There’s a well-known proverb: “a picture is worth a 1000 words” and INMR has always set itself apart from other journals in the T&D field in terms of the number and variety of unique photos offered to readers. Of course, taking photos of an overhead line or substation is one thing. But being on the spot to capture an event that links directly with the topic of a particular article – that requires planning and dedication but mostly luck. Here some of our most interesting images covering 26 years of visits to power network across the globe.

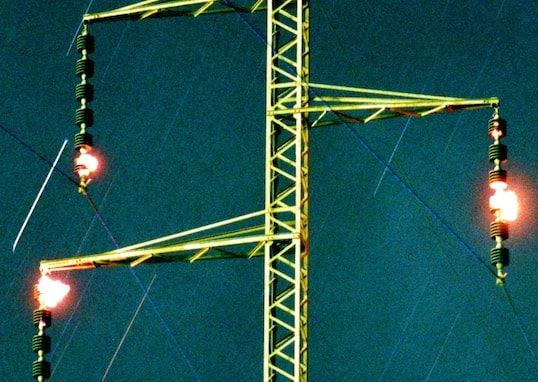

When customers complain of unreliable electricity supply, it’s rare to be able to capture the essence of the problem with a single snapshot. A large chemical works near the Dead Sea in Israel suffered from frequent outages, due in large part to a severe local pollution environment of alkali salts. A nighttime inspection of the main line that supplied the facility resulted in this remarkable photo that reveals partial flashovers in progress along the porcelain long rods.

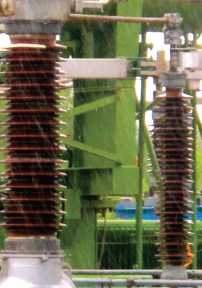

Anneberg was the name of a now-closed insulator research station located in southern-eastern Sweden and operated for years by Chalmers University of Technology. This was also the site of one of the first installations of composite-housed bushings, mounted in different configurations during the 1980s. The rainy and damp environment in the region soon resulted in appearance of substantial biological growths on the shaded lower portion of sheds. A similar problem – although more severe – was reported in the mid 1990s on 230 kV composite breaker bushings by a rural power utility in Florida. Research over the years by Professor Stanislaw Gubanski and colleagues, demonstrated that such growths should ideally be removed by water washing followed by alcohol since they create localized sites of moisture accumulation. However, notwithstanding their menacing appearance, these growths do not present any longterm danger of degrading the silicone housing material.

[inline_ad_1]

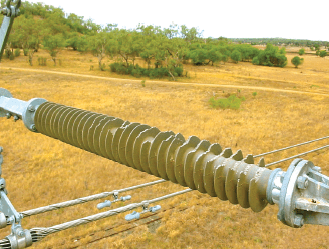

This one image has made composite insulator manufacturers around the globe shudder since it reveals in an instant one of the ‘Achilles heels’ of this otherwise brilliant technology. Australia is home to many species of exotic birds that sometimes find insulators a convenient place to sharpen and exercise powerful beaks. The problem has been so severe in certain areas that large numbers of insulators on new lines were found critically damaged even before energization. A number of techniques have been proposed to shield composite insulators from severe bird-pecking damage during the period between installation and energization, when this problem apparently lessens due to high electric fields that keep birds away. But none seems to have yet become industry standard.

The catastrophic failure of any porcelain-housed component (such as the transformer bushing shown in this image) can lead to ejection of lethal shards at velocities that make them a threat not only to people but also to other assets across a large radius. Explosive failures have occurred in many countries, such as this one at a substation in Crete a few years ago that caused over million Euros of collateral damage and was reported on in INMR shortly after it occurred. Fortunately, no one was nearby at the time since sharp pieces of porcelain were later found embedded in structures many meters away.

