and arcing distance are dominated by performance requirements under switching overvoltage. This presentation explains why the situation is much different when pollution dominates design. In this case, it is fundamental to select the proper insulator type and establish an accurate design under pollution since this will have great impact on overall system cost – either in terms of high investment costs or excessive operating costs.