Design Rules for Long Term Reliability of Composite Insulator Strings by Isaac Bohlken

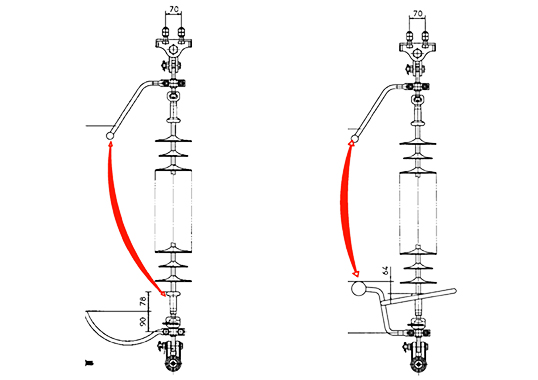

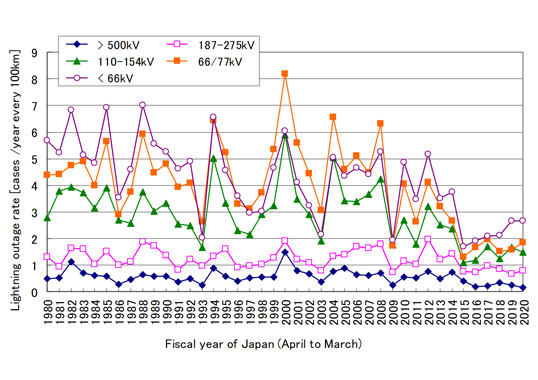

Long-term reliability of composite insulator strings is achieved by taking a holistic design approach with proper consideration of all the determining factors. Insulator strings are mechanical links between structures and conductors and also commonly the shortest path between energized and grounded elements of the line. Therefore, they are where electrical field gradients are highest and where power arcs are most likely to occur. One of the keys to longevity of composite insulator strings is avoiding continuous corona discharges on hardware as well as water droplet corona on insulator housings. Since both can have damaging long-term effects, electric field stress limits for both must always be controlled. This is achieved through appropriate design of hardware and use of field grading devices such as corona rings. Simulation is one way to evaluate electric field stresses but care must be taken to consider the larger context in which a string will operate in order to create a truly representative model. Moreover, it also has to be considered that corona rings are most exposed to power arcs due to their positioning. This presentation explains how understanding the current and duration of possible short circuit events is important when designing suitable corona rings and arcing protection for a string as well as in specifying the current carrying capacity of load bearing hardware.