Requirements & Challenges in Technology & Application of HV Cable Joints by Hansjoerg Gramespacher

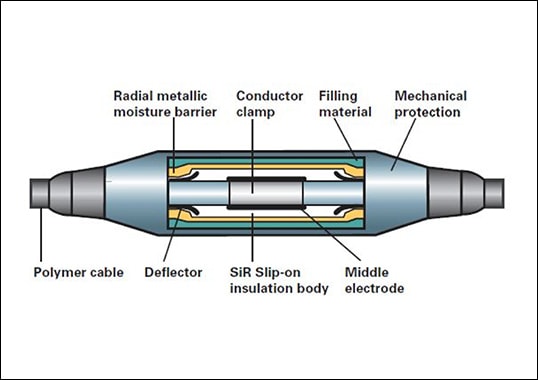

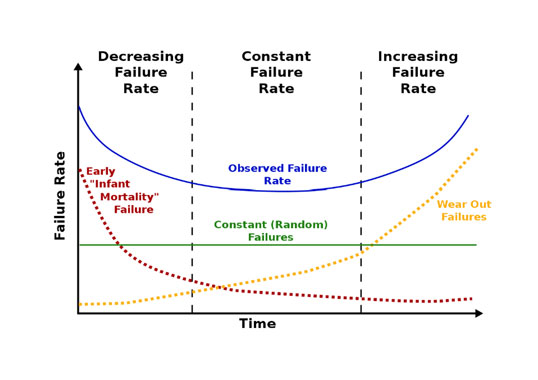

Pre-moulded joints for polymeric high voltage AC cables have been in operation for decades and their production, testing and application is a well-known technology. Nevertheless, there still exist a relatively large number of joint failures during type tests or pre-qualification tests, with about 30% failing in the first attempt. One reason for this is too high temperature in the joint during heat cycling tests required by international standards. This is often caused by a variety of possible errors during installation, making this an important topic to resolve. Another issue that has become important is temperature monitoring of HV cable systems using optical fibres. Distributed temperature sensing, together with software tools that allow conductor temperature of a power cable to be calculated, make real time thermal rating of a cable system possible. However, at joints, the thermal environment around the cable connector differs from that of the cable itself, making calculation of conductor temperature inside the joint more difficult. In combination with possible issues during installation, temperature inside the joint can be much higher than at the cable. This can lead to increased ageing of cable insulation inside joints and, in the worst case, to joint failure. This presentation reviews requirements in application of HV cable joints that are still under discussion, including thermal resistivity of joints and electrical losses at cable connectors. These parameters influence temperature inside a joint and therefore reliability of the entire cable system.