[inline_ad_block]

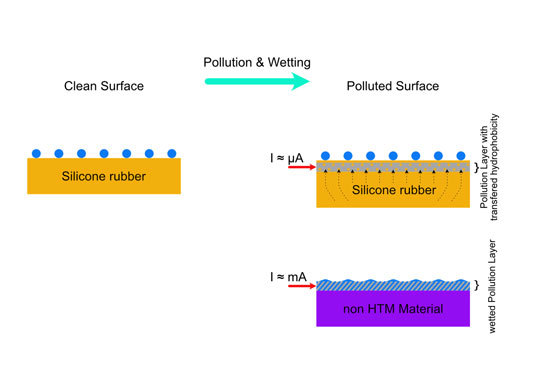

Leakage currents flow across the surface of polluted insulators under wet atmospheric conditions and link closely to resulting discharge phenomena. They have a range of characteristics that include maximum amplitude, number of pulses that exceed certain amplitudes, pulse frequency, harmonic component of wave shape, etc.

Due to their thermal effects, dry zones soon appear in locations where leakage current density is highest (e.g. at caps and pins of suspension insulators) and leakage current effectively stops. However, distribution of the potential along the insulator surface has changed with the two ends of the ‘dry zone’ able to withstand higher voltage. But once this dry zone fails to withstand the voltage, air puncture will occur along the surface and the result will be phenomena such as spark discharges, minor arcing and appearance of a leakage current pulse.

In the case of AC, one discharge pulse lasts only a few or tens of frequencies. For DC, pulse duration can also be calculated in milliseconds, however the interval between successive pulses will depend greatly on the weather. For example, under saturated or near saturated wetting, the interval between pulses can be several seconds or several minutes. But under less saturated environmental moisture, the interval between pulses can be tens or even dozens of minutes. If the weather is not wet, there may be no leakage current at all.

The extent of leakage current, of course, does not depend solely on wetting but also on insulator type, dimensions, operating voltage and pollution levels. Because insulator type, dimensions and required withstand in service are all specified under saturated moisture conditions, the extent of leakage current correlates closely with pollution and, in fact, can be used to characterize an insulator’s pollution level. Moreover, because installing on-line leakage current monitoring systems is relatively simple, there is now growing interest to use them not only for real-time monitoring of insulator pollution levels but also to trigger alarms in case of impending pollution flashover.

As a parameter to characterize pollution levels, leakage current has its advantages as well as disadvantages. One advantage, as mentioned, is ease of setting up on-line monitoring whereas a disadvantage is the high impact of weather conditions. For example, monitoring leakage current on-line will not be successful in areas experiencing prolonged drought. Moreover, even in areas with some moisture, this may not be at a sufficiently saturated level. Since leakage current relates to both pollution level and degree of wetting, analysis of signals collected only becomes meaningful if these conditions are taken into account.

Presently, research in China is focused on:

• Examining the relationship between leakage current and pollution accumulation, wetting, operating voltage as well as insulator type and geometry so as to propose various quantitative relationships;

• Developing more mathematical methods to analyze leakage current wave form and utilizing signal processing and analysis to better evaluate data in terms of time domain, frequency domain, phase and energy. Also, trying to find those leakage current parameters that relate most closely to insulator pollution accumulation and wetting as well as characterizing these;

• Developing improved devices for on-line monitoring that will collect large quantities of leakage current signals while also being able to perform all necessary statistical analyses.

Progress is now underway in all areas. For example, through extensive testing, the relationship between leakage current and pollution level as well as relative humidity (RH) has been obtained. Moreover, the impact on leakage current of such factors as fog, rain, condensation, melting ice, etc. has been studied.

The effect of non-soluble components as well as soluble salts on moisture absorption by pollutants is also a matter of some interest. If pollutants contain sugar, for example, they are able to absorb moisture at lower RH and so higher leakage currents and discharges can be detected. In this respect, findings can be obtained not only through testing but also by deriving the theoretical relationship between leakage current and parameters such as operating voltage, insulator dimension, surface conductivity and SDD.

On the basis of complete and reliable leakage current signals, model identification and fuzzy logic can be used to analyze data in terms of time domain, frequency domain, phase and energy – all the while trying to find the characteristics of leakage current that most closely correlate to pollution accumulation and wetting. However, there is still a way to go toward making such analysis more practical. At the moment, for example, the leakage current characteristic that most closely relates to pollution flashover voltage is still its maximum amplitude.

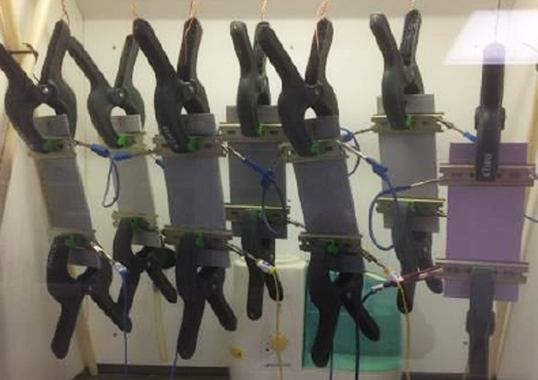

Tsinghua University developed a variety of leakage current measuring devices applicable to laboratories, substations and overhead transmission. Already nearly 100 such on-line devices are installed in different parts of the country and have generated extensive data that offers a basis to perform detailed statistical analysis of the leakage current. Other Chinese universities and also manufacturers have developed similar test instruments that are now being used in service to collect, process and analyze leakage current signals.

Although more research remains to be done, it can be stated that on-line measurement of leakage current offers excellent prospects for monitoring insulator pollution levels as well as risk of flashover.

Prof. Guan Zhicheng

Tsinghua University, Shenzhen Campus