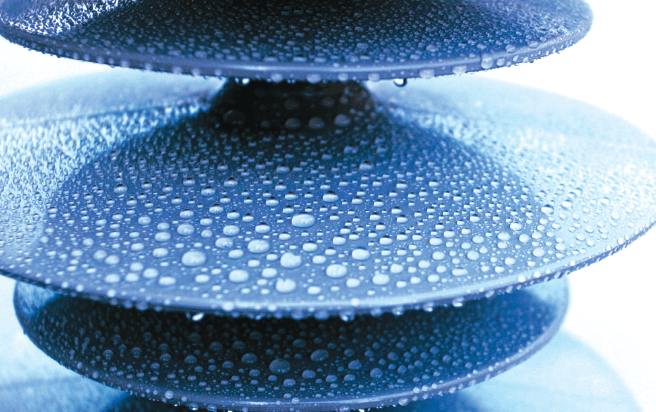

It may seem strange these days, but in the early 1990s few power engineers had ever heard of or cared much about that tongue twister term, ‘hydrophobicity’. However, this has changed dramatically as silicone vaulted from relative obscurity in the T&D field to becoming a mainstay of HV line and substation insulation, comparable to porcelain or glass. An insulator with the excellent hydrophobic behavior shown in this image (Class 1) should provide peace of mind to engineers, with its implied assurance that no matter what the pollution and wetting situation, it will resist formation of conductive paths and excessive leakage current.

[inline_ad_2]

If pecking silicone insulators was not enough to make power engineers want to hurl stones in the direction of large birds, an even more widespread ornithological threat is demonstrated by this image. Bird excretions (better known by the euphemism ‘streamers’) sometimes launch massive volumes of conductive material directly onto insulator surfaces or across air gaps, often triggering flashover in an instant. Indeed, most outages with no apparent cause are usually attributed to birds.

Teflon (PTFE) housed composite insulators were introduced in Italy in the earliest days of this technology, going back some 40 years. Unfortunately, in spite of their many potential benefits, early designs suffered from a serious and even fatal flaw – namely wedge-type end fittings unable to protect the core rod against penetration of external moisture as well as acids generated by corona. The brittle fracture shown in this photo records one of the very first such failures

Composite hollow core insulators were developed in Hungary from their earliest days and the associated production technology was subsequently transferred to Western Europe though licensing agreements. Successful practical application of this technology, however, required the capability to produce sometimes massive FRP tubes which provide the mechanical strength needed across a range of applications up to as high as 1000 kV. This photo, taken through the length of such a tube, gives an indication of the complex engineering involved winding resin-impregnated fiberglass rovings at pre-determined angles onto a steel mandrel so as to generate a tube strong enough to meet the needs of the application.

[inline_ad_3]

Much has been written about the massive winter storm that coated conductors and towers in eastern North America with up to 80 mm (3 inches) of ice. The results were catastrophic, especially in Québec where hundreds of lattice transmission structures toppled. This image, taken only hours after the event, captures the macabre scene as tower after tower along a 735 kV line lie in a crumpled heap, the sub-conductors stretched out over the icy ground. But perhaps even more eerie is that standing right alongside is another such line of seemingly identical design yet virtually unscathed by the calamity.

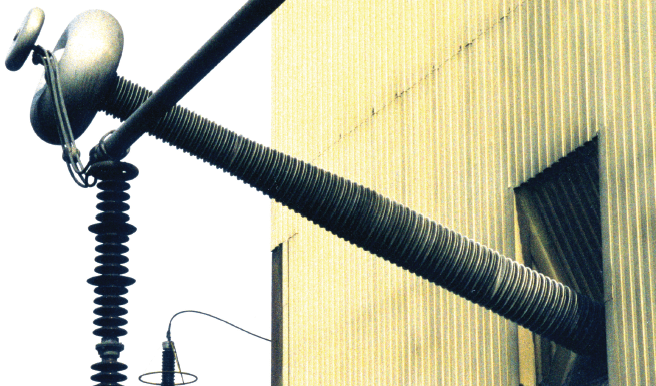

It has long been known that wall bushings can be highly vulnerable to pollution flashovers from the phenomenon of uneven pollution deposition, especially if there is no roof overhang to limit wetting by rain. This is a photo of a massive porcelain bushing installed during the late 1990s at the ±500 kV Nanqiao Converter Station near Shanghai and exposed to high ESDD levels from nearby chemical works (since relocated). One can quickly appreciate from this image just how uneven the pollution deposition can be along such a profile, tilted at an angle and partly shielded from wind by the building.

[inline_ad_4]

Aerodynamic glass disc insulators find widespread application in environments such as deserts, where the wind is relied on to do all the natural cleaning due to the absence of rain. However, this photo from a test station in Tunisia clearly illustrates that even these insulators can accumulate significant contamination that remains unaffected by natural cleaning.

As discussed earlier, brittle fracture is a well-documented phenomenon affecting composite insulator designs whose external sealing mechanism no longer prevents moisture from entering into internal interfaces, typically near the end fittings. The fracture in such instances is typically planar, with smooth surfaces. The recent failure illustrated by this photo, however, occurred near the center of the insulator and seems due to an entirely different and still to be researched mechanism believed related to improper bonding of the housing to the rod.

