Quality Assurance & Quality Control of HVDC Cable Systems by Marc Jeroense

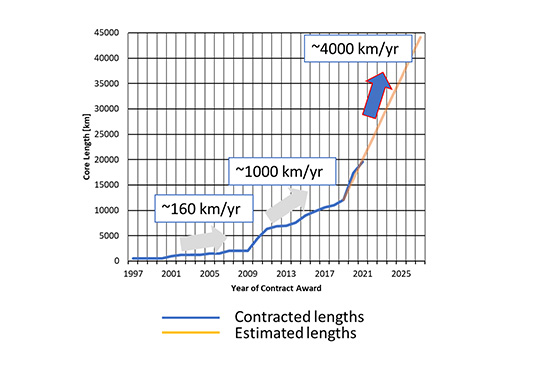

There has been a significant increase in the volume of yearly HVDC cable projects. At the same time, performance characteristics of these systems, such as voltage, power, temperature, cable length and grid criticality have also increased. Given decreasing design margins due to higher stresses and temperatures, there is a need for enhanced Quality Assurance and Quality Control. This presentation highlights these trends, discusses areas where more QA and QC are advisable and proposes ideas and methodologies toward this goal.