In the early hours of January 17, 1994 an earthquake, measuring 6.6 shear wave magnitude on the Richter scale, struck a section of Los Angeles. According to engineers at the municipally-owned utility, damage to the local power system exceeded $ 75 million, especially at the Rinaldi Substation, an important 230 kV switching point in the grid. Apparently, about half of this damage related directly to broken porcelain and in particular post insulators and 500 kV transformer bushings. This event prompted the affected utility to begin a serious assessment of applying composite insulators more widely to limit impact of future seismic events.

Greater weight in power engineering almost always translates into higher costs for handling and foundations. It is also a major factor in designing for good seismic performance. This photo, captured at ABB’s Micafil bushings plant in Switzerland during the mid 1990s, shows in an instant one of the principal advantages of composite insulators over traditional porcelain housings. Here, a middle age worker easily transfers a housing from stock to the final assembly area on his shoulders. Of course, most such factories are equipped with forklifts for other purposes but not having to rely on them, as in this instance, demonstrates production flexibility.

Widespread pollution flashovers under winter fog conditions were the principal factor driving application of millions of silicone composite insulators on Chinese transmission lines, starting in the 1990s. This nighttime image from South China provides excellent photographic evidence of how such flashovers can develop along glass tension and jumper support strings.pecific creepage and shed geometry. Still, while the erosion here may look menacing, there are known methods to repair such damage.

The glass suspension string in this photo is in operation in southern Spain. Yet most experts will agree that this unusual arrangement of different profiles offers no real benefit, except perhaps under icing, which is not a threat in this particular service environment. Against risk of flashover from bird streamers, the configuration is less than ideal since the wider aerodynamic profile would then be better placed at the top of the string. As for pollution performance, the two profiles will accumulate different contamination levels due to their different geometries, which in turn will negatively impact even distribution of E-field. While under clean conditions the result might not be too worrisome, depending on similar hardware on both types, the obvious question is ‘why do it at all?’, especially since aerodynamic glass discs are usually more costly.

Combining different technologies in a single insulator string is not common but, as in this image taken in north-eastern Brazil, is still utilized. In this case, the motivation for the unusual configuration is vandalism with the porcelain discs installed to ensure that the entire string would not be destroyed by rock throwing.

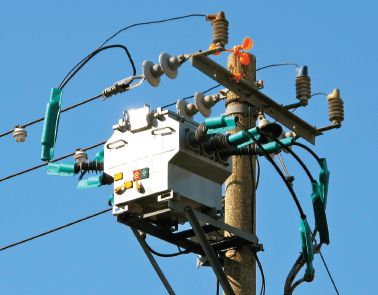

Recent service experience across several countries suggests that as much as 70 to 80% of all outages affecting overhead lines can be directly attributed to birds. At the same time, countless birds succumb each year to electrocution on power networks across the globe. This image of pole top equipment and components, taken near the beach in the Chinese coastal city of Qingdao, shows at a glance that there are effective ways to deal with both problems.

Rainfall is often seen as a natural cleaning mechanism for porcelain insulators. But it can also act as a trigger for problems the first time it occurs after prolonged dry periods, particularly in areas with heavy maritime pollution. This image, taken at a new 90 kV substation of a wind power plant along the North African coast, captures just a small example of arcing that almost overwhelmed the substation’s insulation one rainy September day – the first rainfall after the long dry summer. The event also highlighted that insulators at the substation may not have been ideally dimensioned for this challenging service environment.

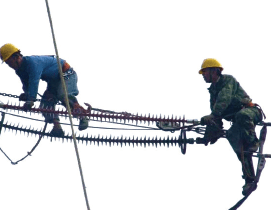

It is no odd coincidence that while composite insulators now strongly dominate suspension applications on Chinese transmission lines (especially at UHV), associated tension strings are almost all either of porcelain or glass. The reason for this anomaly can be seen in this image since Chinese engineers worry that composite tension strings – and particularly the long ones – will suffer permanent damage due to linemen crossing them to access the conductor for repairs. Research at a Chinese university simulated the impact of lineman boots crossing insulators several times and found no trace of damage. But perception is often a more powerful motivator than demonstration and this situation does not seem likely to change soon. for this challenging service environment.